Material Synergy Mechanism of Stainless Steel Lead Free Medical Mesh Nebulizer Tablets

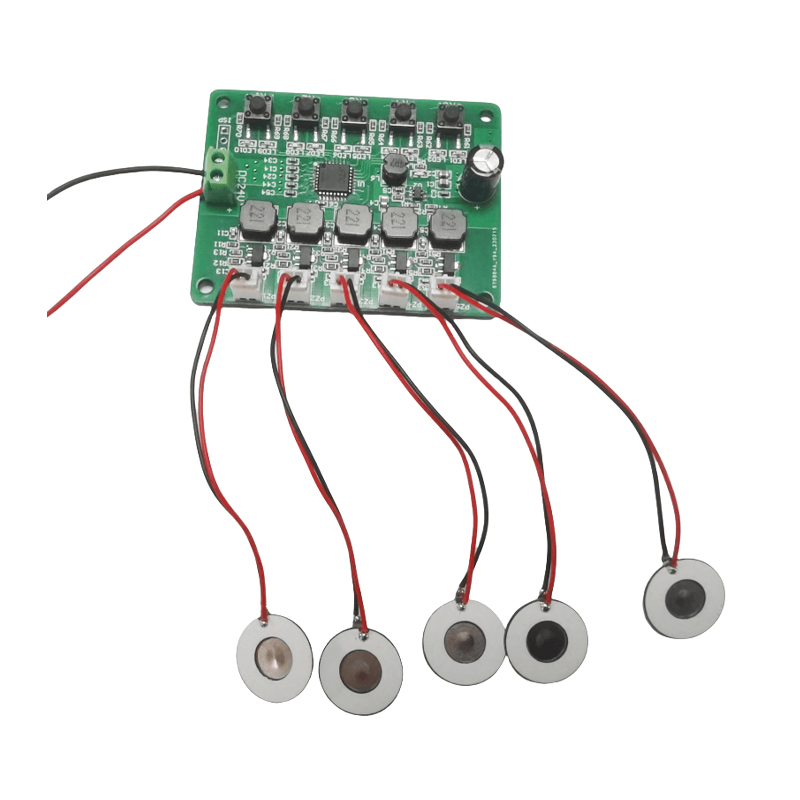

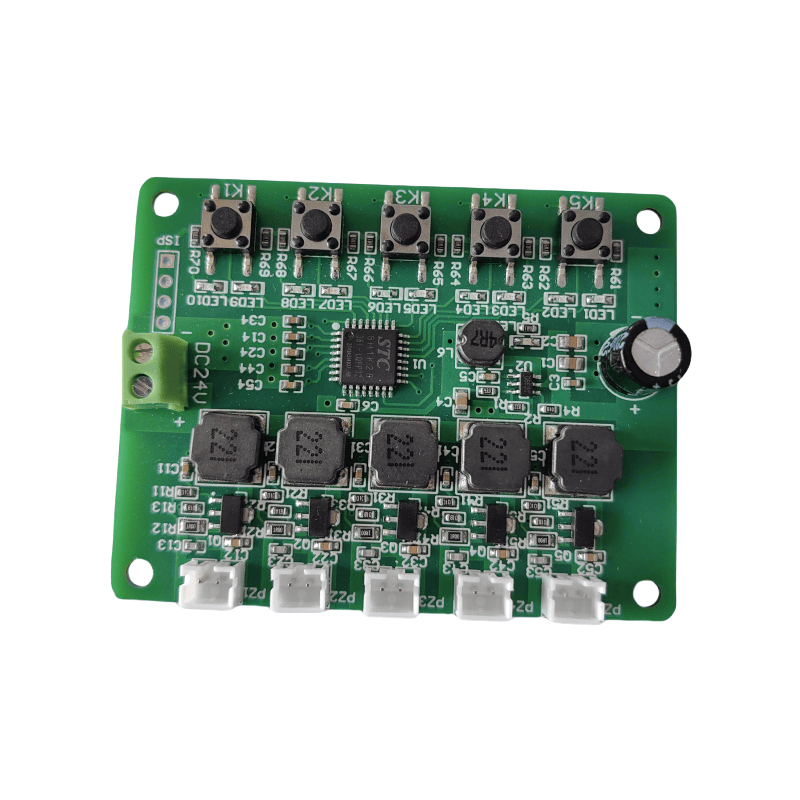

The efficient operation of Stainless Steel Lead Free Medical Mesh Nebulizer Tablets depends on the special physical properties of stainless steel mesh. The mesh made of high-strength 316L stainless steel, with its excellent mechanical properties, becomes a stable carrier for vibration energy transmission. This material not only has high strength and can maintain structural integrity under high-frequency vibration environment, but also has good mechanical conductivity, ensuring that the high-frequency vibration generated by lead-free piezoelectric ceramics can be quickly and evenly transmitted to every part of the mesh. When the lead-free piezoelectric ceramics produce periodic deformation under the drive of electric energy, the released vibration energy spreads rapidly along the lattice structure of the stainless steel mesh in the form of mechanical waves, providing a stable energy basis for the subsequent atomization of the liquid medicine.

Breakthrough of the surface tension of the liquid medicine and the start of atomization

When high-frequency vibration acts on the stainless steel mesh, the liquid medicine attached to the surface of the mesh starts the atomization process due to the change in surface tension. Surface tension, as the force generated by the mutual attraction between molecules on the surface of the liquid, maintains the liquid integrity of the liquid medicine under normal conditions. When the stainless steel mesh vibrates at high frequency, the external force on the drug molecules breaks the balance of surface tension. The kinetic energy generated by the vibration is transferred to the drug molecules, allowing them to obtain enough energy to overcome the surface tension constraints. Under this energy impact, the drug moves toward the micron-sized mesh at an extremely high speed, and the original continuous drug form begins to change, creating conditions for atomization and dispersion.

Precision mold for drug constraint and cutting

The micron-sized mesh is the key structure for stainless steel lead free medical mesh nebulizer tablets to achieve precise atomization. These meshes are specially optimized and designed, and their size and shape are like precision molds, which form precise constraints and cutting on the drug. When the high-speed moving drug reaches the mesh, the friction and constraint force generated by the mesh wall on the drug restricts the flow path of the drug and forces the drug to deform when passing through the mesh. The geometric shape of the mesh quickly cuts and disperses the drug at the moment it passes through, dividing the large volume of drug into countless tiny droplets. This precise constraint and cutting process allows the drug liquid to be efficiently dispersed into tiny and uniform aerosol particles, providing high-quality drug carriers for atomization therapy.

Double improvement of atomization performance and therapeutic effect

The high strength and good conductivity of the stainless steel mesh, the breakthrough of high-frequency vibration on the surface tension of the drug liquid, and the precise constraint cutting of the mesh structure, the three work together to significantly improve the overall performance of the atomizer. Efficient energy conduction and stable vibration output ensure that the drug liquid can be fully atomized in a short time, greatly improving the atomization efficiency. The aerosol particles generated by the precise mesh processing are optimized in particle size distribution, and their size is more in line with the physiological characteristics of the human respiratory tract. Smaller and uniform particles can smoothly pass through the layers of filtration in the respiratory tract, penetrate deep into the lung tissue, increase the contact area between the drug and the lesion, and improve the drug deposition efficiency, thereby enhancing the clinical treatment effect and bringing a better treatment experience to patients with respiratory diseases.

English

English 中文简体

中文简体