Piezo Atomization Chips: A Comprehensive Guide to Technology, Applications, and Innovations

Introduction to Piezo Atomization Chips

What is Piezo Atomization?

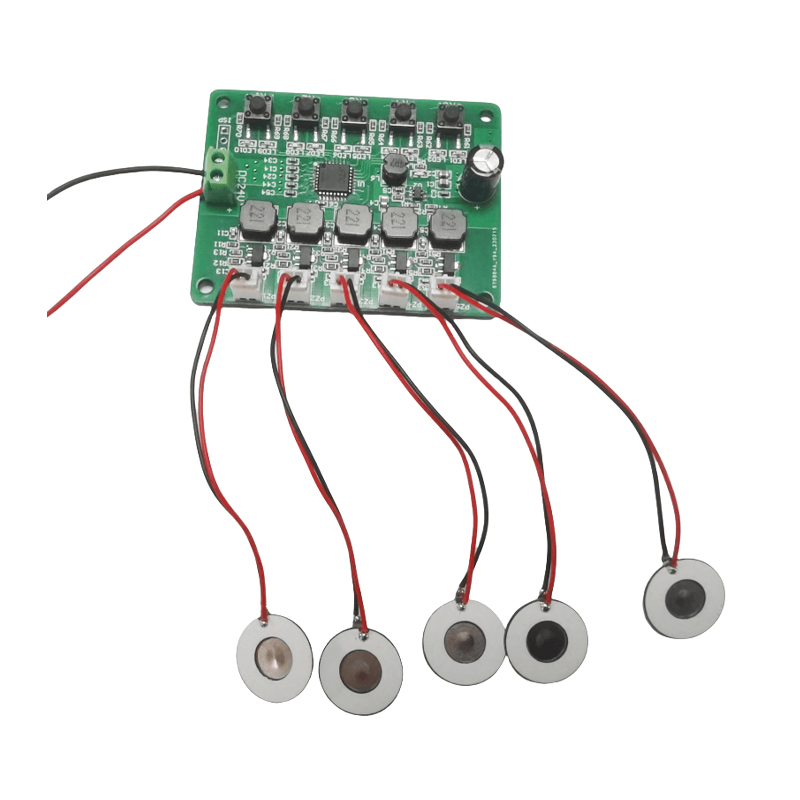

Piezo atomization represents a highly efficient method of converting liquid into fine droplets through mechanical vibration generated by piezoelectric materials. The piezo atomization chip acts as the core component in this process, transforming electrical energy into high-frequency mechanical oscillations. These oscillations create capillary waves on the surface of the liquid, eventually leading to droplet ejection.

Unlike traditional pneumatic atomization or ultrasonic atomization systems, piezo-based atomization does not rely on airflow or high-power acoustic waves. Instead, it utilizes precision-controlled vibration at the micro-scale, making it suitable for applications that require accurate droplet size control and low energy consumption. This principle is widely adopted in medical inhalers, humidifiers, industrial coatings, and agricultural sprayers.

In essence, piezo atomization is a clean, quiet, and energy-efficient technology that has gained increasing attention across industries due to its scalability and precision.

Piezoelectric Effect in Atomization

The piezoelectric effect is the fundamental physical principle behind the piezo atomization chip. It describes the phenomenon in which certain crystalline materials, such as lead zirconate titanate (PZT) or quartz, generate mechanical strain when an electric field is applied. When an alternating voltage is introduced, the material rapidly expands and contracts, producing vibrations at ultrasonic frequencies.

In the context of atomization, this vibration is transmitted to a liquid film resting on the chip’s surface. The mechanical energy causes surface instability, leading to the breakup of the liquid layer into uniform microdroplets—a process known as microdroplet generation. The precise frequency and amplitude of the vibration determine the droplet size and distribution.

This electro-mechanical conversion allows for consistent atomization without external heating or pressurization, offering enhanced safety and material compatibility. As a result, the piezoelectric atomizer has become a crucial element in modern nebulization technology, combining compactness with high performance.

Advantages of Piezo Atomization

The adoption of piezo atomization chips brings significant advantages over conventional atomization methods. The table below summarizes key differences between common atomization technologies.

Comparison of Atomization Technologies

| Technology Type | Driving Mechanism | Energy Efficiency | Droplet Uniformity | Noise Level | Maintenance Demand |

|---|---|---|---|---|---|

| Piezo Atomization | Piezoelectric Vibration | High | Excellent | Very Low | Low |

| Ultrasonic Atomization | Acoustic Resonance | Medium | Moderate | High | Moderate |

| Pneumatic Atomization | Compressed Airflow | Low | Variable | High | High |

From this comparison, the piezo atomization chip demonstrates clear advantages in terms of precision, power consumption, and operational stability. Its vibration-based droplet formation mechanism ensures a consistent particle size distribution, crucial in medical and industrial applications where dosage accuracy or coating uniformity is required.

Additionally, due to the absence of moving mechanical parts or air compression systems, piezo atomizers operate quietly and exhibit longer service life. Their efficiency in converting electrical energy to atomization energy also contributes to reduced operational costs, aligning with global trends toward energy-efficient and low-noise technologies.

Technology and Working Principle

Chip Design and Materials

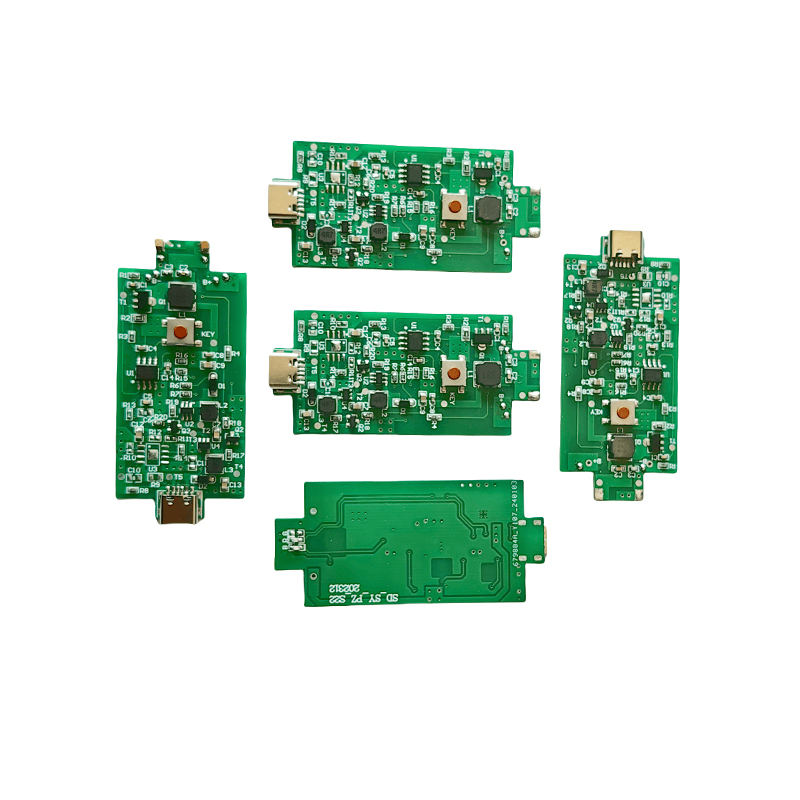

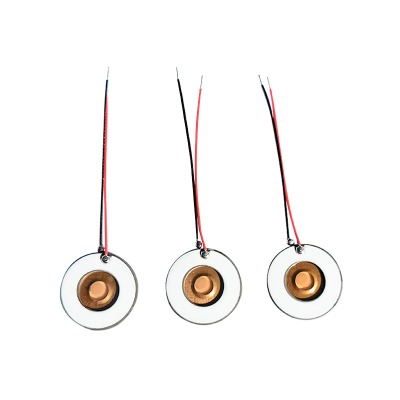

The performance and reliability of a piezo atomization chip depend heavily on its structural design and the materials used in its construction. The chip generally consists of three main layers: the piezoelectric substrate, the electrode layer, and the atomization surface. Each layer serves a specific purpose in converting electrical energy into mechanical motion and efficiently transmitting it to the liquid.

The most widely used materials for the piezoelectric substrate are Lead Zirconate Titanate (PZT) and Quartz. PZT offers high electromechanical coupling efficiency and strong deformation capability, making it ideal for applications that require high atomization output. Quartz, by contrast, provides superior temperature stability and chemical inertness, suitable for medical or chemical processes involving sensitive fluids.

The electrode layer, typically composed of thin metallic films such as gold or platinum, ensures uniform electric field distribution across the surface. The atomization surface may feature micro-holes or mesh patterns that enhance capillary action and optimize microdroplet generation.

The table below provides an overview of commonly used materials in piezo atomization chip design and their properties.

Common Materials Used in Piezo Atomization Chips

| Material Type | Example Composition | Key Properties | Typical Application |

|---|---|---|---|

| Piezoelectric Layer | PZT, Quartz | High piezoelectric constant, stability | Energy conversion |

| Electrode Layer | Gold, Platinum | High conductivity, corrosion resistance | Electrical contact |

| Atomization Surface | Stainless Steel, Silicon | Durability, smoothness, microfabrication compatibility | Liquid interaction interface |

The careful selection and integration of these materials determine not only the efficiency of atomization but also the durability and compatibility of the chip with different liquids.

Fabrication Process

The fabrication of a piezo atomization chip involves precision microfabrication techniques to ensure structural uniformity and consistent performance. The process typically includes the following key steps:

Substrate Preparation:

The base piezoelectric wafer (PZT or quartz) is cleaned and pre-treated to remove impurities and achieve a smooth surface.

Electrode Deposition:

Thin metallic films are deposited using sputtering or evaporation techniques. These layers form the upper and lower electrodes that drive vibration.

Pattern Formation:

Photolithography is used to define electrode patterns, ensuring accurate voltage distribution across the chip.

Etching and Micromachining:

Micro-holes or channels are etched into the atomization surface to facilitate liquid movement and droplet emission.

Assembly and Encapsulation:

The layers are bonded together, and the chip is encapsulated to protect it from moisture, dust, and mechanical damage.

This process combines electronic manufacturing and microelectromechanical systems (MEMS) engineering principles. The precision of fabrication directly affects droplet uniformity and frequency stability, both of which are critical for efficient nebulization technology.

Working Principle

The operation of a piezo atomization chip is based on the dynamic deformation of its piezoelectric material under an alternating electric field. When voltage is applied, the material expands and contracts periodically, generating vibrations at ultrasonic frequencies—typically between 100 kHz and several MHz.

A liquid layer positioned on the atomization surface responds to this oscillation. When the vibration amplitude exceeds the surface tension threshold, the liquid film disintegrates into fine droplets, resulting in atomized mist generation. The process can be described in three main stages:

Energy Conversion:

Electrical input is transformed into mechanical vibration via the piezoelectric effect.

Wave Propagation:

Mechanical waves travel to the liquid interface, forming standing capillary waves.

Droplet Ejection:

At critical amplitude, surface waves break, releasing uniform droplets into the surrounding medium.

The size of these droplets can be precisely controlled by adjusting the excitation frequency and the physical parameters of the chip surface. This controllability makes piezoelectric atomizers highly suitable for medical inhalers, precision coating systems, and compact humidification devices.

Through this mechanism, the piezo atomization chip achieves high-efficiency droplet formation with minimal energy loss and no need for external air pressure or heating—an advantage that underpins its growing adoption in multiple industries.

Key Parameters and Performance Metrics

Droplet Size and Distribution

One of the most critical performance indicators of a piezo atomization chip is the size and uniformity of the droplets it produces. The droplet size determines how efficiently the atomized substance interacts with air, surfaces, or human respiratory systems in medical applications. For example, smaller droplets increase surface area and diffusion rate, while larger droplets provide better deposition control in coating or agricultural uses.

The microdroplet generation process is primarily influenced by the driving frequency, vibration amplitude, liquid viscosity, and surface tension. Higher frequencies generally yield smaller droplets, while greater amplitudes increase the rate of droplet ejection. Consistent droplet distribution is a hallmark of high-quality piezo chips, ensuring stable and predictable atomization outcomes.

Factors Affecting Droplet Size and Uniformity

| Parameter | Influence on Droplet Size | Description |

|---|---|---|

| Frequency | Inversely proportional | Higher frequency → smaller droplets |

| Amplitude | Directly proportional | Larger amplitude → larger droplets |

| Viscosity | Increases droplet size | High-viscosity fluids resist breakup |

| Surface Tension | Increases droplet size | Stronger tension reduces atomization efficiency |

Precise control of these factors allows piezoelectric atomizers to produce droplets in the sub-micron to tens-of-micron range, suitable for various industrial and biomedical needs. The stability of droplet size distribution is also essential for reproducibility, especially in pharmaceutical aerosol delivery and fine coating technologies.

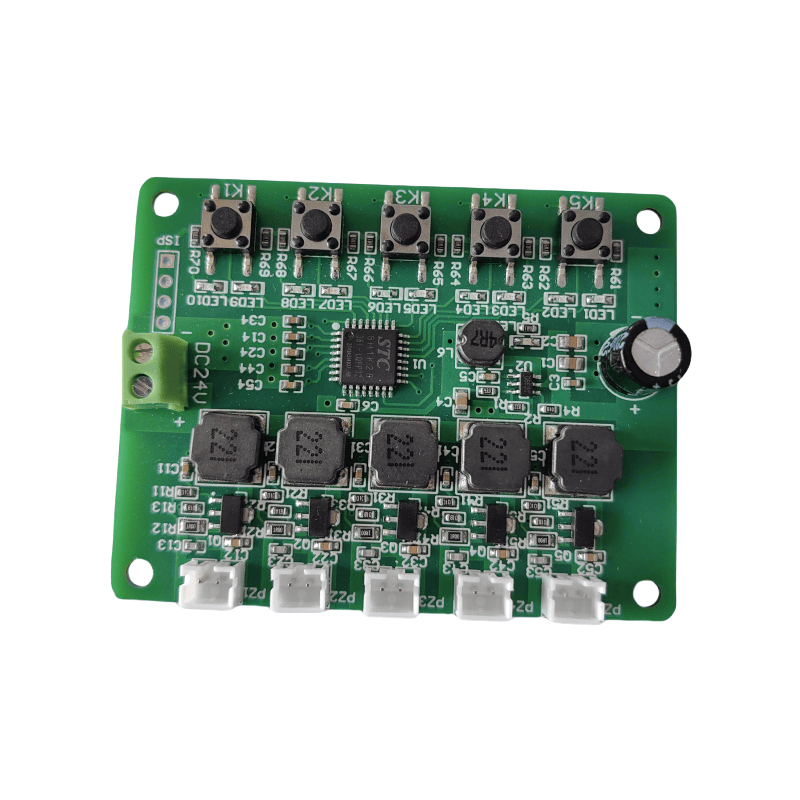

Atomization Frequency

The atomization frequency defines how many vibrations or oscillations occur per second within the piezoelectric material. It directly influences both the droplet size and the overall rate of atomization. Typical piezo atomization chips operate between 100 kHz and 2 MHz, depending on design and application.

The resonance frequency of the chip must be precisely matched with the driving signal to maximize efficiency. Operating off-resonance can cause reduced output, unstable droplet formation, or excessive power loss. Therefore, frequency tuning is a key part of system calibration.

At higher frequencies, droplet size decreases due to faster surface wave propagation and increased capillary instability. This makes high-frequency atomization particularly advantageous in nebulization technology, where fine mist production is required for respiratory therapy or controlled dispersion. Conversely, moderate frequencies are used in applications like coating and humidification, where slightly larger droplets are desired to enhance coverage and retention.

The design geometry of the chip—such as its thickness, electrode pattern, and cavity structure—also affects its natural resonance, which determines the operating frequency range. Optimizing these characteristics ensures stable performance and energy-efficient operation.

Flow Rate and Energy Consumption

The flow rate of a piezo atomization chip defines how much liquid can be atomized per unit of time. It depends on the input power, surface area, and vibration amplitude. High-frequency chips typically produce smaller droplets but lower flow rates, while lower-frequency designs can achieve greater throughput with slightly larger droplet sizes.

Energy efficiency is a major advantage of piezo atomization compared to pneumatic or ultrasonic systems. Because the chip converts electrical energy directly into mechanical motion without air compression or heating, power consumption remains minimal even at continuous operation.

Typical Performance Metrics for Piezo Atomization Chips

| Parameter | Typical Range | Performance Impact |

|---|---|---|

| Operating Frequency | 100 kHz – 2 MHz | Controls droplet size |

| Droplet Size | 1 – 30 µm | Determines application suitability |

| Flow Rate | 0.1 – 10 mL/min | Affects throughput efficiency |

| Power Consumption | <5 W | Indicates overall energy efficiency |

Efficient microdroplet generation at low energy cost makes piezo atomization ideal for battery-powered or portable devices, such as inhalers, diffusers, and handheld sprayers. Moreover, the low heat generation prevents damage to sensitive materials, preserving the integrity of liquids such as pharmaceuticals, fragrances, or biological solutions.

Applications of Piezo Atomization Chips

Medical Applications

In the medical field, the piezo atomization chip has become a vital component in modern nebulization technology, transforming how therapeutic aerosols are delivered. Traditional pneumatic nebulizers rely on compressed air to generate mist, often producing inconsistent droplet sizes and wasting medication. In contrast, piezo-based systems produce fine, uniform microdroplets using controlled vibration, enabling more efficient drug deposition in the lungs.

This high-precision control allows for optimized dosing and minimal liquid waste, which is crucial in treating respiratory conditions such as asthma or chronic obstructive pulmonary disease (COPD). Moreover, the quiet operation and low energy demand of piezoelectric atomizers enhance patient comfort and portability, allowing for compact, battery-powered inhalers.

The table below summarizes the major benefits of piezo atomization in medical applications.

Medical Advantages of Piezo Atomization Chips

| Feature | Description | Benefit |

|---|---|---|

| Controlled Droplet Size | Consistent microdroplet generation | Efficient lung absorption |

| Low Noise Operation | No compressed air mechanism | Enhanced user comfort |

| Portable Design | Compact and lightweight | Suitable for home or travel use |

| Energy Efficiency | Minimal power consumption | Extended battery life |

Through these features, piezo atomization chips have established themselves as the foundation for next-generation inhalation and nebulization systems, delivering both precision and patient convenience.

Industrial Applications

Industrial processes increasingly adopt piezo atomization chips for precision coating, surface treatment, and spray deposition tasks. Traditional spraying technologies, such as pneumatic or hydraulic systems, often face challenges in droplet control, overspray, and energy consumption. Piezo-based atomization, however, offers micrometer-level droplet uniformity and tunable flow rates, ensuring consistent layer thickness and minimal material waste.

Industries employing thin film coatings, lubricants, adhesives, or conductive materials can achieve significant performance improvements through accurate atomization control. Because microdroplet generation is achieved through vibration rather than pressurization, the process remains clean and reduces the need for complex nozzle maintenance.

Industrial Uses of Piezo Atomization Chips

| Application Type | Function | Advantage |

|---|---|---|

| Precision Coating | Controlled layer deposition | High uniformity and reduced waste |

| Cooling and Lubrication | Localized mist spraying | Improved efficiency and safety |

| Ink and Film Deposition | Controlled droplet delivery | Smooth, defect-free coatings |

In addition, the low-temperature operation of piezo atomizers makes them compatible with thermally sensitive materials, which is essential in electronics and advanced material manufacturing.

Consumer Electronics

In consumer products, the piezo atomization chip is widely used in humidifiers, fragrance diffusers, and air purifiers. These devices benefit from the chip’s ability to generate a consistent mist without heating, thereby preserving the natural properties of essential oils or aromatic liquids.

Compared with conventional ultrasonic humidifiers, piezo atomizers consume less energy, operate more quietly, and offer greater control over mist intensity. Their compact structure allows seamless integration into small appliances, including portable humidifiers and smart home diffusers.

Consumers increasingly prefer devices that balance performance and sustainability, and the piezoelectric atomizer aligns perfectly with this trend through its combination of low power consumption and long operational life.

Applications in Consumer Electronics

| Device Type | Role of Piezo Atomization Chip | Key Benefit |

|---|---|---|

| Humidifier | Produces cool, fine mist | Enhances air moisture and comfort |

| Aroma Diffuser | Atomizes essential oils | Maintains fragrance purity |

| Air Purifier | Delivers active mist particles | Improves air quality |

By offering silent, energy-efficient mist generation, piezo atomization technology enhances user experience and device longevity, reinforcing its value in the consumer electronics market.

Agricultural Applications

Agriculture has also embraced piezo atomization chips for precision spraying of pesticides, fertilizers, and plant growth regulators. Conventional spray systems often produce uneven droplet sizes, leading to chemical waste and environmental contamination. Piezo atomizers, by contrast, allow controlled microdroplet generation that ensures uniform coverage and optimal utilization of agricultural chemicals.

Because these chips can be integrated into compact, battery-powered sprayers, they support precision agriculture practices by reducing liquid consumption and minimizing drift loss. The ability to atomize a wide range of fluids—including water-based and viscous formulations—extends their use to greenhouse environments and automated irrigation systems.

Agricultural Benefits of Piezo Atomization Chips

| Function | Impact | Benefit |

|---|---|---|

| Pesticide Spraying | Uniform droplet size | Better coverage and reduced waste |

| Fertilizer Dispersion | Controlled release | Improved nutrient efficiency |

| Smart Irrigation | Integrated mist delivery | Enhanced crop growth and water saving |

The piezoelectric atomizer thus contributes to sustainable farming by improving precision, reducing energy use, and supporting environmentally friendly agricultural practices.

Advantages of Piezo Atomization

High Precision and Control

The most prominent advantage of the piezo atomization chip lies in its ability to produce highly uniform droplets with precise size control. This precision is achieved through direct electrical excitation of the piezoelectric material, allowing vibration parameters to be finely tuned according to the desired droplet size.

Unlike mechanical or pneumatic systems, piezoelectric atomization provides real-time responsiveness. The droplet diameter can be adjusted by simply modifying the driving frequency or voltage, enabling tailored microdroplet control for specific applications such as medical aerosol delivery, micro-coating, or fragrance diffusion.

The consistency of droplet distribution also enhances process repeatability and product quality. In pharmaceutical and industrial contexts, this level of control ensures optimal material usage, minimal waste, and high reproducibility across production batches.

Comparison of Atomization Control Capabilities

| Atomization Type | Control Precision | Response Speed | Droplet Consistency |

|---|---|---|---|

| Piezo Atomization | Excellent | Instant | Highly Uniform |

| Ultrasonic Atomization | Moderate | Slow | Variable |

| Pneumatic Atomization | Low | Moderate | Inconsistent |

Such precision reinforces the piezoelectric atomizer as the preferred technology where stability, accuracy, and repeatability are critical.

Energy Efficiency

Energy efficiency is another defining strength of piezo atomization chips. These devices convert electrical energy directly into mechanical vibrations with minimal thermal loss, allowing atomization at extremely low power levels. Typical operational power is under 5 watts—significantly lower than that of ultrasonic or pneumatic systems.

This efficiency not only reduces energy costs but also enables compact, battery-powered operation in portable or wearable devices. Furthermore, because the atomization process requires no heating or pressurization, the liquid’s physical and chemical properties remain intact, making the technology suitable for sensitive biological or chemical formulations.

Energy Efficiency Characteristics

| Feature | Description | Benefit |

|---|---|---|

| Direct Energy Conversion | Electrical-to-mechanical process | Minimal power loss |

| Low Power Requirement | Operates under 5W | Compatible with portable systems |

| No Heat Generation | Prevents thermal degradation | Safe for delicate liquids |

The high energy-to-atomization efficiency ratio contributes to sustainable product design and aligns with the growing demand for eco-friendly, low-consumption technologies.

Compact Size and Portability

The miniaturization potential of piezo atomization chips makes them ideal for integration into small and portable devices. Their solid-state construction eliminates bulky mechanical components, allowing product designers to reduce system size without compromising output efficiency.

Compactness enables widespread use in consumer electronics, medical inhalers, and wearable devices, where space and power efficiency are paramount. Furthermore, the chip’s ability to operate quietly enhances user experience, particularly in personal and indoor applications such as air humidifiers and fragrance diffusers.

This combination of size reduction, silent operation, and reliable performance gives the compact atomization device a significant advantage in both consumer and professional markets.

Physical and Functional Advantages of Piezo Atomization Chips

| Characteristic | Description | Application Benefit |

|---|---|---|

| Compact Structure | Small form factor and lightweight | Easy integration into devices |

| Silent Operation | Minimal vibration noise | Comfortable user experience |

| Low Power Design | Compatible with small batteries | Portable device capability |

Through ongoing advancements in microelectromechanical systems (MEMS) fabrication, future piezo chips are expected to achieve even smaller footprints with higher output power.

Material Compatibility

A further strength of the piezo atomization chip lies in its ability to atomize a wide range of liquid types, including aqueous solutions, organic solvents, viscous fluids, and bioactive substances. Since atomization is achieved mechanically rather than thermally or pneumatically, it maintains the integrity of temperature-sensitive and volatile compounds.

This compatibility expands the scope of piezoelectric atomization across multiple industries—from pharmaceuticals and cosmetics to agriculture and fine chemical processing. The non-reactive construction materials, such as stainless steel and quartz, ensure long-term chemical stability and resistance to corrosion.

Material Compatibility of Piezo Atomization Chips

| Liquid Type | Atomization Feasibility | Common Application |

|---|---|---|

| Water-Based Solutions | Excellent | Humidifiers, inhalers |

| Organic Solvents | High | Industrial coatings |

| Viscous Liquids | Moderate | Fragrance oils, lubricants |

| Bioactive Fluids | Excellent | Medical and laboratory devices |

This versatility enables the piezoelectric atomizer to serve as a universal platform for various liquid-handling systems, promoting innovation across industries where controlled atomization is essential.

Challenges and Limitations

Material Degradation

Despite its technological maturity, the piezo atomization chip faces challenges related to material degradation over long-term use. Continuous exposure to electric fields and mechanical stress can gradually weaken the piezoelectric material, particularly under high-frequency or high-voltage operation. This leads to a reduction in vibration amplitude and, consequently, lower atomization efficiency.

Environmental factors such as humidity, temperature fluctuation, and liquid corrosiveness also accelerate material fatigue and electrode erosion. In medical and industrial settings, where continuous operation is required, such degradation may compromise device stability and service life.

To mitigate these issues, manufacturers often employ protective coatings, encapsulation techniques, or composite piezoelectric materials with improved fatigue resistance. Nonetheless, the long-term reliability of piezoelectric atomizers remains an ongoing focus of research, especially for applications requiring constant high-frequency operation.

Causes and Effects of Material Degradation in Piezo Atomization Chips

| Cause | Effect on Performance | Possible Solution |

|---|---|---|

| Electrical Fatigue | Reduced vibration response | Use of high-durability PZT composites |

| Thermal Stress | Frequency drift and delamination | Temperature control and insulation |

| Chemical Corrosion | Electrode erosion | Protective coatings and sealing |

| Mechanical Fatigue | Structural cracking | Reinforced substrate design |

Understanding and addressing these degradation mechanisms are key to extending the operational lifespan of piezo atomization systems.

Clogging and Fouling

Another critical limitation in piezo atomization chips is clogging or fouling of the atomization surface. Since most designs rely on micro-scale holes or mesh structures to facilitate microdroplet generation, any accumulation of solid residues, impurities, or dried liquid can obstruct these passages, reducing output and altering droplet uniformity.

Liquids containing dissolved salts, oils, or particulates are particularly prone to causing such blockage. This issue not only affects atomization performance but can also lead to increased energy consumption as the system compensates for reduced flow.

Preventive maintenance and smart design solutions are essential to mitigate this problem. Techniques such as hydrophobic coatings, self-cleaning ultrasonic pulses, or periodic high-frequency flushing are being explored to maintain consistent performance.

Clogging Prevention Strategies for Piezo Atomization Chips

| Cause of Clogging | Preventive Measure | Expected Outcome |

|---|---|---|

| Residue Accumulation | Surface coating and filtration | Reduced blockage frequency |

| Dried Liquid Film | Self-cleaning high-frequency mode | Automatic nozzle clearing |

| Particle Contamination | Input liquid pre-filtration | Stable droplet output |

| Oil-Based Fluid Residues | Periodic solvent cleaning | Restored atomization efficiency |

Maintaining the cleanliness of the atomization interface is therefore a key operational requirement, especially in medical and agricultural devices where reliability and hygiene are critical.

Cost Considerations

While the piezo atomization chip offers remarkable performance advantages, cost remains a significant factor limiting its widespread adoption in certain markets. The fabrication process involves high-precision steps such as thin-film deposition, micromachining, and photolithography, all of which increase manufacturing complexity and expense.

In addition, the use of advanced materials like platinum electrodes and PZT ceramics contributes to higher production costs compared to traditional atomization methods. For large-scale industrial applications where cost per unit is critical, this can affect economic feasibility.

However, ongoing innovations in microelectromechanical systems (MEMS) and material science are gradually reducing these costs. The trend toward mass production, improved wafer yields, and simplified assembly processes is expected to make piezoelectric atomizers more accessible in both consumer and industrial sectors.

Cost-Performance Factors in Piezo Atomization Technology

| Cost Factor | Impact on Price | Potential Optimization |

|---|---|---|

| Material Selection | High for PZT and noble metals | Explore low-cost ceramics or composites |

| Fabrication Complexity | Increases production time | Automate assembly and testing |

| Precision Machining | Raises tool and labor cost | Apply scalable MEMS techniques |

| System Integration | Requires calibration and control circuits | Use modular driver designs |

Achieving a balance between cost and performance remains a central challenge in scaling up piezo atomization chip production. As new materials and processes emerge, the technology is likely to become more cost-effective and widely adopted.

Recent Innovations and Future Trends

Advanced Material Engineering

Recent advancements in material science have significantly enhanced the performance and durability of the piezo atomization chip. Researchers are exploring novel piezoelectric compounds and nanocomposite materials to improve energy conversion efficiency, temperature stability, and corrosion resistance.

Among these, lead-free piezoelectric ceramics such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT) have gained attention as environmentally friendly alternatives to conventional lead zirconate titanate (PZT). These materials not only comply with environmental regulations but also offer superior fatigue resistance and stable piezoelectric coefficients under thermal stress.

Another emerging direction is nanomaterial integration, where carbon nanotubes, graphene layers, or nanosilver coatings are incorporated into the electrode or substrate. This hybrid approach enhances mechanical strength, conductivity, and energy efficiency.

Emerging Materials in Piezo Atomization Chip Development

| Material Type | Key Advantage | Application Benefit |

|---|---|---|

| KNN Ceramics | Lead-free, thermally stable | Eco-friendly atomization devices |

| BNT-based Ceramics | High fatigue resistance | Long operational lifespan |

| Graphene Electrodes | Superior conductivity | Reduced power consumption |

| CNT-Reinforced Substrates | Enhanced mechanical strength | Improved vibration durability |

These material innovations are crucial to meeting the growing demand for compact, efficient, and sustainable atomization systems.

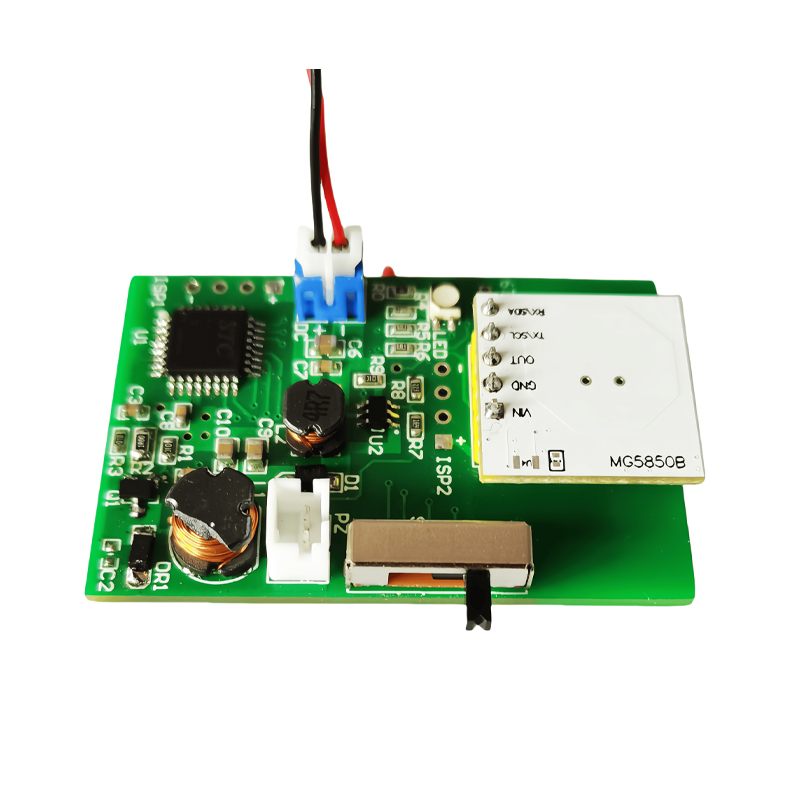

Smart and Adaptive Atomization Systems

The integration of intelligent control technologies has redefined the operation of modern piezoelectric atomizers. Advanced driver circuits and microcontrollers now allow for adaptive frequency modulation, real-time droplet feedback, and automated flow regulation.

In smart atomization systems, sensors continuously monitor parameters such as temperature, vibration amplitude, and liquid viscosity. Based on this data, the system dynamically adjusts the driving frequency and voltage to maintain optimal performance and droplet uniformity.

Such innovations are particularly impactful in fields like healthcare, where precise aerosol dosage and particle size control are critical. Similarly, agricultural sprayers and industrial humidifiers benefit from automatic adjustment to varying fluid conditions.

Key Features of Smart Piezo Atomization Systems

| Feature | Function | Impact |

|---|---|---|

| Adaptive Frequency Control | Adjusts to fluid viscosity and temperature | Maintains droplet consistency |

| Sensor-Based Feedback | Monitors atomization performance | Enables closed-loop control |

| IoT Connectivity | Remote operation and diagnostics | Facilitates smart maintenance |

| Power Optimization Algorithm | Minimizes energy usage | Enhances efficiency and lifespan |

The trend toward IoT-enabled atomization systems is accelerating, enabling data-driven control and predictive maintenance across diverse sectors.

Miniaturization and Integration

Miniaturization has become one of the defining trends in piezo atomization chip evolution. The development of MEMS-based atomizers (Micro-Electro-Mechanical Systems) enables the production of ultra-small chips with precise droplet generation capabilities, often less than 5 μm in diameter.

This miniaturization supports integration into portable or wearable devices, such as compact humidifiers, medical nebulizers, and fragrance diffusers. Additionally, integrated designs combining atomization and fluid delivery channels reduce assembly complexity and improve reliability.

Benefits of MEMS-Based Piezo Atomization Chips

| Feature | Technical Advantage | Application Example |

|---|---|---|

| Ultra-Compact Design | Space-efficient, lightweight | Wearable inhalers |

| Low Power Consumption | Optimized for portable use | Battery-operated devices |

| Precision Droplet Control | High uniformity and repeatability | Laboratory atomization |

| System Integration | Simplified assembly and control | Compact smart diffusers |

As fabrication technology advances, the boundary between microfluidics and atomization continues to blur, paving the way for next-generation miniaturized aerosol systems.

Energy Efficiency and Sustainability

Sustainability is becoming a central focus in atomization system design. Traditional ultrasonic systems often require high energy input, but recent energy-efficient piezoelectric atomizers are capable of maintaining high output with significantly lower power consumption.

Innovations such as resonant frequency optimization, low-voltage drive circuits, and thermal management structures help minimize energy loss during conversion. Moreover, the push toward recyclable materials and environmentally safe coatings reflects the broader movement toward sustainable manufacturing practices.

Energy Optimization Strategies in Piezo Atomization

| Strategy | Description | Result |

|---|---|---|

| Resonant Frequency Tuning | Operate at natural frequency for efficiency | Reduced energy loss |

| Low-Voltage Circuit Design | Optimized piezo driver architecture | Lower power consumption |

| Thermal Management | Prevents overheating and drift | Stable long-term operation |

| Recyclable Materials | Eco-friendly design choices | Reduced environmental footprint |

The combination of high atomization efficiency and eco-conscious design positions the piezo atomization chip as a leading technology in the next wave of sustainable aerosol solutions.

Conclusion

Unlike traditional ultrasonic or pneumatic atomizers, piezo-based systems rely on the piezoelectric effect—a phenomenon where mechanical vibration is generated through the application of an electric field. This process allows for the controlled production of uniform droplets without heating or chemical alteration of the liquid.

The core advantages of this technology include fine droplet size control, low energy consumption, compact structural design, and adaptability to a wide range of fluids. The material foundation, often based on ceramics like PZT or advanced lead-free alternatives such as KNN and BNT, provides mechanical strength and operational stability. Additionally, the integration of MEMS fabrication and intelligent feedback systems has greatly expanded the application potential across medical, industrial, agricultural, and consumer domains.

Key Strengths of Piezo Atomization Chip Technology

| Feature | Technical Advantage | Industrial Impact |

|---|---|---|

| Precision Droplet Generation | Uniform atomization with minimal waste | Enhanced process control |

| Low Power Operation | Efficient electrical-to-mechanical conversion | Reduced operational cost |

| Miniaturized Design | Compact, portable, and easy to integrate | Supports wearable and handheld devices |

| Material Flexibility | Compatible with diverse liquid types | Broader industry applicability |

| Environmental Compliance | Lead-free and recyclable options | Sustainable product design |

These characteristics collectively position piezo atomization as a superior alternative to conventional atomization technologies, both in terms of performance and environmental responsibility.

English

English 中文简体

中文简体