Functional expansion and intelligent upgrade of Aromatherapy Humidifier Misting Tray PCB Board

In the safe operation guarantee system of humidifiers and aromatherapy humidifiers, the water level monitoring and protection mechanism carried by the mist tray PCB board plays a key role. Through innovative circuit design and detection technology, it builds a set of precise water level sensing and emergency treatment systems, effectively avoiding the risk of dry burning caused by water shortage, and at the same time laying the foundation for the stable and long-term operation of the equipment.

Iterative upgrade of water level detection technology

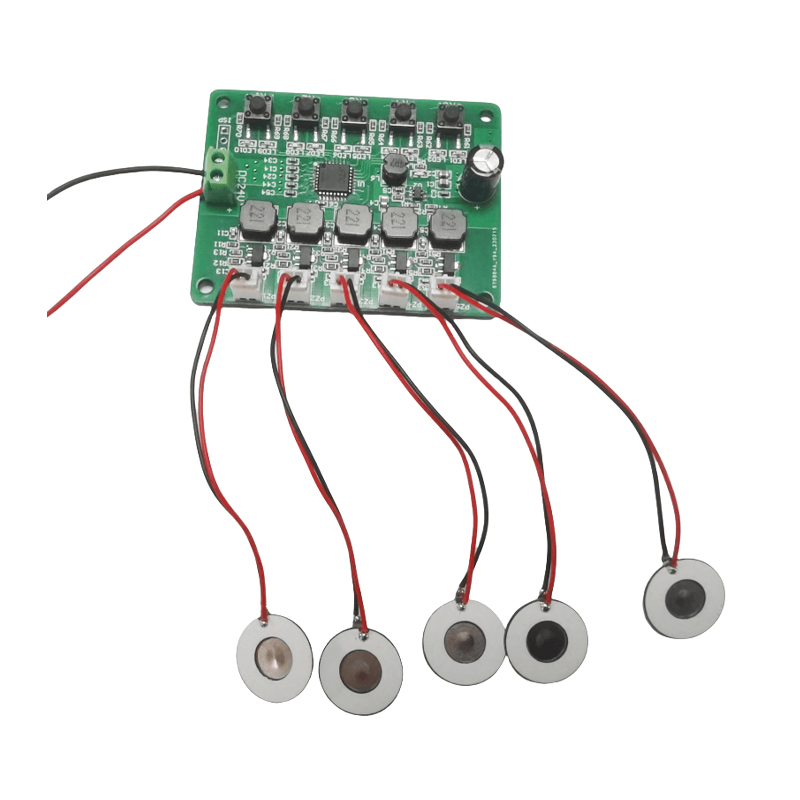

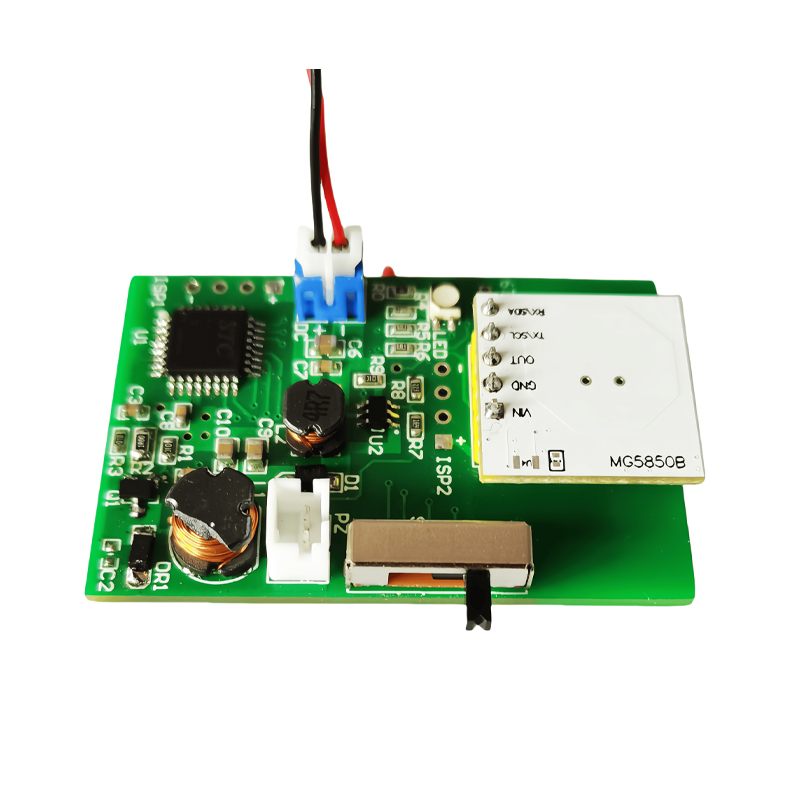

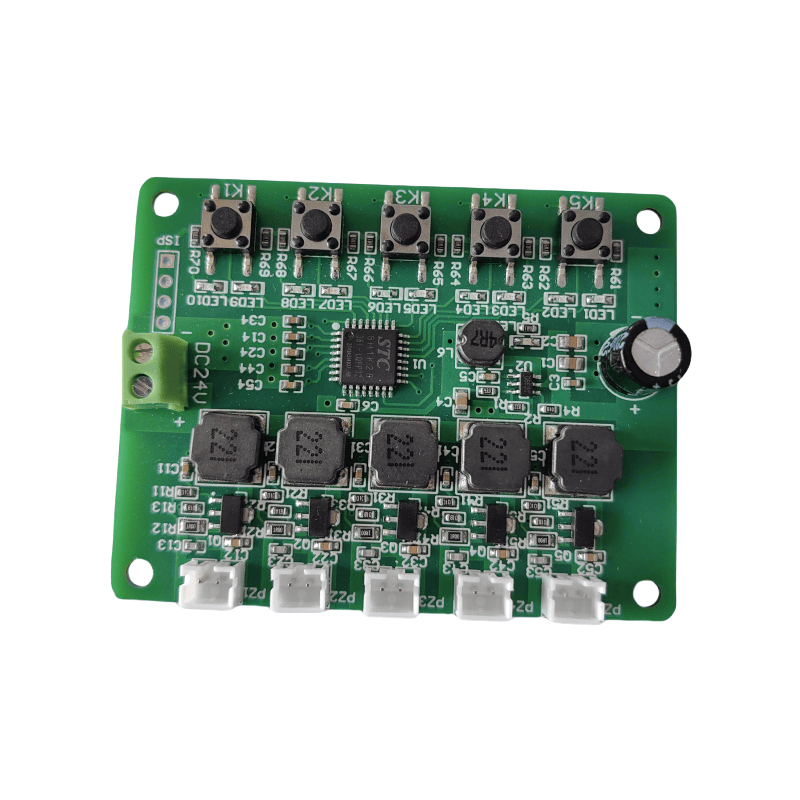

The water level monitoring of traditional humidifiers mostly relies on mechanical sensing devices, which trigger switch actions by physical contact with water level changes. However, the mechanical structure is easily affected by scale and impurities, resulting in jamming or poor contact, resulting in monitoring failure. The emergence of Aromatherapy Humidifier Misting Tray PCB Board brings technological innovation. Its integrated electrode or sensor water level detection circuit uses electrical signal changes as the basis for judgment to achieve non-mechanical water level monitoring. Electrode detection sets two or more electrodes in the water storage chamber of the equipment. When the water level submerges the electrodes, the conductivity of water forms a path between the electrodes, and the PCB board senses the water level accordingly; sensor detection uses infrared, ultrasonic and other sensors to accurately determine the water level by using the difference in the propagation characteristics of light or sound waves in air and liquid. These two technologies get rid of the limitations of mechanical structure and greatly improve the stability and reliability of water level monitoring.

Intelligent advancement of touch water detection technology

With the development of technology, some advanced aromatherapy humidifier misting tray pcb board introduces touch water detection technology, which uses the principle of capacitive sensing to achieve non-contact water level detection. This technology is based on the difference in capacitance values of capacitor plates in different media, and sets a capacitive sensing area on the PCB board. When the water level rises and approaches the sensing area, water as a dielectric changes the capacitance value. The PCB board captures this change through the built-in capacitive detection circuit to accurately determine the water level status. Compared with traditional electrode detection, touch water detection technology does not require the electrodes to be immersed in water for a long time, avoiding electrode oxidation and corrosion problems, and effectively extending the service life of the detection components. The non-contact detection method also makes water level monitoring more sensitive. Even small water level fluctuations can be quickly sensed, providing a more timely response for the safe operation of the equipment.

Logical judgment and emergency handling

The water level monitoring system of the atomizer tray PCB board does not exist in isolation. It works closely with the power supply circuit of the equipment to form a complete dry burning protection system. When the water level detection circuit captures that the water level has dropped to the preset threshold, the detection signal is immediately transmitted to the core control unit of the PCB board. The control unit makes a judgment through a pre-set logic program. Once it is confirmed that the water level is lower than the safe value, it quickly issues an instruction to cut off the circuit loop that supplies power to the atomizer. This process is completed in a very short time, from water level detection to power-off response, relying on the PCB board's efficient signal processing and instruction execution capabilities to ensure that the atomizer stops working immediately when it is short of water, and eliminates the occurrence of dry burning from the source of the circuit. This active protection based on the circuit level is more timely and reliable than the traditional method of relying on external alarms to prompt users to handle manually, and builds a solid line of defense for the safe operation of the equipment.

The dual value of the water level protection mechanism

Accurate water level monitoring and rapid protection response not only significantly improve the safety of humidifiers and aromatherapy humidifiers, but also have a positive impact on the overall life of the equipment. Avoiding dry burning means that key components such as atomizers and heating elements will not be damaged by overheating, reducing the risk of component aging and failure due to high temperature. Advanced water level detection technology reduces frequent starts and stops caused by misjudgment or monitoring failure, making the equipment run more smoothly. New detection methods such as touch water detection technology reduce maintenance needs, and there is no need to regularly clean the oxidation electrode, reducing the user's use cost and maintenance burden.

English

English 中文简体

中文简体