Material Selection and Manufacturing Processes for Medical-Grade Piezoelectric Ceramic Discs

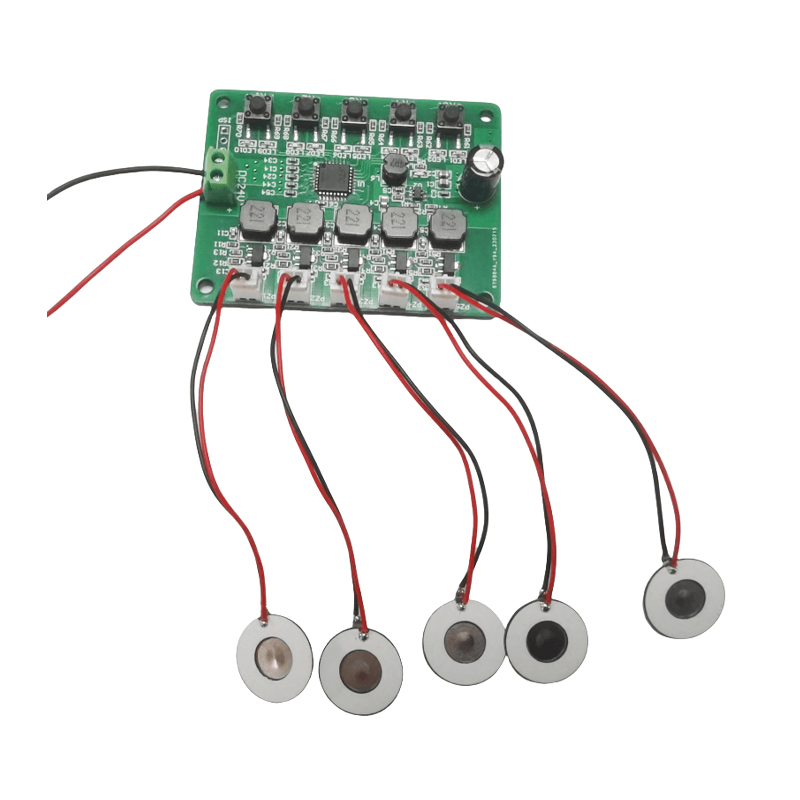

As global medical technologies progress toward higher precision, miniaturization, and intelligent diagnostics, the medical piezoelectric ceramic disc has become a critical functional component across ultrasonic imaging systems, high-accuracy medical sensors, diagnostic probes, micro-actuators, and advanced therapeutic devices. The performance, stability, and reliability of these medical-grade piezoelectric ceramics directly influence imaging clarity, sensing accuracy, device lifespan, and procedural safety. Consequently, material selection strategies and manufacturing processes for these discs have gained heightened industry attention.

Performance Requirements and Industry Background

A medical piezoelectric ceramic disc is a functional ceramic element capable of converting mechanical energy into electrical energy and vice versa. In the medical field, it enables acoustic transmission and reception, pressure sensing, micro-vibration actuation, and energy coupling. As medical systems demand higher resolution, faster response, and greater long-term durability, medical-grade piezoelectric ceramics must achieve:

- High and stable piezoelectric coefficients

- Low dielectric loss and strong insulation properties

- Microstructural stability under continuous operation

- Reliable multi-frequency response capability

- Biocompatibility for certain clinical environments

- Consistent output performance during ultrasonic and high-frequency operations

These requirements make material formulation, structural control, and precision manufacturing essential determinants of product integrity and device performance.

Material Systems and Principles of Selection

The majority of medical piezoelectric ceramics still rely on lead zirconate titanate (PZT)-based perovskite materials due to their superior electro-mechanical coupling characteristics. However, interest in lead-free piezoelectric materials is growing under evolving environmental and regulatory expectations.

Common Material Systems and Characteristics

| Material System | Structural Features | Performance Advantages | Industry Trends |

|---|---|---|---|

| PZT-based ceramics | Perovskite structure | High piezoelectric constants; mature processing | Mainstream choice for ultrasonic imaging and sensor applications |

| Lead-free perovskites (e.g., KNN) | Potassium-sodium niobate structure | Environment-friendly; good thermal stability | Increasing attention in sustainable healthcare |

| Bismuth-layered ceramics | Layered crystal structure | Strong fatigue resistance; structural stability | Explored for high-frequency micro-devices |

| Tungsten-bronze ceramics | Tunnel-like framework | Favorable high-frequency reliability | Applied in micro-actuation and precision sensors |

Fundamental Material Selection Principles

-

Stability as a priority

Medical devices operate continuously for long periods; even minor material relaxation or acoustic loss may degrade performance. -

High repeatability and batch consistency

Many medical probes require multi-element assemblies, making uniform material properties essential. -

Process compatibility

The ceramic must tolerate ultra-thin grinding, laser dicing, and precise polarization without micro-cracking. -

Conformance to regulatory standards

Certain medical environments or sustainable-development requirements favor lead-free systems, provided performance remains sufficient.

Manufacturing Processes for Medical-Grade Piezoelectric Ceramic Discs

The production process for the medical piezoelectric ceramic disc involves refined control over powder synthesis, forming, sintering, slicing, polishing, electrode deposition, and polarization. Each step can significantly influence acoustic features, dielectric stability, and frequency consistency.

Powder Preparation

High-purity powder is the foundation for achieving optimal piezoelectric behavior. Common preparation methods include solid-state synthesis, chemical co-precipitation, and sol-gel processing.

Key control objectives:

- Narrow particle size distribution

- High phase purity

- Prevention of impurity-induced defects or porosity

Forming Technology

Forming methods include dry pressing, isostatic pressing, and tape casting. For thin and miniaturized medical piezoelectric ceramic discs, isostatic pressing often provides superior density uniformity.

Priorities during forming:

- Uniform green-body density

- Prevention of delamination

- Tight dimensional control

Sintering and Microstructural Tuning

Sintering determines ceramic densification, grain structure, and domain mobility. Medical-grade requirements typically include:

- Densification close to theoretical density

- Absence of abnormal grain growth

- Controlled grain size for frequency specificity

Sintering temperature profiles, atmosphere control, and hold times must be precisely managed to achieve such outcomes.

Slicing and Precision Grinding

The thickness of the ceramic directly defines the resonant frequency. Medical applications often demand micron-level thickness accuracy to ensure consistent acoustic output.

Common processing steps:

- Diamond-wheel grinding

- Fine polishing to reduce surface roughness

- Laser dicing to minimize mechanical stress

Electrode Deposition

Electrode layers must provide reliable conductivity without affecting mechanical integrity. Thin metal or alloy films are typically applied through sputtering or evaporation.

Critical factors include:

- Uniform electrode thickness

- Strong adhesion

- No induced surface stress or micro-defects

Polarization

Polarization activates the piezoelectric properties by aligning dipole domains under high electric fields. The process requires strict control of:

- Electric field intensity

- Temperature

- Duration

Improper polarization can lead to unstable piezoelectric coefficients, frequency drift, or reduced long-term reliability.

Inspection and Quality Standards

Only ceramic discs that pass rigorous inspection can be integrated into medical systems. Testing evaluates both functional performance and structural reliability.

Key Testing Items

| Test Item | Purpose | Evaluation Parameters |

|---|---|---|

| Dielectric measurement | Ensures stable signal response | Dielectric constant, dielectric loss |

| Piezoelectric performance | Validates energy conversion efficiency | d33, coupling factor, resonance frequency |

| Acoustic testing | Measures ultrasonic behaviors | Acoustic impedance, bandwidth |

| Mechanical reliability | Ensures structural endurance | Flexural strength, fatigue resistance |

| Environmental stability | Assesses durability under harsh conditions | Heat-humidity cycling, aging tests |

Industry Quality Control Principles

-

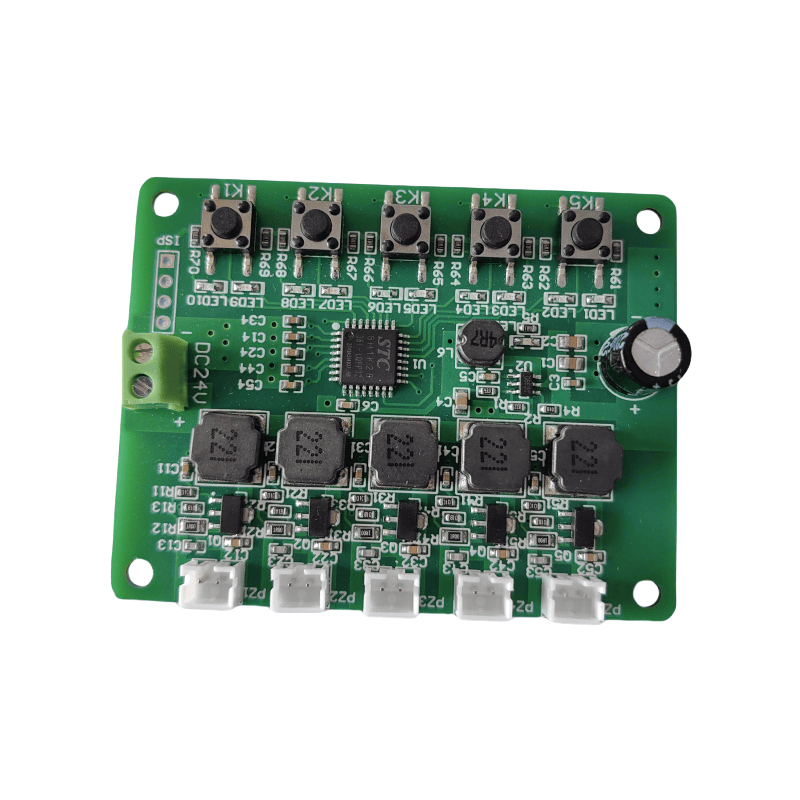

Strict batch uniformity

Multi-element probe assemblies require matching electrical and acoustic parameters across many discs. -

Minimization of defects

Micro-cracks, voids, or edge chipping can compromise device safety and lifespan. -

Compliance with medical reliability protocols

Long-term drift, humidity tolerance, and thermal stability must be validated for clinical environments.

Trends in Medical Applications

The medical piezoelectric ceramic disc is expanding into broader sectors as medical equipment evolves toward higher resolution, portability, and intelligent sensing.

High-Resolution Ultrasonic Imaging

Higher-frequency transducers depend heavily on:

- Ultra-thin ceramic discs

- Optimized grain structures

- Broad-bandwidth electromechanical conversion

This enables enhanced image clarity for diagnostic ultrasound and high-frequency micro-imaging.

Wearable and Implantable Medical Devices

Flexible piezoelectric sensors and micro-actuators support:

- Long-term vital-sign monitoring

- Bio-signal capturing

- Smart rehabilitation technologies

Miniaturized ceramic discs with low loss and high stability have become essential in these emerging systems.

Minimally Invasive Surgical Devices

Instruments such as micro-pumps, ultrasonic surgical tools, and precision positioners rely on:

- Stable high-power actuation

- Robust thermal endurance

- Precise vibration control

This segment is driving demand for highly reliable micro-scale ceramic components.

Growth of Lead-Free Piezoelectric Ceramics

With sustainability concerns increasing, lead-free materials are gaining traction for:

- Biodegradable medical tools

- Environment-friendly medical electronics

- Temperature-resilient sensor applications

Although performance still lags behind PZT in certain metrics, R&D activity is accelerating.

FAQ

1. What is a medical piezoelectric ceramic disc?

It is a functional ceramic component capable of converting electrical and mechanical energy, widely used in ultrasonic imaging, precision sensors, diagnostic probes, and micro-actuators.

2. How does medical-grade piezoelectric ceramic differ from industrial ceramics?

Medical ceramics demand far higher precision, reliability, consistency, and stability, along with stricter quality and environmental controls.

3. How does thickness affect the working frequency of a piezoelectric ceramic disc?

The resonant frequency is inversely proportional to disc thickness; thinner discs support higher-frequency ultrasonic applications.

4. Can medical devices use lead-free piezoelectric ceramic materials?

Yes, but suitability depends on performance requirements, especially for high-frequency or high-energy applications where traditional PZT still offers superior output.

5. What factors most influence the final performance of a medical piezoelectric ceramic disc?

Key factors include powder purity, sintering quality, thickness precision, electrode adhesion, and polarization parameters.

English

English 中文简体

中文简体