Introduction to Mesh Nebulizer Chips

The mesh nebulizer chip has emerged as a groundbreaking component in modern respiratory therapy devices. As the core element of mesh nebulizers, this micro-engineered component enables efficient medication delivery by converting liquid medicine into a fine mist. The precision and reliability of mesh nebulizer chips have transformed treatments for asthma, COPD, and other respiratory conditions, offering faster absorption and improved patient outcomes compared to traditional jet nebulizers.

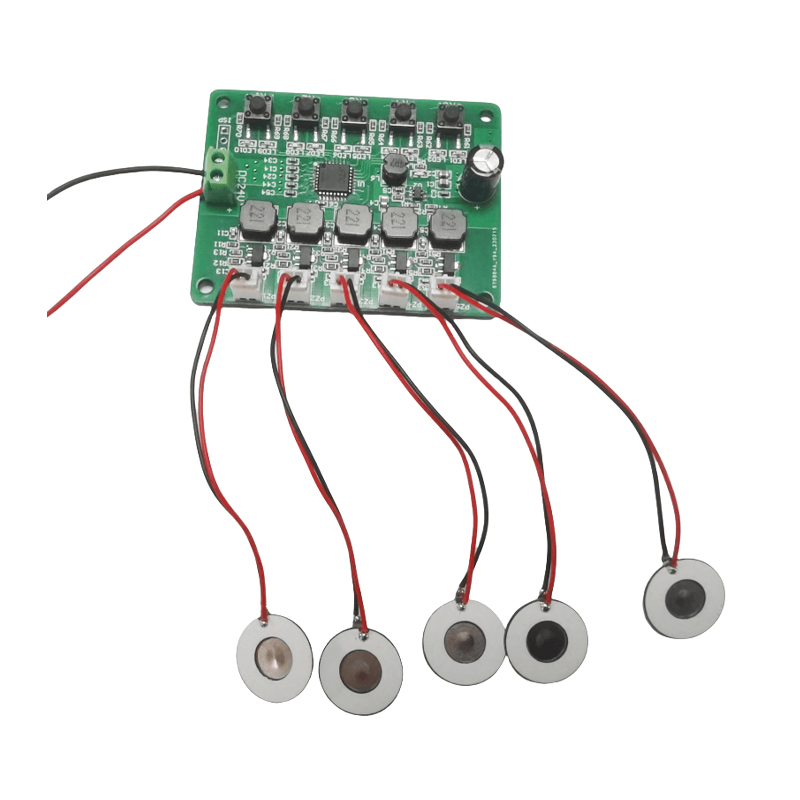

How Mesh Nebulizer Chips Work

A mesh nebulizer chip contains thousands of microscopic laser-drilled holes that vibrate at ultrasonic frequencies to create uniform aerosol particles. This advanced technology allows for consistent particle sizes between 1-5 microns, ensuring optimal lung deposition. Unlike conventional systems, mesh nebulizer chips operate silently while delivering medication more efficiently, with up to 90% of the drug reaching the lungs. Their low residual volume design minimizes medication waste, making them particularly valuable for expensive biologics and pediatric treatments.

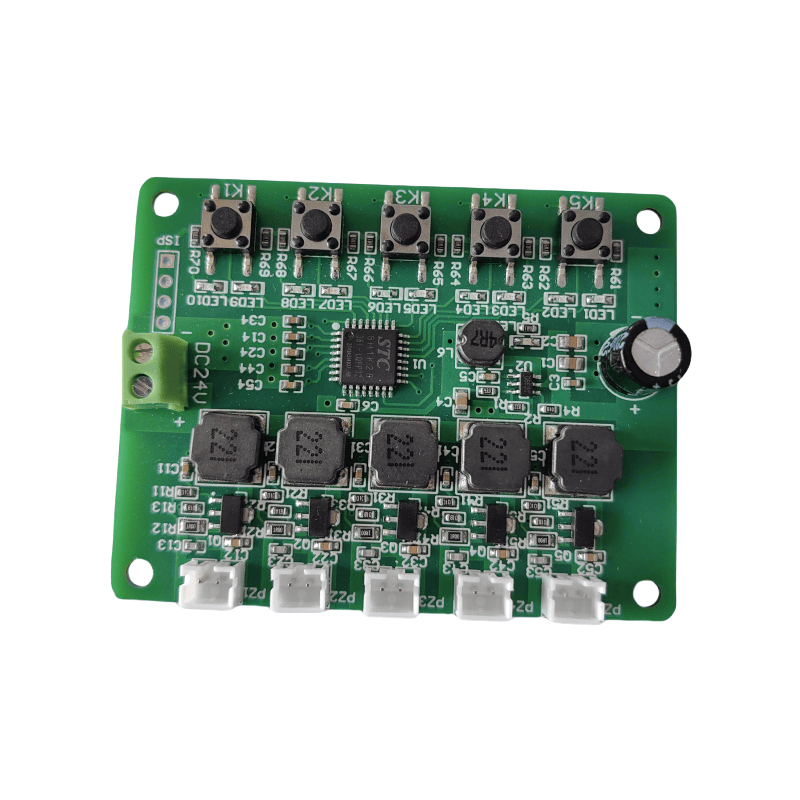

Key Advantages of Mesh Nebulizer Chip Technology

The compact size and energy efficiency of mesh nebulizer chips have enabled the development of portable, battery-operated devices that patients can use anywhere. These chips maintain consistent performance over thousands of actuations without the clogging issues that plague traditional systems. Medical-grade mesh nebulizer chips demonstrate exceptional chemical resistance, ensuring compatibility with a wide range of medications including corticosteroids, bronchodilators, and antibiotic formulations. Their rapid treatment times—often under 5 minutes—significantly improve patient compliance rates.

Material Innovations in Mesh Nebulizer Chips

Leading manufacturers produce mesh nebulizer chips using nickel-titanium alloys or medical-grade stainless steel for durability and precision. Recent advancements include nano-coated chips that prevent drug crystallization and self-cleaning piezoelectric designs that extend operational lifespan. The development of disposable mesh nebulizer chips has addressed cross-contamination concerns in clinical settings while maintaining the precision of reusable models. These material breakthroughs have expanded applications into neonatal care and critical care medicine where reliability is paramount.

Applications Across Respiratory Therapeutics

Hospitals increasingly adopt mesh nebulizer chip systems for emergency respiratory treatments due to their rapid delivery capabilities. Home care patients benefit from the quiet operation and ease of use provided by these advanced chips. The pharmaceutical industry utilizes mesh nebulizer chips in clinical trials to ensure precise dosing of experimental inhaled medications. Recent adaptations have enabled their use in veterinary medicine and industrial aerosol applications, demonstrating the versatility of this core technology.

Quality Standards and Manufacturing Challenges

Producing medical-grade mesh nebulizer chips requires cleanroom facilities and micron-level precision to ensure consistent hole size and distribution. Manufacturers must meet stringent ISO 13485 and FDA guidelines for medical device components. The intricate production process leads to higher per-unit costs compared to traditional nebulizer components, though this is offset by the chip's superior performance and medication efficiency. Ongoing research focuses on optimizing production yields while maintaining the exacting standards required for medical applications.

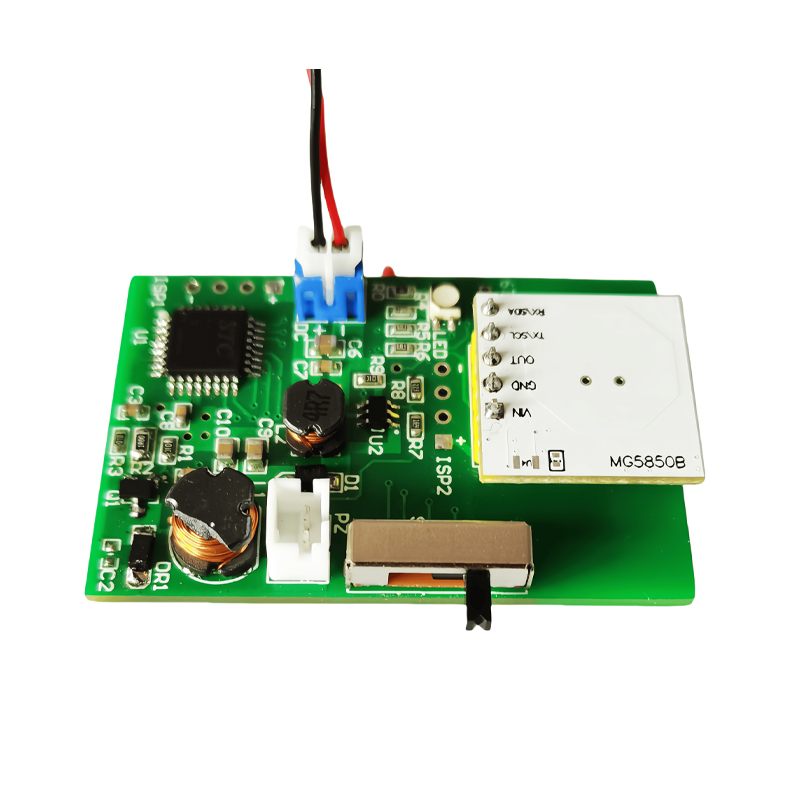

Future Developments in Mesh Nebulizer Chip Technology

Next-generation mesh nebulizer chips are incorporating smart sensors to track usage patterns and medication delivery in real-time. Researchers are developing chips with adjustable pore sizes to accommodate different drug formulations within the same device. The integration of Bluetooth connectivity with mesh nebulizer chip systems enables remote monitoring by healthcare providers. Sustainable manufacturing processes and biodegradable chip materials represent another important frontier for this essential medical technology.

English

English 中文简体

中文简体