Introduction

In the modern industrial landscape, spraying systems are crucial components across a wide array of applications, including manufacturing, agriculture, and healthcare. Efficient atomization in these systems is paramount to achieving optimal spray patterns, reducing waste, and improving overall performance. Traditional atomization methods, while effective in certain contexts, often face limitations when it comes to precision and control. The emergence of piezo atomization chips has revolutionized this field by offering enhanced control, precision, and efficiency.

What Are Piezo Atomization Chips?

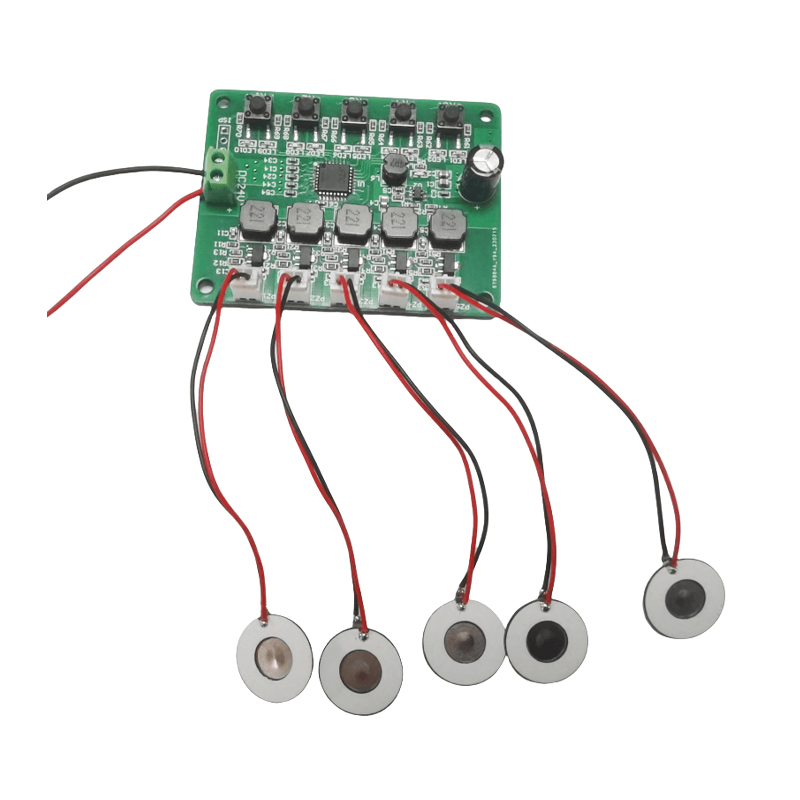

Piezo atomization chips are advanced components used in modern spraying systems that utilize piezoelectric technology to enhance the atomization process. The core of this technology lies in the piezoelectric effect, where certain materials generate an electric charge when subjected to mechanical stress. In piezo atomization chips, this effect is harnessed to vibrate a thin membrane or surface at high frequencies, which in turn helps break liquid into fine droplets. This process produces a highly controlled and uniform spray pattern, making it ideal for applications requiring precision, such as in fuel injection, coating, and medical nebulizers.

How Piezo Atomization Chips Work

Piezo atomization chips function by converting electrical energy into mechanical energy using the piezoelectric effect. When an electrical signal is applied to the chip, the piezoelectric material undergoes a rapid expansion and contraction, creating vibrations. These vibrations are then transferred to a liquid, causing it to break up into small, uniform droplets.

In a typical spraying system, the atomization process is crucial for ensuring the even distribution of the sprayed material. The finer the droplets, the more uniform and effective the spray becomes. By using piezo atomization chips, the spraying system can achieve finer droplets, thus improving the quality and efficiency of the spray. This process is often much more efficient than traditional methods, which rely on high pressure or mechanical force to atomize the liquid.

Key Advantages of Piezo Atomization Chips

Improved Precision and Control

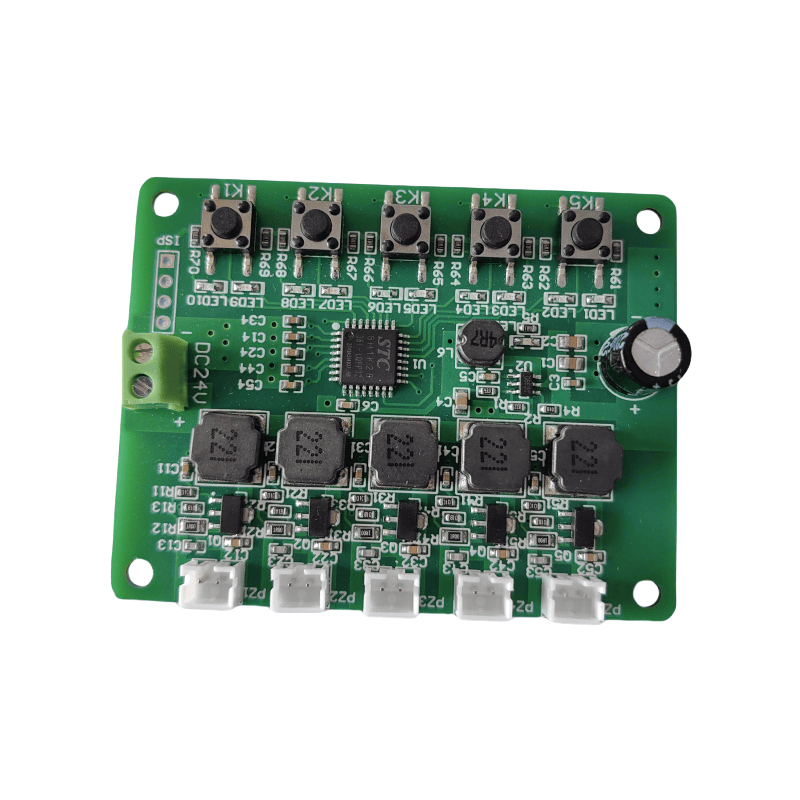

Piezo atomization chips allow for precise control over the spray pattern, enabling applications that require exact placement and distribution. The high-frequency vibrations generated by the piezoelectric materials ensure uniform droplet size and distribution, making them ideal for applications in industries such as printing, coating, and agriculture, where precision is critical.

Reduced Wastage

The efficiency of piezo atomization chips in producing fine droplets means that less material is wasted. Traditional atomization methods often result in large droplets or over-spraying, leading to waste. With piezoelectric atomization, the liquid is better utilized, ensuring that only the required amount of material is applied to the target area.

Enhanced Energy Efficiency

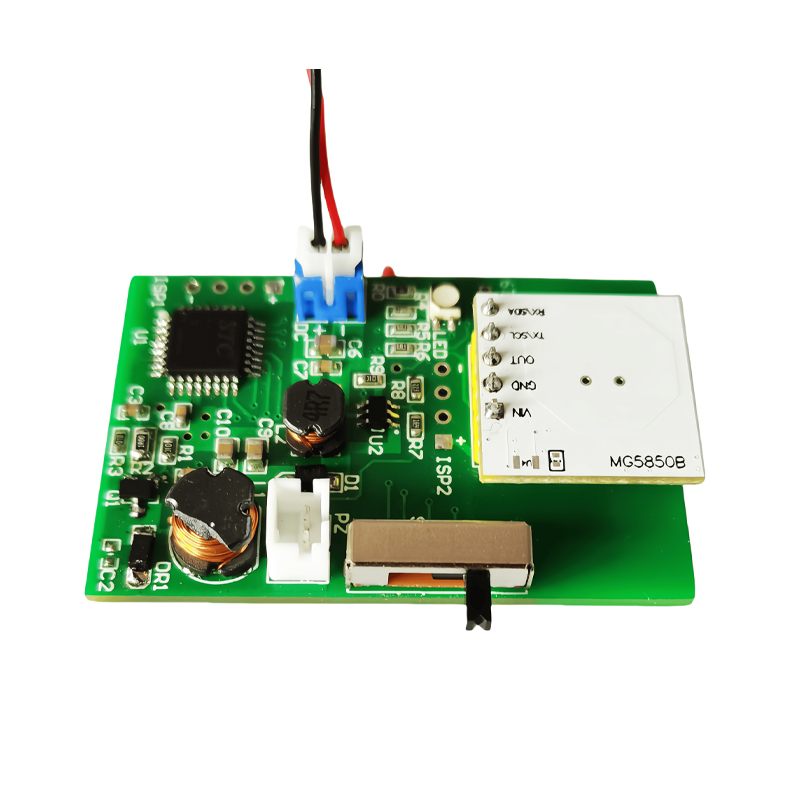

Piezo atomization chips are known for their energy efficiency. Since they rely on low power to generate high-frequency vibrations, they require significantly less energy compared to conventional methods that rely on high-pressure pumps. This not only reduces operational costs but also contributes to the overall sustainability of the system.

Smaller Footprint

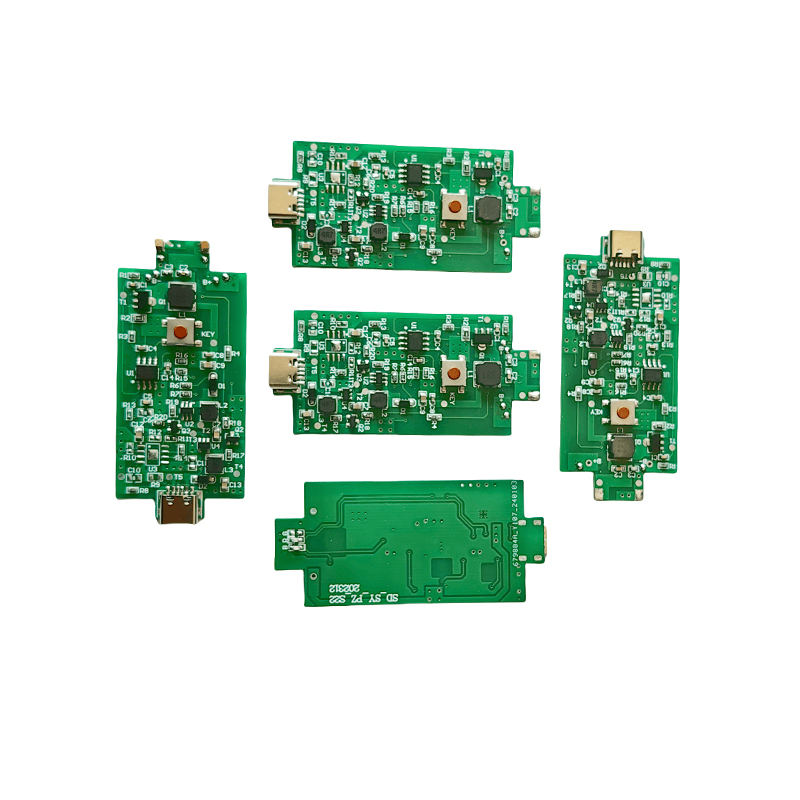

Piezo atomization chips are compact in size, making them ideal for applications where space is limited. Their small form factor allows them to be integrated into smaller, more compact spraying systems without sacrificing performance.

Longer Durability and Reliability

The design and materials used in piezo atomization chips contribute to their durability and longevity. Unlike traditional atomizers that rely on moving parts that can wear out over time, piezoelectric chips have fewer mechanical components, leading to a longer service life and reduced maintenance requirements.

Applications of Piezo Atomization Chips

Piezo atomization chips are used across various industries to improve the efficiency and effectiveness of spraying systems. Here are a few examples of their applications:

Agriculture

In agriculture, piezo atomization chips are used in precision spraying systems for pesticides, herbicides, and fertilizers. By producing fine, uniform droplets, these systems reduce the amount of chemicals used, minimize drift, and improve the effectiveness of the application.

Manufacturing

Piezoelectric atomization is used in coating and painting applications, where a consistent and uniform layer is critical. These chips ensure that coatings are applied smoothly and evenly, reducing material waste and improving the overall quality of the finish.

Fuel Injection

In the automotive industry, piezo atomization chips play a key role in fuel injection systems. By atomizing fuel more efficiently, they help improve combustion efficiency, reduce emissions, and increase fuel economy.

Medical Devices

In medical devices, piezo atomization chips are used in nebulizers for drug delivery. Their ability to create fine mist droplets allows for better absorption of medication, particularly in respiratory treatments.

3D Printing

Piezo atomization chips are also making their mark in the world of 3D printing, especially in inkjet-based systems where high precision and fine material deposition are required. These chips enable more accurate and detailed printing processes, leading to higher-quality printed objects.

How Piezo Atomization Chips Improve System Efficiency

-

Enhanced Droplet Size Control

One of the primary benefits of piezo atomization chips is their ability to control droplet size with high precision. This is particularly important in applications where fine mist or spray is required for optimal coverage and performance. By ensuring consistent droplet sizes, piezo atomization chips help improve the uniformity of the spray, which is critical for achieving desired results in applications like coating or pesticide spraying. -

Faster Response Times

The speed at which piezo atomization chips can adjust their spray output is a significant advantage. The high-frequency vibrations allow for quicker adjustments to spray patterns, making the system more responsive to changing requirements. This can result in increased throughput and efficiency in manufacturing or agricultural spraying. -

Minimized Overspray

Traditional spraying methods often result in overspray, leading to wasted material and potential environmental hazards. Piezo atomization chips minimize overspray by generating smaller, more controlled droplets. This ensures that the material is applied only where it is needed, reducing waste and environmental impact.

Comparison with Traditional Atomization Systems

| Feature | Traditional Atomization | Piezo Atomization Chips |

|---|---|---|

| Precision | Moderate | High |

| Energy Consumption | High | Low |

| Material Wastage | High | Low |

| System Size | Larger | Compact |

| Durability | Moderate | High |

| Maintenance | Frequent | Low |

FAQ

1. How do piezo atomization chips improve the spraying efficiency?

Piezo atomization chips enhance spraying efficiency by providing precise control over droplet size and distribution, reducing material waste, and improving energy efficiency.

2. Can piezo atomization chips be used in both small and large-scale systems?

Yes, piezo atomization chips are highly versatile and can be used in both small, compact systems and large industrial applications, thanks to their small size and high performance.

3. Are piezo atomization chips more energy-efficient than traditional systems?

Yes, piezo atomization chips are more energy-efficient compared to traditional atomization methods, as they require less power to generate high-frequency vibrations for atomization.

4. What industries benefit most from piezo atomization chips?

Industries such as agriculture, manufacturing, automotive, healthcare, and 3D printing benefit significantly from piezo atomization chips due to their precision and efficiency.

5. Do piezo atomization chips require frequent maintenance?

No, piezo atomization chips have fewer moving parts compared to traditional systems, making them more durable and requiring less maintenance.

Conclusion

Piezo atomization chips represent a breakthrough in spraying technology, offering significant improvements in efficiency, precision, and energy consumption. By enabling finer, more controlled droplets, these chips optimize the use of material and minimize waste, while also providing long-term durability and low maintenance costs. Their versatility and performance make them invaluable in industries ranging from agriculture to healthcare, where efficient spraying is critical.

English

English 中文简体

中文简体