Introduction

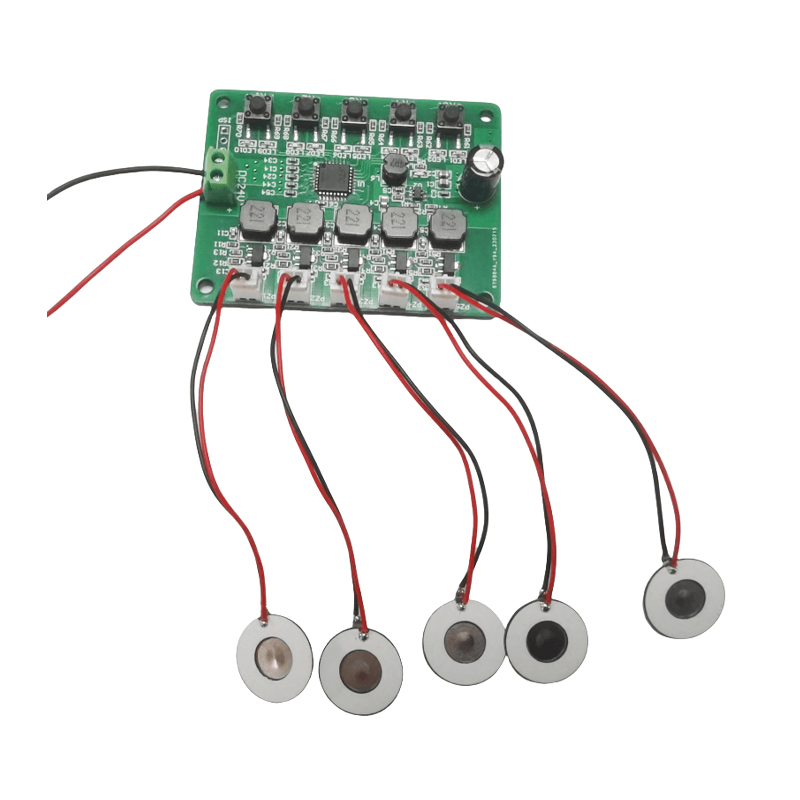

In modern medical devices, atomization technology has become increasingly important, particularly in respiratory therapy, drug delivery, and air sterilization. As a core component of atomization devices, the mesh atomizer disc directly determines atomization precision and efficiency. Choosing the right mesh atomizer disc not only affects device performance but also influences patient experience and treatment outcomes.

Key Features of a Mesh Atomizer Disc

A mesh atomizer disc, also called an atomizer mesh plate, uses ultrasonic or piezoelectric principles to transform liquid into fine droplets through a micro-perforated mesh. Its main characteristics include pore size, material type, durability, and atomization efficiency.

Pore Size and Atomization Precision

Pore size directly affects the diameter of atomized particles, which is critical in medical applications. For example, drug inhalation devices require particle diameters between 1–5 microns to ensure medication reaches the deep lungs. Too large pores produce coarse droplets with lower inhalation efficiency, while too small pores may clog or reduce atomization rate.

| Pore Size (microns) | Applicable Medical Device | Atomization Effect | Notes |

|---|---|---|---|

| 1-3 | Respiratory drug nebulizers | Fine particles, deep lung delivery | Preferred for high-precision medical devices |

| 3-5 | Air sterilizers | Medium particles, wide coverage | Common for indoor air atomization |

| 5-10 | Auxiliary humidifiers | Coarse particles, fast humidification | Non-drug atomization usage |

Material Type

Mesh atomizer discs are commonly made from stainless steel, titanium alloy, or ceramic. In medical applications, materials must be corrosion-resistant, high-temperature resistant, easy to clean, and free from harmful substances during long-term use. Different materials affect atomization efficiency and durability:

| Material | Advantages | Disadvantages | Medical Suitability |

|---|---|---|---|

| Stainless Steel | Corrosion-resistant, easy to clean | High hardness, precision pore requirements | High |

| Titanium Alloy | Lightweight, corrosion and heat resistant | High cost | High |

| Ceramic | Uniform droplets, chemically stable | Fragile | Medium |

Special Requirements for Medical Applications

In medical scenarios, mesh atomizer discs must not only ensure efficient atomization but also meet strict hygiene and safety standards. Key considerations include:

Particle size precision: Drug delivery devices require stable particle diameters for effective respiratory absorption.

Corrosion resistance and cleanability: Medication solutions may be acidic, alkaline, or viscous; the mesh must resist corrosion and be easily sterilized.

Stable power consumption and durability: Medical devices often operate continuously; the disc must provide low-power, long-life performance.

Noise control: Ultrasonic or piezoelectric drive should maintain low noise for patient comfort.

Particle Stability and Treatment Efficiency

In respiratory therapy, particle size determines deposition location and absorption efficiency. Medical mesh atomizer discs must ensure stable particle sizes within the 1–5 micron range.

| Particle Diameter | Deposition Location | Treatment Effect |

|---|---|---|

| <1 micron | Terminal bronchioles | Minimal deposition, incomplete absorption |

| 1–5 microns | Alveoli | Even deposition, optimal absorption |

| >5 microns | Upper airway | Concentrated deposition, lower treatment efficiency |

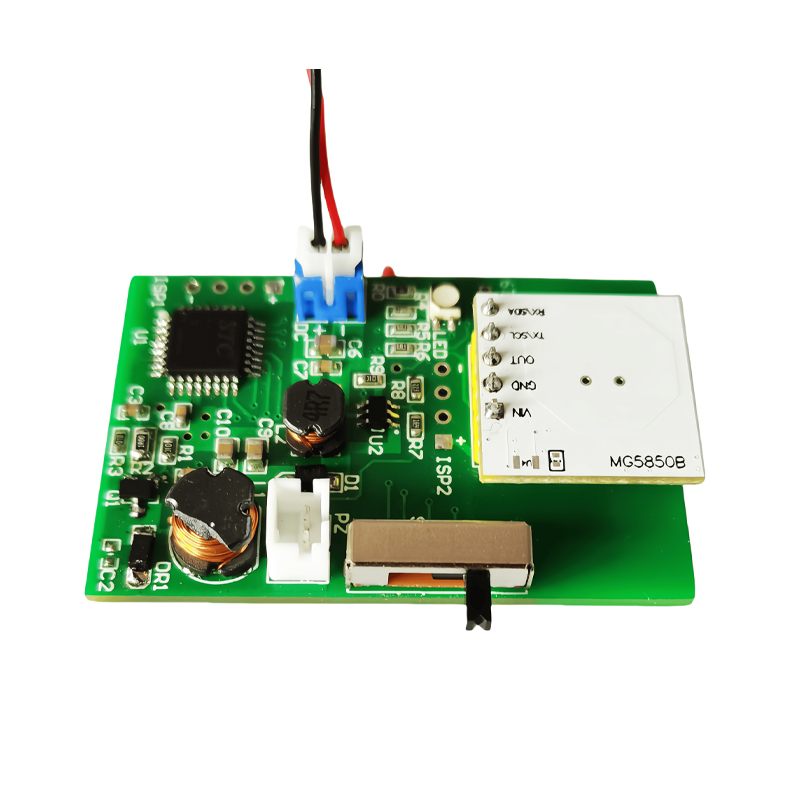

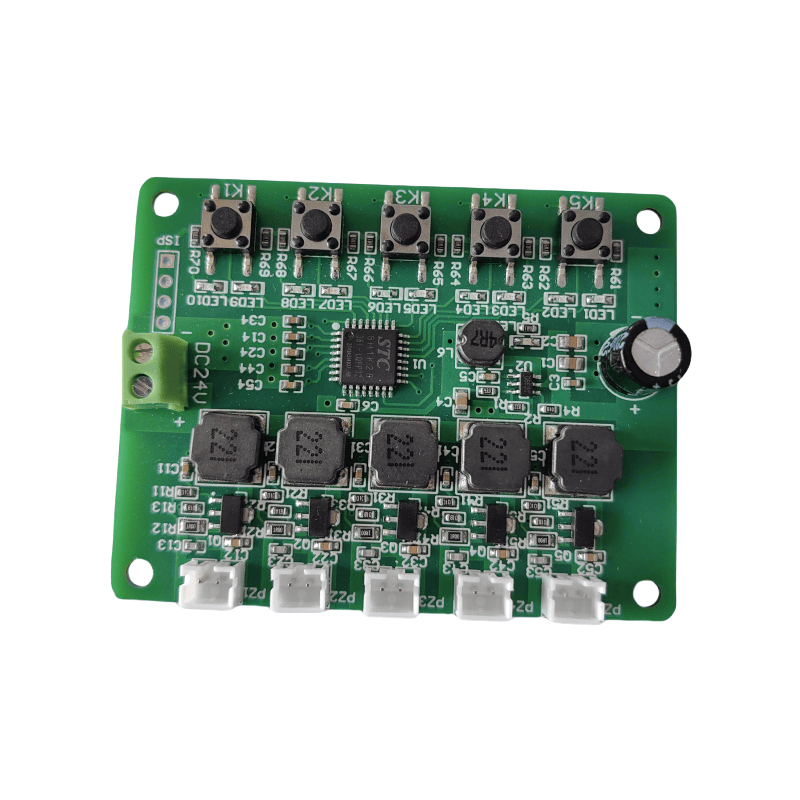

Power and Atomization Efficiency

The driving power of a mesh atomizer disc significantly affects atomization efficiency. Medical devices require stable atomization rates; excessive power may evaporate liquid too quickly and waste medication, while insufficient power results in incomplete atomization, reducing treatment efficacy.

| Driving Power | Atomization Rate | Recommendation |

|---|---|---|

| Low | Moderate | Suitable for low-concentration drugs or continuous atomization |

| Medium | High | Preferred for standard medical atomizers |

| High | Fast | Suitable for rapid atomization scenarios |

How to Choose the Right Mesh Atomizer Disc

When selecting a mesh atomizer disc, consider the following:

Choose pore size based on application: 1–5 microns for respiratory therapy, larger pores for air humidification or sterilization.

Select material for durability and safety: Stainless steel or titanium alloy are preferred for medical use.

Match power and device requirements: Ensure stable atomization rate and particle size.

Consider cleaning and sterilization: Removable or easy-to-clean designs ensure long-term safety.

Choose reliable mesh atomizer disc manufacturers: Ensure product quality meets medical standards.

Medical Device Mesh Atomizer Disc Specifications

| Product Type | Pore Size (microns) | Material | Power Requirement | Applicable Device Type |

|---|---|---|---|---|

| Respiratory drug nebulizer disc | 1–3 | Stainless steel | Medium | Drug inhalation devices |

| Hospital indoor air sterilizer disc | 3–5 | Titanium alloy | Medium | Air sterilization devices |

| Home auxiliary humidifier disc | 5–10 | Stainless steel | Low | Hospital humidifiers, lab use |

Trends in Medical Mesh Atomizer Disc Development

With advances in medical atomization technology, mesh atomizer discs are showing several trends:

High-precision micro-pore design: Ensures uniform droplet distribution and improved drug deposition.

Lightweight and durable: Titanium alloy or composite materials reduce weight and extend lifespan.

Energy-efficient and low-noise: Low-power drive and silent operation enhance patient experience.

Multi-functional designs: Some discs incorporate filtration or antibacterial features for integrated medical solutions.

Conclusion

Selecting the right mesh atomizer disc is critical to improving medical atomization device performance. By considering pore size, material, power compatibility, and cleaning maintenance, devices can achieve optimal particle precision, stability, and safety. Collaborating with reliable mesh atomizer disc manufacturers ensures high-quality products that meet medical standards. As medical atomization technology evolves, high-precision, energy-efficient, and durable mesh atomizer discs will remain essential components in healthcare equipment.

English

English 中文简体

中文简体