Custom Printed Circuit Board helps electronic products to achieve high performance and miniaturization

With the rapid development of electronic technology and the increasing demand for high-performance devices from consumers, Custom Printed Circuit Board (custom printed circuit board, referred to as PCB) is becoming a key driver of the electronics industry. It not only meets the miniaturization needs of equipment design, but also plays an important role in improving performance, optimizing costs and driving innovation.

Custom PCB: The cornerstone of high-performance electronic devices

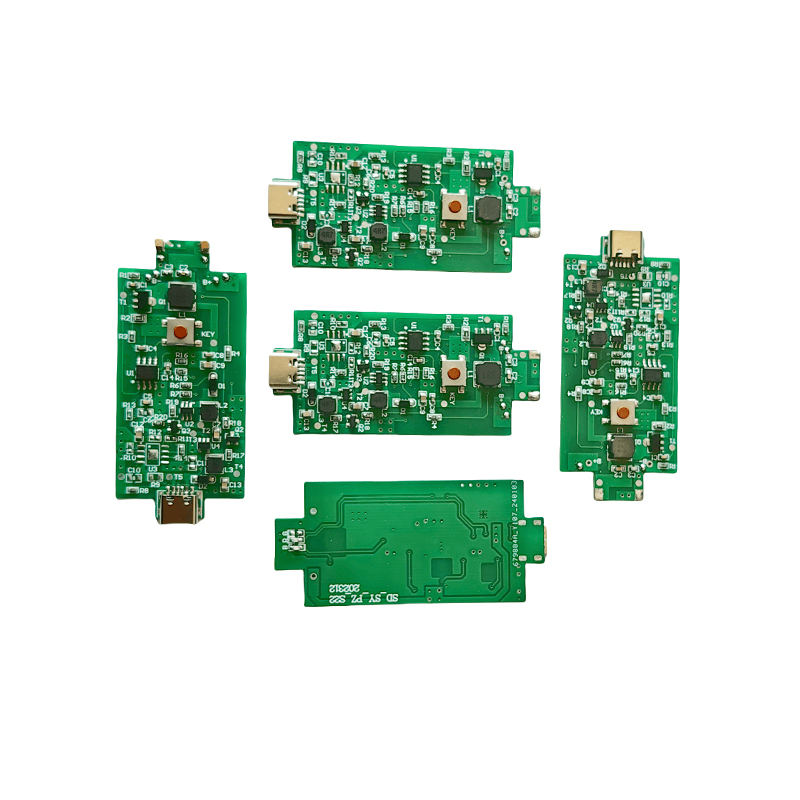

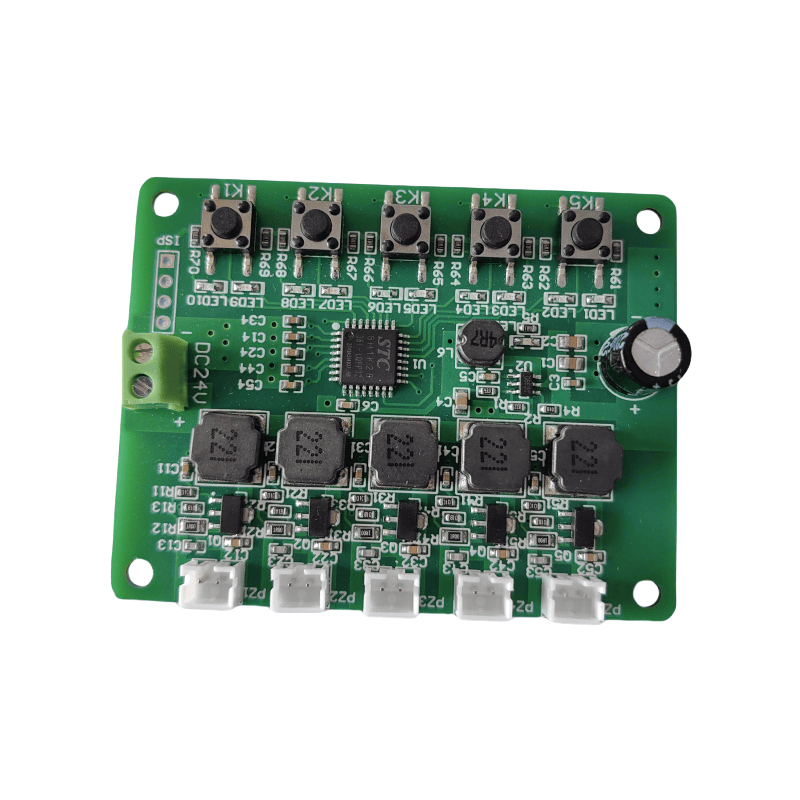

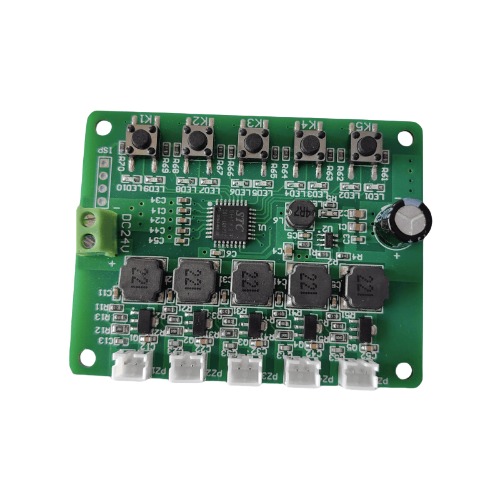

Traditional standard PCBs can no longer fully meet the complexity and performance requirements of modern electronic products. Custom PCBs can design circuit boards with special functions and high performance according to specific application needs. Custom PCBs can significantly improve device performance by optimizing wiring, reducing signal interference and improving circuit reliability.

For example, in 5G devices, intelligent hardware driven by artificial intelligence, and high-frequency communication devices, customized PCBs can support high-density assembly and high-speed signal transmission, ensuring the stable operation of the equipment in complex environments. In addition, its highly flexible design can add more functional modules to the circuit board while ensuring a reduction in overall size.

Technical innovation in miniaturized design

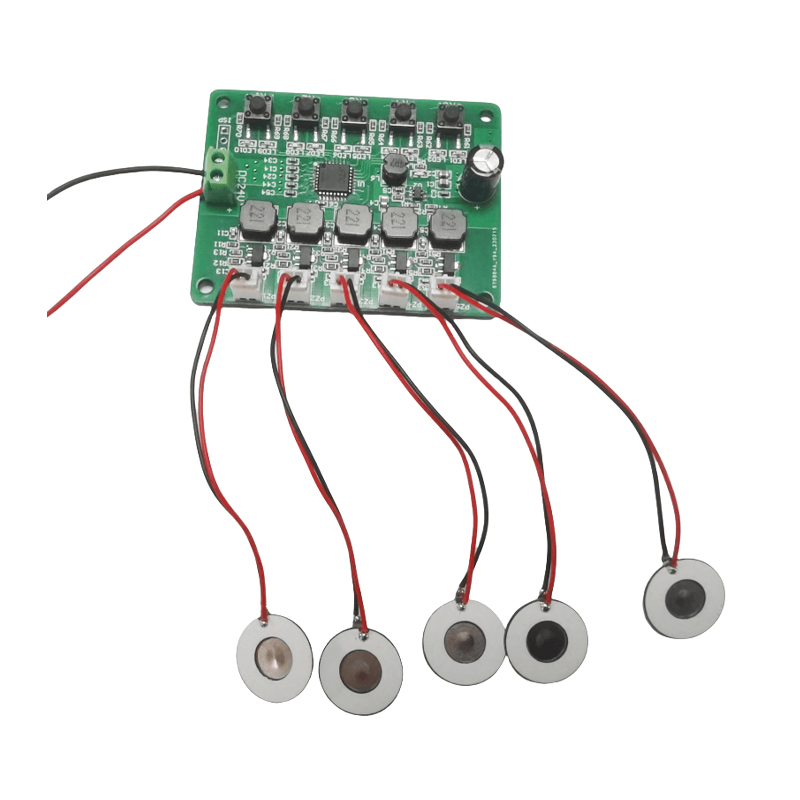

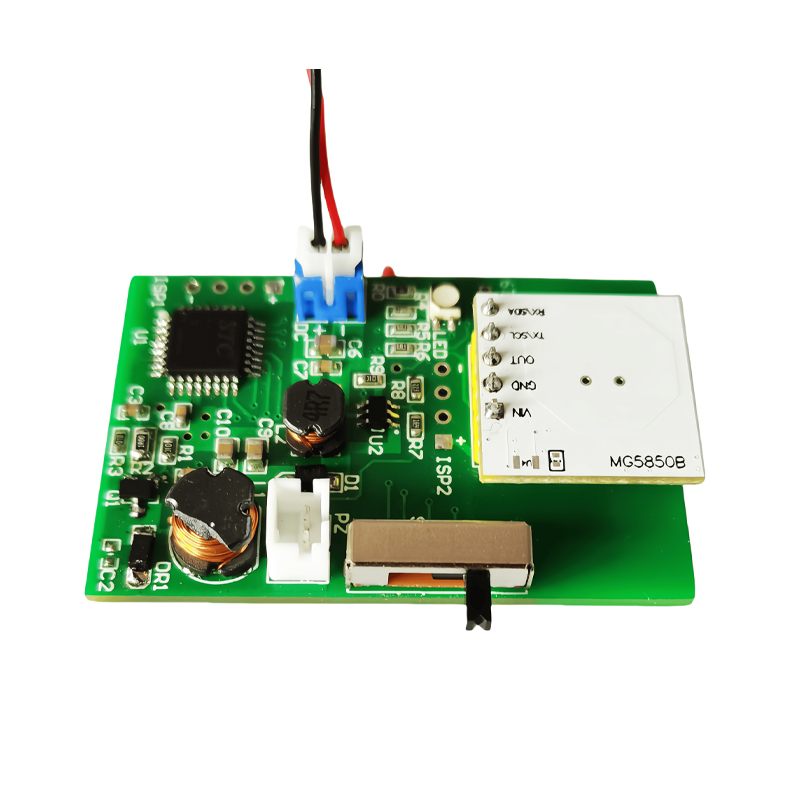

Miniaturization of electronic products is an important trend in today's industry, and Custom PCB is the key technology to achieve this goal. With advanced multi-layer design and flexible materials applications, custom PCBs can significantly reduce the device size and optimize internal space layout.

For example, flexible PCBs (FPCs) can adapt to device housings of various complex shapes, providing better solutions for wearable devices, medical implants and other portable electronic devices. At the same time, the application of ultra-thin materials and high-density interconnection (HDI) technology has further promoted the refinement of PCB design.

Reduce manufacturing costs and improve production efficiency

Although the initial design cost of customized PCB is relatively high, its optimization effect on production efficiency and overall cost cannot be ignored. Through modular design and precise functional customization, enterprises can reduce waste and reduce material and labor costs. At the same time, the ability of mass production makes custom PCB a cost-effective choice in modern electronic manufacturing.

In addition, with the introduction of automated production equipment, the accuracy and consistency in the PCB manufacturing process have also been significantly improved. This not only improves product quality, but also shortens the time to market, bringing more competitive advantages to the company.

Future trends that promote industry development

In the future, with the further development of the Internet of Things, smart homes, driverless cars and other fields, the demand for Custom PCB will continue to grow. More complex functional requirements and higher performance standards will prompt PCB manufacturers to continue to innovate in technology. For example, utilizing 3D printing technology and advanced materials to develop more complex circuit structures, or optimizing circuit designs through AI to improve productivity and product performance.

Custom Printed Circuit Board is driving the high performance and miniaturization of electronic products through its unique design and manufacturing advantages. Whether meeting consumer needs or promoting industry technological innovation, custom PCB has become an indispensable and important part of the electronics industry.

English

English 中文简体

中文简体