Industrial application of lead-free piezoelectric materials in ultrasonic atomizer: a double breakthrough in environmental protection and performance

Material Revolution driven by environmental regulations

In recent years, regulations such as the EU RoHS Directive and China's "Regulations on the Restriction of Hazardous Substances in Electrical and Electronic Products" have increasingly restricted lead electronic components, which has directly prompted manufacturers of Ultrasonic Mist Maker to seek more environmentally friendly alternatives. Although traditional PZT (lead zirconium titanate) piezoelectric ceramics have excellent performance, their lead content is as high as 60%, and there is a risk of environmental pollution during production, use and waste stages. The breakthrough in research and development of lead-free piezoelectric materials provides the industry with an alternative option that meets environmental protection requirements and is of considerable performance.

Market research shows that the global lead-free piezoelectric Ultrasonic Mist Maker market size has reached US$380 million in 2023, with an annual growth rate of more than 25%, far higher than the 5% growth rate of traditional products. It is particularly worth noting that in the field of medical and maternal and infant nebulizers, the market penetration rate of lead-free products has exceeded 45%, reflecting consumers' high favoritism for health and safety products.

Technical breakthroughs in lead-free piezoelectric materials

The research and development of lead-free piezoelectric materials has moved from laboratory to industrialization, and the most representative of them are two major material systems: potassium sodium niobate (KNN) and barium titanate (BT)-based. By precisely controlling the crystal structure and doping modification, the piezoelectric constant d33 of the newly developed KNN-based material has reached 450pC/N, close to the level of traditional PZT ceramics, and fully meets the performance requirements of Ultrasonic Mist Maker for high-frequency vibration.

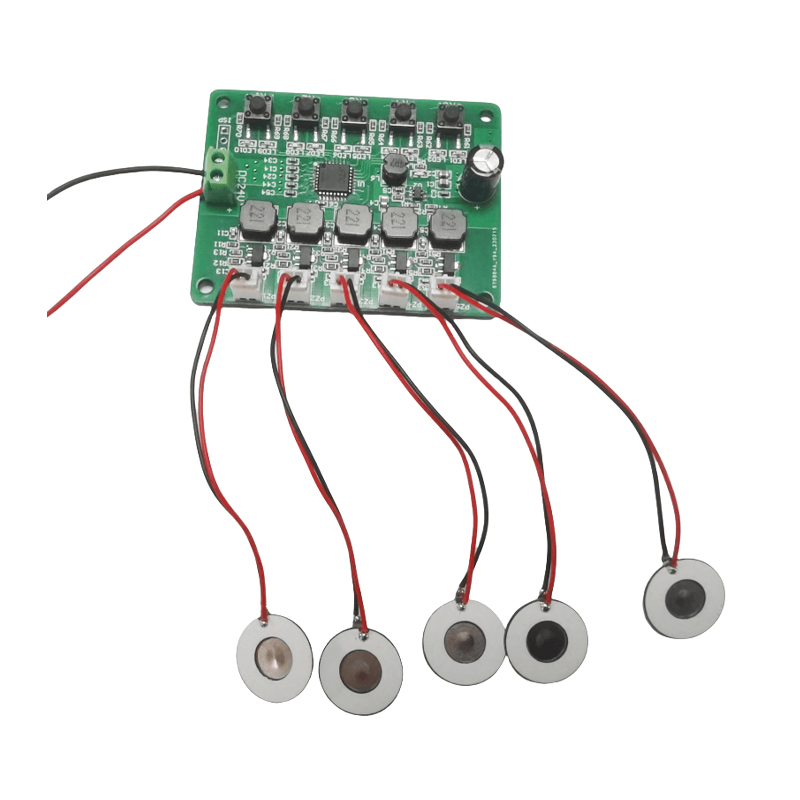

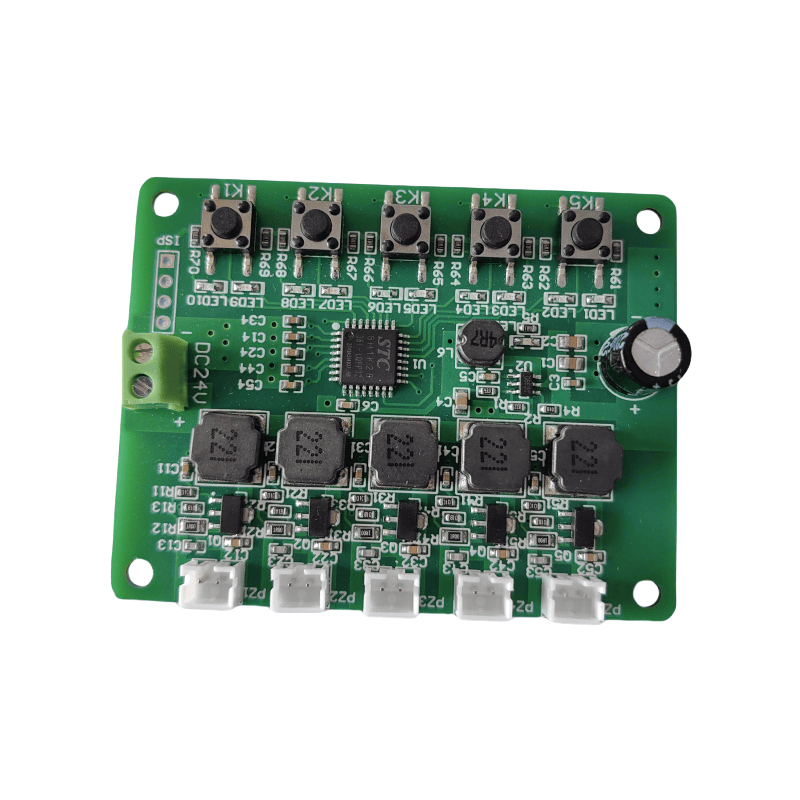

In terms of material technology, breakthroughs in low-temperature co-fired technology are particularly critical. This allows lead-free piezoelectric materials to be sintered synchronously with electrode materials, solving the problem of performance deterioration caused by traditional high-temperature processes. The laminated lead-free piezoelectric component developed by a leading manufacturer has atomization efficiency of 3.2ml/min at 1.7MHz operating frequency, which is 15% higher than traditional lead-containing components, and energy consumption is reduced by 20%.

Comprehensive improvement of atomizer performance

The application of lead-free piezoelectric materials has enabled the Ultrasonic Mist Maker to achieve unprecedented performance improvements. The new material has a higher electromechanical coupling coefficient and an energy conversion efficiency of more than 85%, which makes the atomized particles more uniform and delicate, and the average particle size can be controlled in the range of 1-3 microns, which is especially suitable for medical inhalation and precision humidification applications.

Lead-free materials show obvious advantages in terms of reliability. Test data show that under the same operating conditions, the lifespan of lead-free piezoelectric components is 30-40% longer than that of traditional PZT components, mainly due to their higher anti-aging performance and heat cycling resistance. A certain brand uses lead-free medical atomizer, and its continuous working life has exceeded 8,000 hours, greatly reducing the cost of equipment maintenance.

Key Challenges of Industrial Application

Despite the obvious advantages, the comprehensive promotion of lead-free piezoelectric materials in the Ultrasonic Mist Maker still faces several challenges. Material cost is the main obstacle at present, and the price of high-performance lead-free piezoelectric ceramics is still 1.5-2 times that of traditional PZT. However, with the advancement of large-scale production, this gap is narrowing rapidly, and costs are expected to remain basically the same in 2025.

Adaptation of production processes is another major challenge. Lead-free materials have stricter requirements for sintering temperature and atmosphere control, and manufacturers need to renovate existing production lines. Leading companies have developed special sintering equipment, which increases the product yield rate to more than 95% through precise temperature field control and atmosphere adjustment, clearing obstacles for large-scale industrialization.

Innovative applications in the medical and home fields

In the medical and health field, lead-freeUltrasonic Mist Maker is opening up new application scenarios. Respiratory therapy equipment adopts lead-free materials with better biocompatible properties, avoiding the risk of lead ions precipitation; the portable atomizer benefits from the low power consumption characteristics of the material, and the battery life time is extended by more than 50%; while the precise drug delivery system utilizes the high-frequency stability of the material to achieve accurate control of the size of the drug particles.

Home applications are also full of highlights. After the high-end humidifier uses lead-free piezoelectric components, the working noise is reduced to below 30 decibels; the aromatherapy machine achieves a more delicate atomization effect through material improvement, and the utilization rate of essential oils is increased by 40%; while the intelligent atomization system for agriculture has greatly extended its service life in humid environments due to the corrosion resistance of the materials.

Sustainable Development and Circular Economy

The promotion of lead-free piezoelectric materials has significantly improved the sustainability of the Ultrasonic Mist Maker industry. From the perspective of the production link, the lead-free process reduces the discharge of heavy metal wastewater by more than 90%; the risk of lead element release is eliminated during the use stage; during scrapping and recycling, the materials can be safely crushed and used for building materials, realizing a closed-loop cycle.

Carbon footprint analysis shows that the carbon emissions of atomizer products using lead-free piezoelectric components are 35% lower than those of traditional products throughout the life cycle. Some leading manufacturers have begun using renewable energy for material sintering to further reduce environmental loads, and these efforts have enabled the product to obtain authoritative environmental certifications such as EPEAT and Blue Angel.

Future development trends and market opportunities

Looking ahead, lead-free piezoelectricUltrasonic Mist Maker will develop in three directions: adaptive smart materials can automatically adjust vibration parameters according to the properties of the liquid; self-energy systems use piezoelectric effects to recover environmental energy; modular design allows core components to be replaced individually, greatly extending the service life of the product.

English

English 中文简体

中文简体