With the continuous growth in global demand for precise medical nebulization therapy, the core component of medical nebulizers—the medical mesh piezo atomizer disc—has become a focal point in the industry. As a key element in next-generation nebulization systems, it enables high-frequency vibration and precise mist control. Its technological advancement is driving iterations of portable nebulizers, medical mesh nebulizers, ultrasonic nebulizer discs, and reshaping the technical roadmap of the inhalation therapy market.

Expanding Medical Nebulization Demand Drives Rapid Growth of Core Components

Global respiratory disease prevalence has shown a long-term upward trend, particularly among children and the elderly. Inhalation therapy is recognized for its convenience and safety. Compared to traditional jet nebulizers, new-generation devices that incorporate mesh atomizer plates, mesh nebulizer spare parts, and ultrasonic mesh transducers are lighter, consume less power, and can produce uniform fine mist through medical atomizing mesh.

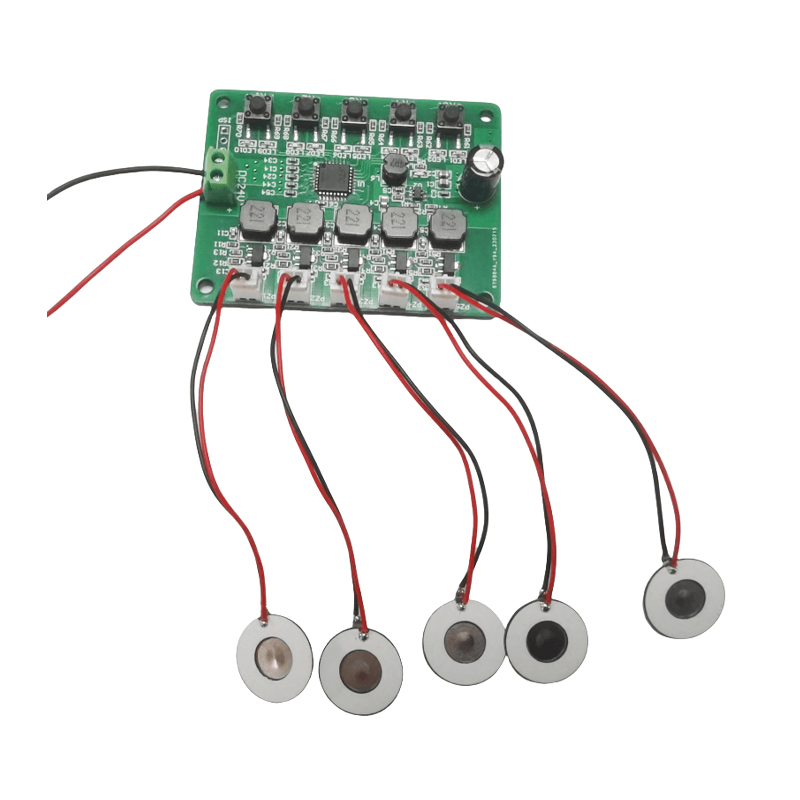

The medical mesh piezo atomizer disc generates fine mist by rapidly vibrating a piezoelectric plate at ultrasonic frequencies, forcing liquid through micro-perforations. This makes it the core component in portable and home-use devices. Market demand for lightweight, low-noise, and high-efficiency healthcare nebulization systems continues to rise, prompting manufacturers to expand capacity and accelerate technological innovation.

Technological Development: Systematic Upgrades from Microstructure to High-Frequency Driving

Recent advances in piezoelectric mist maker discs focus on three areas: micro-hole structural optimization, high-frequency driving stability, and corrosion-resistant materials. Among them, micro-hole fabrication is particularly critical, as the precision of the micro-perforations directly affects aerosol particle uniformity and the performance of inhalation therapy devices.

Micro-Hole Fabrication Improvements

Early inconsistencies in micro-hole size have largely been resolved. Current medical mesh piezo atomizer disc manufacturers focus on optimizing micro-hole patterns to enhance mesh atomizer plate atomization efficiency while maintaining low power consumption.

High-Frequency Driving Stability Enhancement

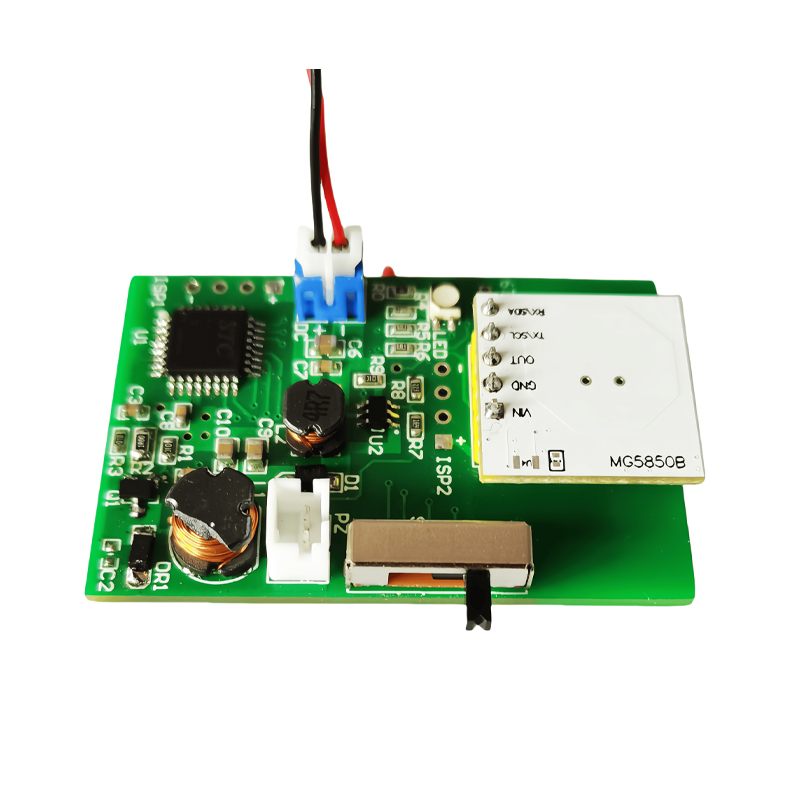

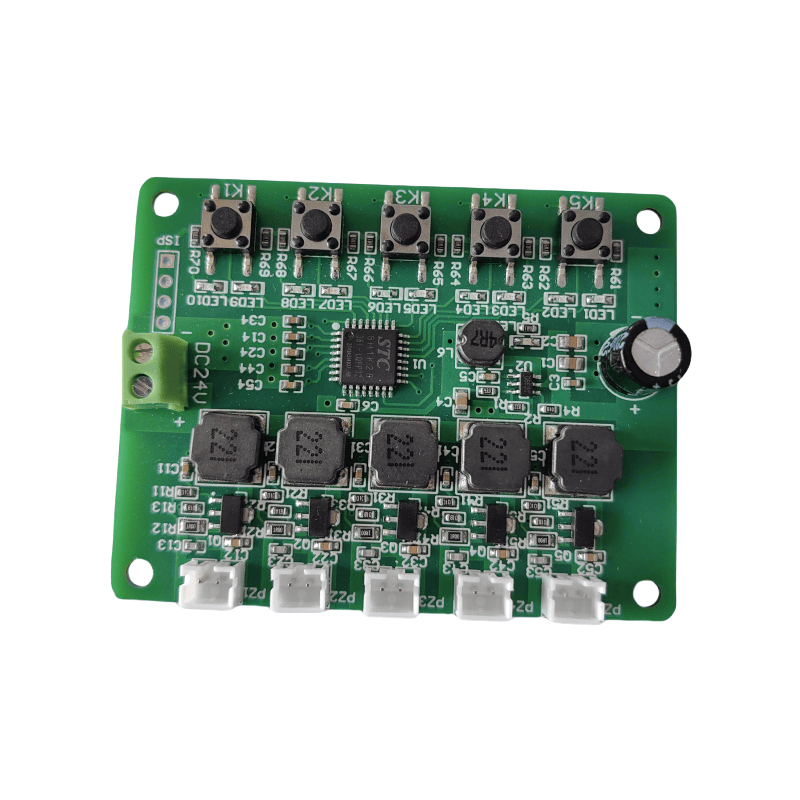

With 2.4 MHz becoming a mainstream operating frequency, high-frequency piezo atomizer discs require precise driving circuits and impedance matching. Enhanced stability improves ultra-fine mist generation, ensuring consistent particle distribution and low heat during prolonged operation.

Corrosion-Resistant Materials

To withstand various medication solutions and cleaning liquids, new piezo ceramic discs for nebulizers are adopting composite materials or surface treatment technologies. This ensures medical-grade piezo discs remain stable under high-humidity conditions.

The following table summarizes the common technical classifications of medical mesh piezo atomizer discs (example characteristics only, not linked to any specific company):

Common Technical Parameters of medical mesh piezo atomizer disc

| Technical Type | Frequency Range | Micro-Hole Structure | Features | Typical Applications |

|---|---|---|---|---|

| Low-Frequency Atomization | 1.7–2.0 MHz | Medium hole density | Low power consumption, suitable for basic atomization | Portable nebulizer, home care |

| Standard Medical Atomization | 2.4 MHz | High hole density | Uniform mist, high efficiency | Medical mesh nebulizer, respiratory therapy |

| High-Frequency Precision Atomization | ≥2.8 MHz | Ultra-high hole density | Finer mist, suitable for precise control | Aerosol generator, precision medical care |

Market Restructuring Drives Manufacturing and Supply Chain Evolution

As global demand for medical mesh piezo atomizer discs grows, related components such as ultrasonic mesh discs, mesh atomizer discs, and piezo atomizer discs are shifting from small-scale precision manufacturing to a more complete industrial supply chain.

Increased Component Integration

The popularity of portable devices has led manufacturers to offer more integrated components, such as mesh nebulizer atomizing discs with pre-installed electrodes or pre-assembled piezo ceramic atomizer disc modules. This reduces development costs for device manufacturers.

Standardization Trend

To meet regulatory requirements for safety and consistency, the dimensions, interfaces, and hole density of ultrasonic mesh discs are being gradually standardized, shortening the development cycle of medical inhalation therapy systems.

Higher Demand for Stable Supply Chains

Medical inhalation devices require long-term, reliable production. medical mesh piezo atomizer disc manufacturers are strengthening raw material management and quality control to improve overall industry reliability.

Expanding Applications: From Respiratory Therapy to Humidification and Skincare

Although initially used mainly for medical inhalation therapy, fine particle mesh discs are increasingly applied in light-care and consumer electronic devices.

Typical Applications Include:

- Portable medical mesh nebulizers

- Pediatric inhalation devices

- Facial steamers with integrated mesh atomizer plates

- Portable humidifiers with piezo atomizer discs

- Skincare mist devices

This cross-sector expansion increases demand for mesh nebulizer replacement discs and ultrasonic atomizer discs, accelerating technological iteration.

Conclusion: Core Components Drive Industry Advancement

The medical mesh piezo atomizer disc is not only a critical component of medical nebulizers but also a key driver of technological advancement. From micro-hole technology to high-frequency driving, from material design to energy efficiency, and from medical therapy to cross-sector applications, it promotes comprehensive upgrades of inhalation therapy devices.

With growing demand for finer, smarter, and more reliable nebulization, medical mesh piezo atomizer disc manufacturers will continue to innovate in process, materials, and system integration, enhancing the value of mesh atomizer discs, ultrasonic nebulizer discs, and mesh atomizer plates in medical and healthcare applications.

English

English 中文简体

中文简体