As a high-performance organic polymer material, polyimide has inherent advantages at the molecular structure level. Its macromolecular chain is composed of a rigid aromatic heterocyclic structure. This unique molecular skeleton gives polyimide excellent comprehensive performance. The surface of the PI membrane made by precision technology reaches a nano-level smoothness. This characteristic fundamentally weakens the intermolecular force between the drug solution and the membrane surface. The inherent chemical inertness of the PI membrane makes it almost non-chemically reactive when in contact with various types of atomized drug solutions, laying a solid foundation for the micro-mesh nebulizer to achieve low drug residue.

Precision machining shapes the core atomization component

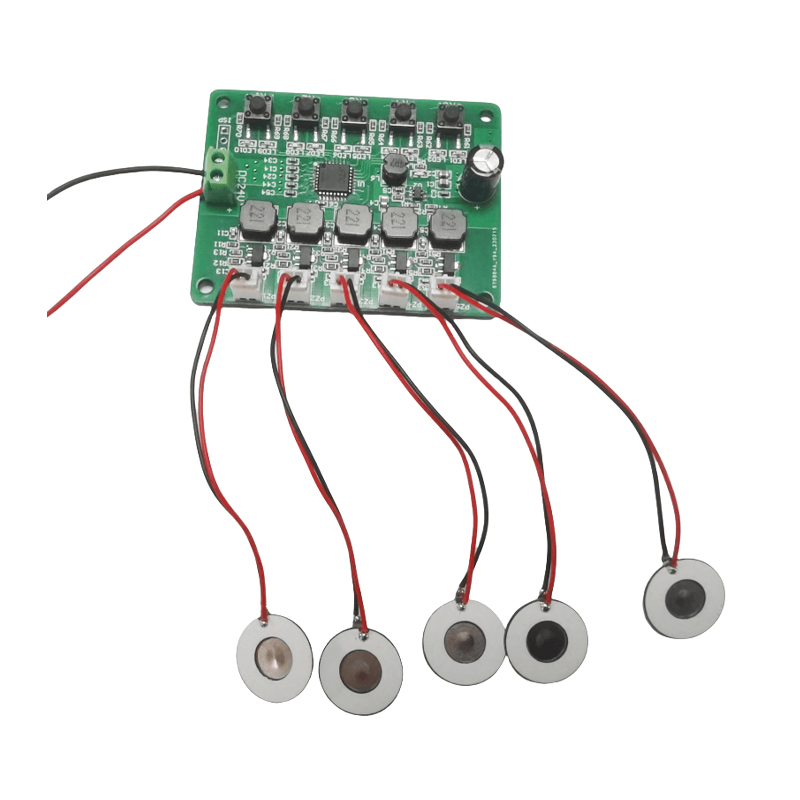

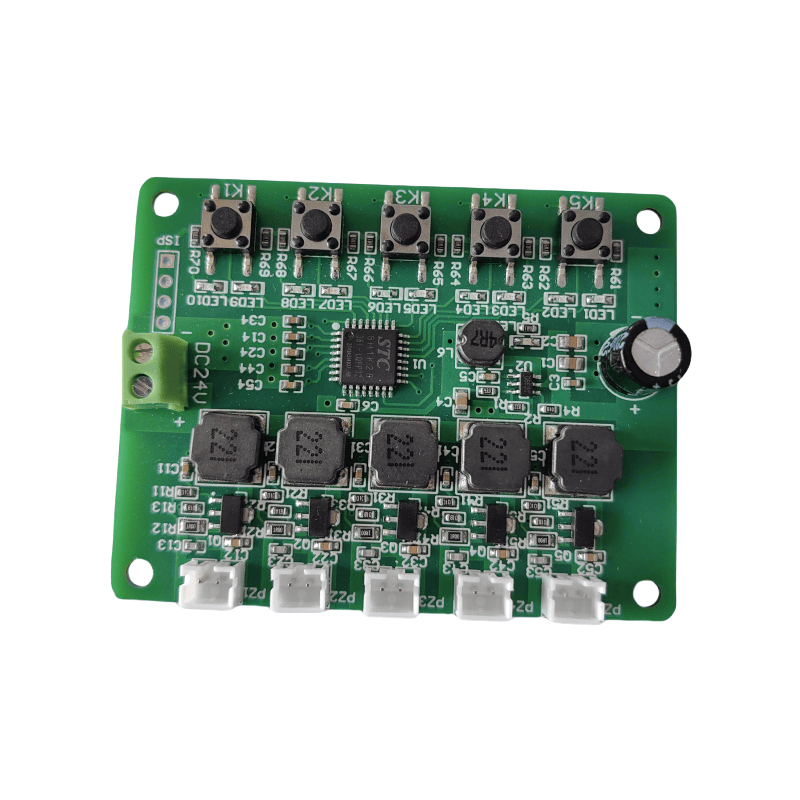

The micro-mesh nebulizer uses the PI membrane as the core atomization component and processes it precisely. The application of photolithography is like drawing a micron-level fine pattern on the surface of the PI membrane and etching a regular mesh array. The size of these meshes is precisely designed to efficiently disperse the drug solution into droplets of suitable particle size under the high-frequency vibration generated by piezoelectric ceramics. The polishing treatment of the mesh hole wall further reduces its surface roughness and makes the hole wall as smooth as a mirror. When the drug solution passes through these mesh holes under high-frequency vibration, due to the lack of sufficient adsorption sites, it is almost impossible to form physical adsorption and surface infiltration, which greatly reduces the residue of the drug solution on the hole wall.

Chemical stability ensures long-term low residue

The chemical stability of the PI membrane plays a key role in the long-term use of the micro-mesh nebulizer. Common atomized drug solutions often contain acid and alkali components, organic solvents and other substances. During long-term contact, ordinary materials may swell or have surface defects due to the erosion of these components. However, the PI membrane can withstand the erosion of these substances due to its high chemical stability, and will not produce microscopic defects due to damage to the material's own structure. Even after repeated atomization of a large amount of drug solution, the surface structure of the PI membrane can still remain intact, and the low surface roughness is continuously maintained, effectively avoiding the retention of drug solution due to structural damage, and ensuring the long-term stable low drug residue performance of the polyimide pi membranemesh micro mesh nebulizer.

Synergistic effect improves the overall efficiency of atomization

The material properties and precision processing technology of polyimide PI membrane do not exist in isolation. They cooperate with each other in the micromesh nebulizer to produce a synergistic effect. The nano-level smooth surface and extremely low roughness mesh reduce the drug residue; the high chemical stability ensures the long-term effectiveness of this low residue performance. The cooperation between PI membrane and other components of the micromesh nebulizer, such as the piezoelectric ceramic drive system, enables the drug solution to be quickly and evenly atomized through the mesh under high-frequency vibration. This integrated design from material performance to processing technology to system synergy allows the polyimide pi membranemesh micro mesh nebulizer to reduce drug residue while ensuring efficient atomization performance, significantly improving drug utilization and treatment effects.

English

English 中文简体

中文简体