In the current landscape of indoor air regulation and environmental decoration, the ultrasonic mist maker has become a widely discussed device. It is not only applied in household humidity control but also widely used in greenhouses, decorative fountains, hydroponics, and aromatherapy. At the heart of this device lies the ultrasonic high-frequency piezo atomizer disc, a critical component that ensures stability and efficiency.

The Technical Logic of the Atomizer Disc

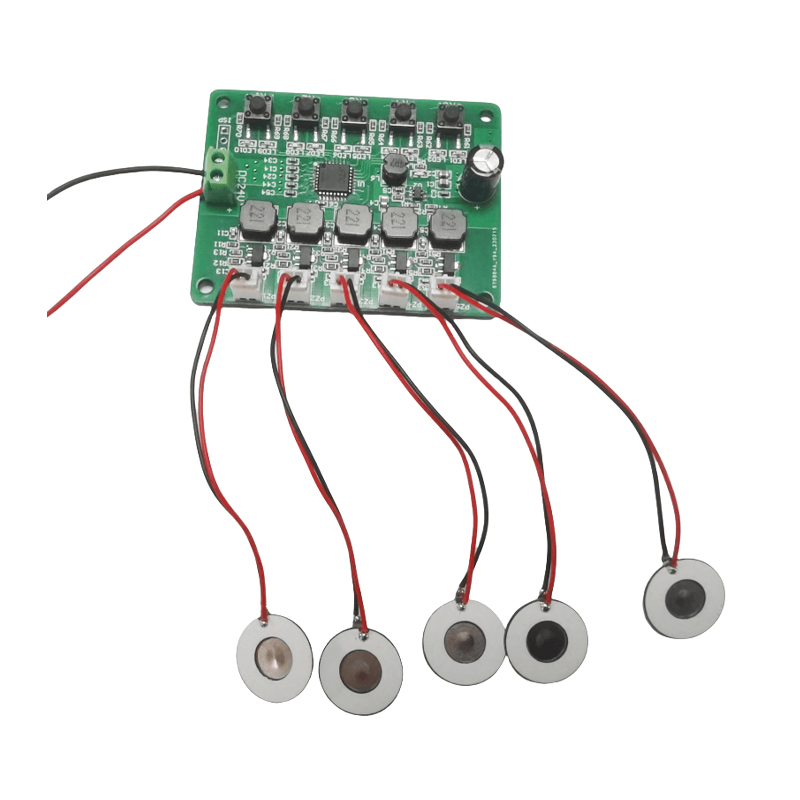

The ultrasonic mist maker operates based on high-frequency ultrasonic oscillation. The ultrasonic high-frequency piezo atomizer disc converts electrical energy into ultrasonic waves, driving liquid surfaces to produce ultra-fine mist particles. Unlike thermal evaporation, this process does not alter the chemical properties of the liquid, giving it clear advantages in energy efficiency, safety, and versatility.

Compared with other vaporization methods, the piezo atomizer disc provides higher efficiency and uniformity. The mist particles are smaller and more evenly distributed, allowing the ultrasonic mist maker to deliver a delicate and consistent performance in both air humidification and environmental decoration.

Segmentation of Application Scenarios

In practice, the ultrasonic mist maker has expanded beyond a single purpose, penetrating multiple fields. The following table outlines major application areas and their specific requirements for atomization:

| Application Scenario | Mist Feature Requirements | Role of Atomizer Disc |

|---|---|---|

| Household Humidification | Fine mist particles, silent operation | Ensures uniform mist output |

| Greenhouse & Agriculture | Continuous misting, large-scale coverage | Enhances spraying coverage |

| Hydroponic Systems | Increased air moisture, support for root growth | Provides stable and ongoing ultrasonic mist |

| Decorative Fountains | Aesthetic visual effects, light integration | Works with LED lights for dynamic mist views |

| Aromatherapy Diffusion | Preserves essential oil properties | High-frequency oscillation avoids heating |

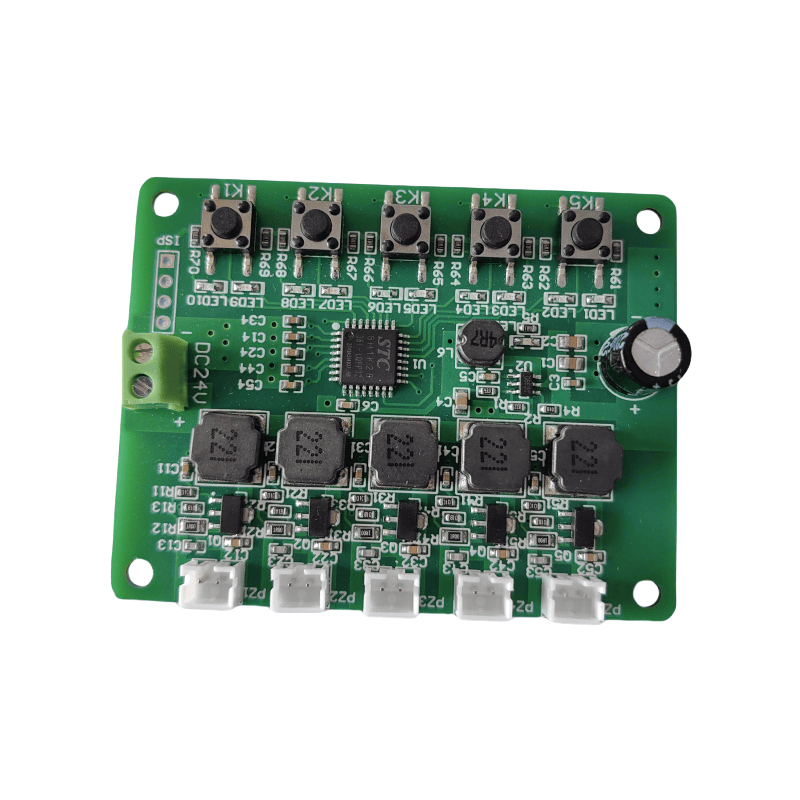

These differentiated demands are pushing the ultrasonic high-frequency piezo atomizer disc to evolve in multiple specifications and performance levels, enabling the ultrasonic mist maker to adapt to various environments.

Industry Value of High-Frequency Oscillation

As the applications of ultrasonic mist makers expand, the value of high-frequency oscillation technology becomes more prominent. Key benefits include:

Improved Atomization Precision: Higher frequencies produce smaller mist particles, which are quickly absorbed by the air.

Reduced Energy Consumption: Unlike thermal methods, ultrasonic misting avoids additional heating energy.

Material Compatibility: Works with pure water, essential oil solutions, and other liquids, broadening applications.

Extended Durability: Optimized piezo atomizer discs provide better wear and corrosion resistance.

The Keyword Aggregation Effect

In communication and market visibility, related terms around ultrasonic mist maker are forming an aggregation effect. Phrases such as ultrasonic fogger, ultrasonic humidifier mist maker, and ultrasonic water mist maker highlight different application areas. Meanwhile, long-tail keywords like ultrasonic mist maker with LED lights, ultrasonic mist maker for hydroponics, ultrasonic mist maker waterproof, and ultrasonic mist maker for greenhouse directly reflect niche market needs.

This multi-layered keyword structure showcases both the core features of the product and the user-driven demand for specific functionalities. For the industry, it signals clear directions for refining the design of ultrasonic high-frequency piezo atomizer discs.

Directions of Technological Advancement

From an industrial perspective, the evolution of ultrasonic high-frequency piezo atomizer disc technology is concentrated in several areas:

Frequency Optimization: Increasing oscillation frequencies to reduce mist particle size.

Structural Enhancements: Using composite materials or advanced processing to boost durability.

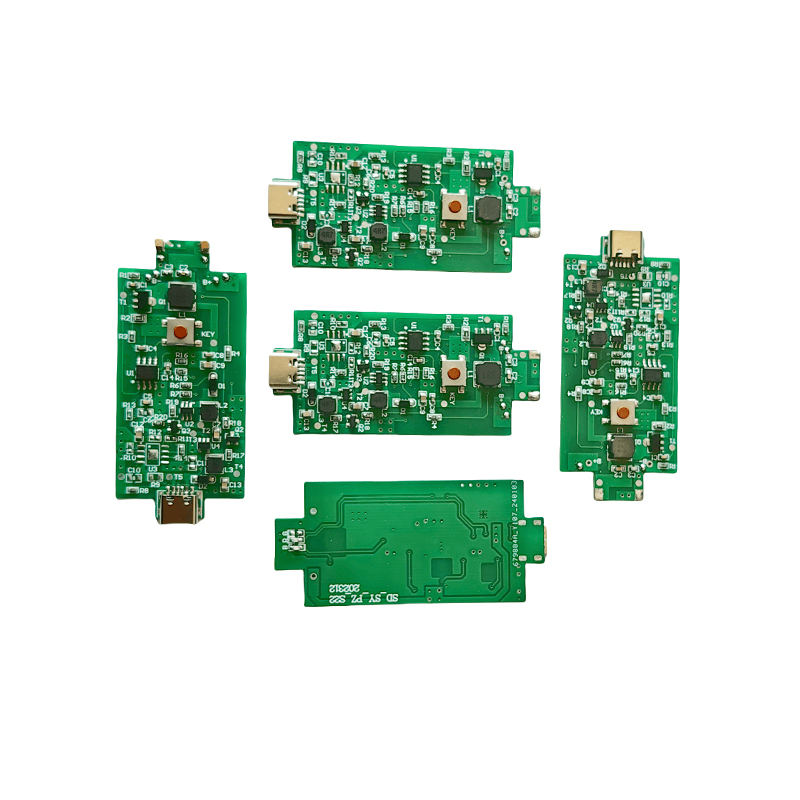

Modular Design: Enabling easy replacement and reducing maintenance costs.

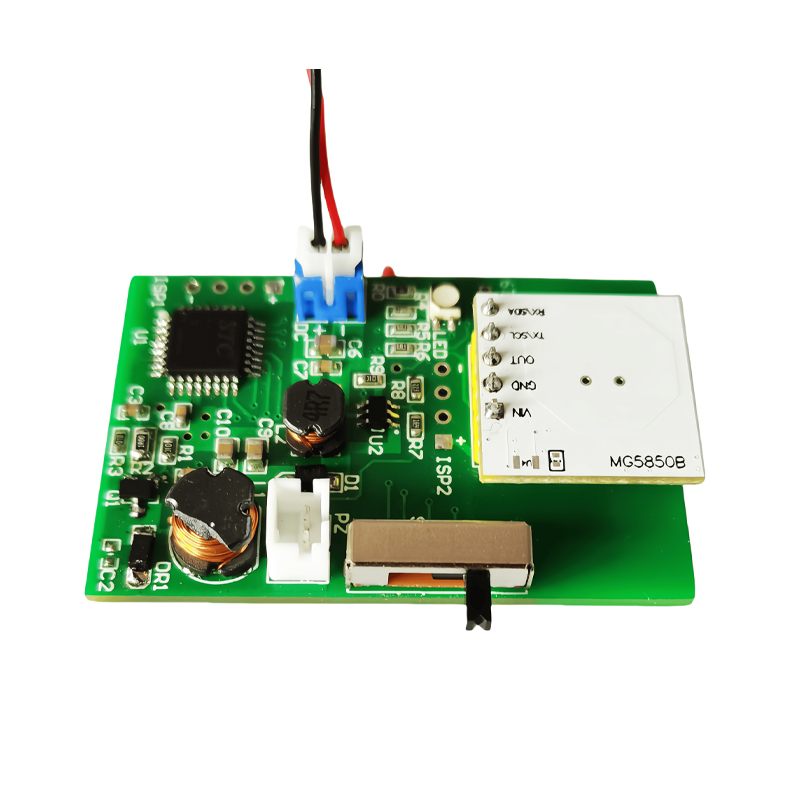

Multi-Functional Integration: Combining with LED lighting and sensors to meet decorative and smart-control demands.

This evolution is transforming the ultrasonic mist maker from a single-function humidification device into a multi-purpose tool for environmental creation.

Market Outlook and Industry Implications

With growing awareness of air quality and indoor comfort, demand for ultrasonic mist maker devices continues to rise. In greenhouses, aromatherapy, and decorative spraying, the performance of the ultrasonic high-frequency piezo atomizer disc directly determines product competitiveness.

Future industry trends will focus on:

Smart Control Integration: Pairing with sensors to automatically regulate mist intensity.

Energy Efficiency: Optimizing energy use to align with sustainability goals.

Cross-Field Applications: Extending beyond humidification to healthcare, aquaculture, and food preservation.

Maintenance Simplicity: Modular components to reduce replacement and repair complexity.

English

English 中文简体

中文简体