PI Lead Free Mesh Zeroing Chip: Environmentally Friendly Innovation in the Field of Medical Atomization

PI film technology is indispensable for the excellent performance of PI lead free mesh zeroing chip in the field of medical atomization. Polyimide (PI) is a high-performance polymer material with unique physical and chemical properties. It has excellent high temperature resistance and can maintain a stable physical form in a wide temperature range, which enables the chip to maintain stable performance during long-term continuous operation or ambient temperature fluctuations. At the same time, PI film also has good chemical stability and is not easy to react chemically with drug solutions, ensuring that there will be no interference with the properties of drugs during the atomization process, and building a solid technical foundation for the reliable operation of the chip.

Cooperative microgrid structure to achieve uniform atomization

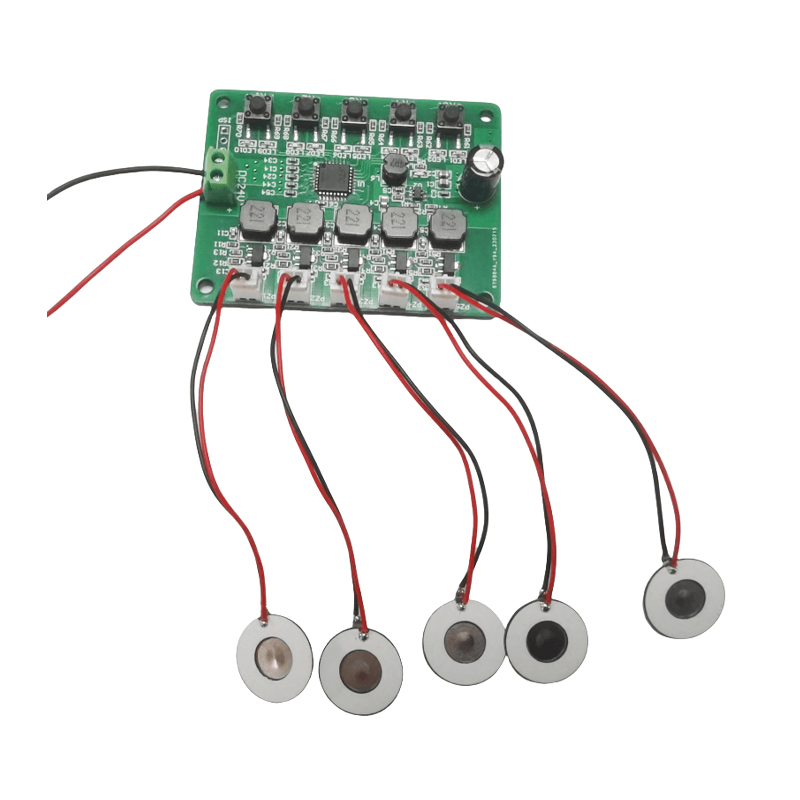

The synergy of PI film technology and chip microgrid structure is the key to achieving uniform atomization effect. The microgrid structure is responsible for cutting the drug solution into tiny particles, and the PI film, with its flexibility and fit, tightly covers the surface of the microgrid, just like putting a "protective film" on the microgrid. When working, the PI film can effectively adjust the amplitude and frequency of the microgrid vibration, so that the working state of each part of the microgrid structure is more balanced when the drug is atomized. This balanced vibration can ensure that the drug solution is evenly cut, avoiding the occurrence of local particles that are too large or too small, so that the atomized particles are more uniform overall, laying the foundation for the effective delivery of drugs.

Stable piezoelectric response to maintain consistent particle size

The stable piezoelectric response characteristics of the PI film are the core elements to maintain the consistency of particle size during the atomization process. When the chip is working, the PI film will deform under the action of the electric field, thereby driving the microgrid structure to vibrate to achieve drug atomization. Because the PI film has stable piezoelectric properties, it can convert electric field signals into mechanical vibrations with a highly consistent response degree in different working stages. This stable conversion mechanism allows the particle size generated during each drug atomization process to remain in a similar range, effectively avoiding particle size fluctuations caused by unstable piezoelectric response. Even in long-term continuous work, the PI lead free mesh zeroing chip can continue to output atomized particles with uniform particle size to ensure the stability of the treatment effect.

Enhanced controllability improves treatment and resource value

PI film technology enhances the uniformity and stability of atomized particles, which directly improves the controllability of the drug release process. When the atomized particles are uniform in size, doctors can more accurately estimate the amount of drug deposited and the distribution range in the patient's lungs, and accurately adjust the treatment plan according to the patient's specific condition. This precise drug release reduces the phenomenon of drug waste caused by the inability of drugs to effectively act on the lesions due to uneven particle size. At the same time, since the drugs can play a more precise role, the potential risk of side effects caused by excessive or unreasonable drug distribution is also reduced. For patients, not only do they get a better treatment experience, but the treatment cycle may also be shortened due to the efficient use of drugs; for the medical system, reducing drug waste means that medical resources are used more efficiently. From the dual dimensions of improving treatment effects and rationally saving resources, it fully demonstrates the technological advancement and practicality of the PI lead free mesh zeroing chip equipped with PI film technology, bringing new changes and development directions to the field of medical atomization.

English

English 中文简体

中文简体