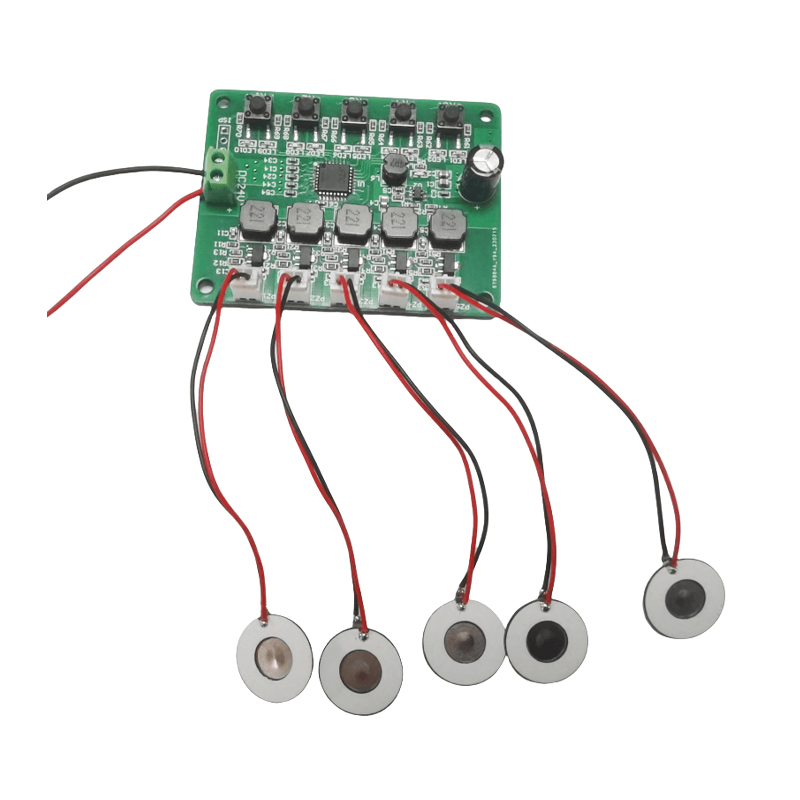

How Medical Piezoelectric Ceramic Discs Work: Principles, Structures, and Applications

The rapid advancement of medical electronics, diagnostic imaging, and minimally invasive treatment technologies has brought renewed attention to piezoelectric materials. Among them, the medical piezoelectric ceramic disc has become one of the most critical components in modern ultrasound systems, precision sensors, micro-actuators, nebulization devices, and wearable health-monitoring platforms. These compact and highly efficient piezoelectric elements enable medical devices to achieve higher resolution, lower power consumption, and better mechanical-electrical conversion performance.

Industry Landscape: Why Piezoelectric Ceramics Matter in Modern Medical Engineering

The global medical engineering sector is experiencing a transition from mechanical detection technologies to intelligent piezoelectric sensing. A medical piezoelectric ceramic disc stands at the center of this transformation due to its high responsiveness, stable frequency characteristics, and excellent energy-conversion efficiency.

Several factors drive the strong demand for these components:

Improved Ultrasound Imaging Performance

High-resolution ultrasound systems require transducers that offer:

- high sensitivity,

- stable resonance characteristics,

- accurate acoustic output,

- and consistent pulse-echo behavior.

Piezoelectric ceramic discs are ideal for such requirements.

Growth of Non-invasive and Minimally Invasive Diagnostics

Wearable health monitors, micro-ultrasound probes, soft-robotic medical tools, and implantable sensors rely heavily on compact piezoelectric elements to convert biological vibrations or electrical signals into measurable data.

Miniaturization of Medical Devices

Medical piezoelectric ceramic discs can be manufactured as thin as hundreds of micrometers while maintaining strong mechanical strength and excellent piezoelectric constants.

This enables device designers to achieve thinner, lighter, and more efficient medical systems.

Increased Demand for Acoustic-Electric Energy Conversion

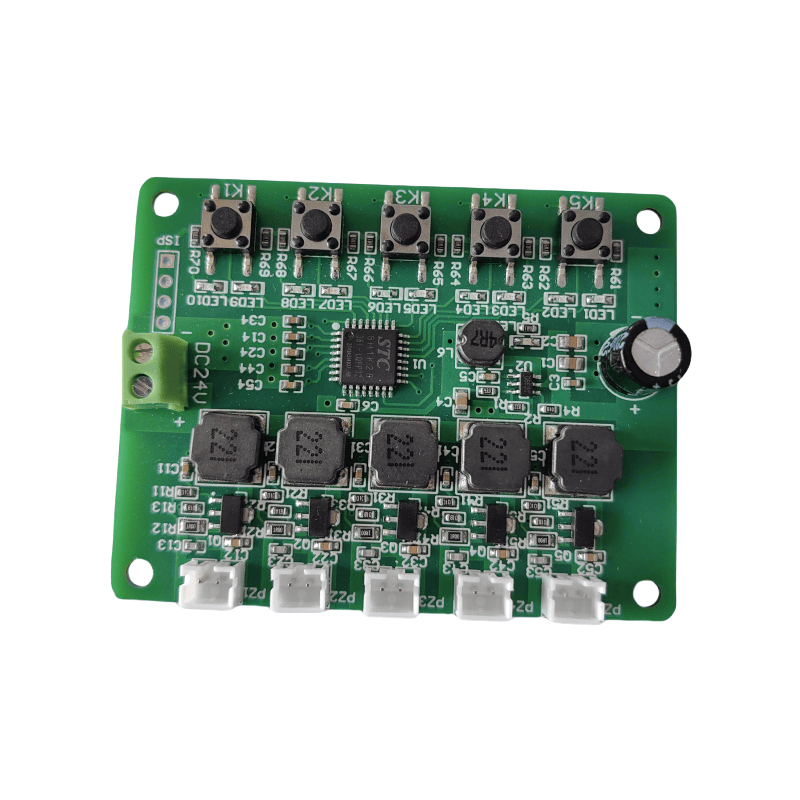

Piezoelectric ceramic discs play a major role in:

- ultrasonic nebulizers,

- therapeutic ultrasound emitters,

- microfluidic pumps,

- vibration-based actuators.

The combination of precision and low power consumption makes them essential in next-generation medical devices.

Working Principles of Medical Piezoelectric Ceramic Discs

The medical piezoelectric ceramic disc operates on the piezoelectric effect—a reversible interaction between electrical and mechanical energy. Two mechanisms define its functionality:

Direct Piezoelectric Effect (Sensing Mode)

When external pressure, sound waves, or mechanical vibration are applied to the disc, the material’s internal dipole moments shift, generating detectable charges at the electrodes.

Applications include:

- ultrasound echo reception,

- respiratory monitoring,

- cardiovascular vibration detection,

- pressure and micro-force sensors,

- wearable biosignals sensing.

Converse Piezoelectric Effect (Driving Mode)

When an electrical signal (usually AC) is applied to the disc, it expands and contracts periodically, creating mechanical vibration.

This effect enables:

- ultrasound transmission,

- nebulization and aerosol generation,

- microfluidic agitation,

- therapeutic ultrasound energy output,

- vibration-based actuation in miniature medical devices.

For best performance, the disc typically operates near its resonant frequency, maximizing mechanical displacement and minimizing energy loss.

Structural Design and Material Composition

The structure of a medical piezoelectric ceramic disc determines its acoustic response, electrical behavior, and long-term stability. Most discs share the following structural elements:

Structural Components

| Component | Function |

|---|---|

| Piezoelectric ceramic body (PZT-based) | Core structure that generates and receives electrical/mechanical energy |

| Electrode layers (Ag, Ni, Au, etc.) | Enable uniform electric-field distribution and efficient signal transmission |

| Backing / matching layers (optional) | Optimize acoustic impedance and improve transmission quality |

| Protective coating (optional) | Enhances resistance to humidity, chemicals, and wear |

Key Material Properties Influencing Performance

Several intrinsic material parameters determine the efficiency of a medical piezoelectric ceramic disc:

- Dielectric constant: affects sensitivity and impedance behavior

- Piezoelectric constants (d33, d31): relate to deformation amplitude and electrical output

- Mechanical quality factor (Qm): influences resonance stability

- Acoustic velocity and density: define bandwidth and efficiency

- Curie temperature: determines thermal reliability in medical environments

Below is a typical parameter range for industry-standard medical piezoelectric ceramic discs (non-brand, non-specific):

| Parameter | Typical Range | Description |

|---|---|---|

| Working frequency | 0.5–5 MHz | Higher frequencies used for imaging; lower for therapy |

| Thickness | 0.1–2.0 mm | Thinner discs generate higher resonance frequencies |

| Diameter | 3–50 mm | Chosen based on device design |

| Piezoelectric constant | 300–600 pC/N | Determines sensitivity and mechanical response |

These parameters can be tailored based on the requirements of the medical device.

Core Performance Advantages

A medical piezoelectric ceramic disc provides significant benefits across sensor and transducer applications:

High-frequency Responsiveness

The material maintains stable performance in MHz-level operations, allowing for:

- high-resolution imaging,

- advanced Doppler analyses,

- precise biosignal detection.

High Energy Conversion Efficiency

Compared to magnetic or purely mechanical actuators, piezoelectric ceramics deliver:

- lower energy loss,

- more stable output,

- higher sensitivity.

Miniaturization Capability

The disc’s thin profile enables it to fit into compact medical devices without compromising performance.

Long-term Durability

With proper electrode finishing and sealing, piezoelectric ceramics maintain performance for long periods under consistent vibration cycles.

High Customization Flexibility

Engineers can freely modify:

- geometry,

- electrode configuration,

- working frequency,

- material composition.

This makes the discs suitable for a wide range of precision medical applications.

Key Application Areas in Modern Medicine

Ultrasound Imaging Systems

The medical piezoelectric ceramic disc is the heart of every ultrasound transducer.

Its sensitivity and bandwidth affect:

- axial resolution,

- penetration depth,

- echo quality,

- noise control.

Therapeutic Ultrasound Devices

In physiotherapy, tissue stimulation, localized heating, and acoustic drug-delivery technologies, the disc generates controlled acoustic waves.

Nebulization and Microfluidic Aerosolization

Through rapid converse-piezoelectric vibration, liquid is atomized into fine particles, widely used in respiratory therapy and analytical microfluidics.

Cardiovascular and Respiratory Monitoring

The disc can detect subtle:

- thoracic movement,

- airflow vibrations,

- arterial pulsation,

- mechanical murmurs.

This makes it suitable for wearable health-monitoring devices.

Implantable Energy Harvesting Modules

The disc can convert body movement or organ vibrations into electrical energy, enabling low-power implantable systems.

Conclusion

The medical piezoelectric ceramic disc is a fundamental component shaping the evolution of modern medical technology.

With excellent energy conversion ability, mechanical robustness, high sensitivity, and wide customization possibilities, it plays an essential role across diagnostic imaging, therapy, microfluidics, and wearable monitoring.

FAQ

1. What material is a medical piezoelectric ceramic disc typically made of?

Most discs are composed of PZT-based piezoelectric ceramics, chosen for their strong piezoelectric constants and excellent structural stability.

2. Why are piezoelectric ceramic discs preferred in medical devices?

They provide high sensitivity, fast response times, low power consumption, and reliable frequency stability—advantages that other mechanical or magnetic materials cannot easily match.

3. How is the operating frequency of a piezoelectric ceramic disc determined?

It is primarily determined by the disc’s thickness and the material’s acoustic velocity. Thinner discs support higher resonance frequencies.

4. Can these discs be used in wearable healthcare devices?

Yes. Their compact size, low power requirement, and high sensitivity make them ideal for wearable and portable medical applications.

5. Do medical piezoelectric ceramic discs require special sealing?

In high-humidity or long-term medical environments, protective coatings or sealed housings are recommended to maintain operational stability.

English

English 中文简体

中文简体