Introduction

In modern atomization technology, mesh atomizer discs play a pivotal role in generating fine mist for a wide range of applications. From ultrasonic humidifiers to medical nebulizers, the mesh atomizer disc has transformed the way liquid is atomized into ultra-fine droplets. Unlike traditional atomizers that rely on simple mechanical or nozzle-based methods, mesh atomizer discs employ a precisely engineered perforated surface, enabling uniform atomization at high efficiency.

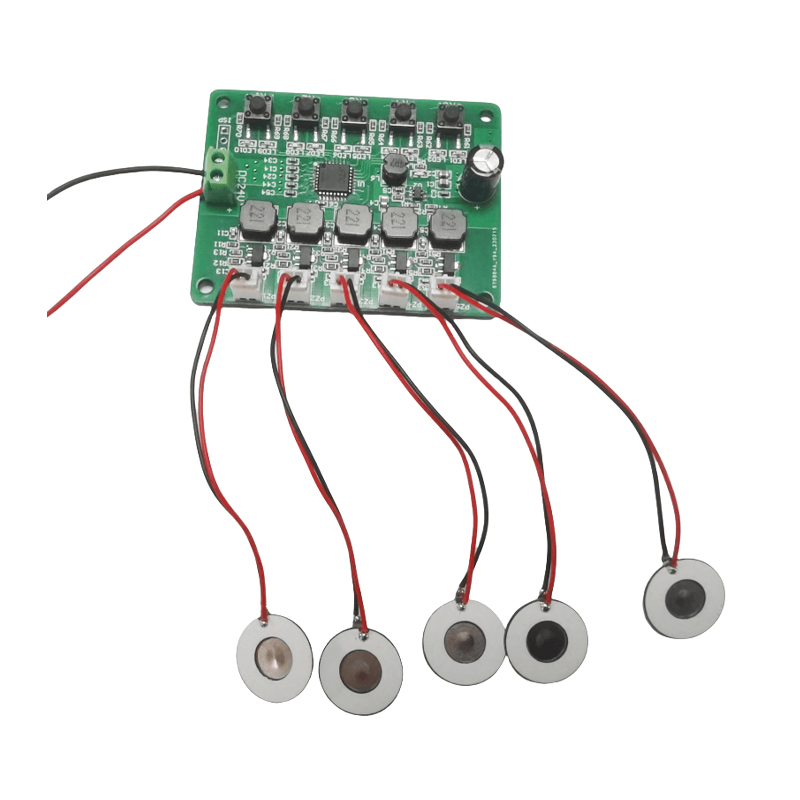

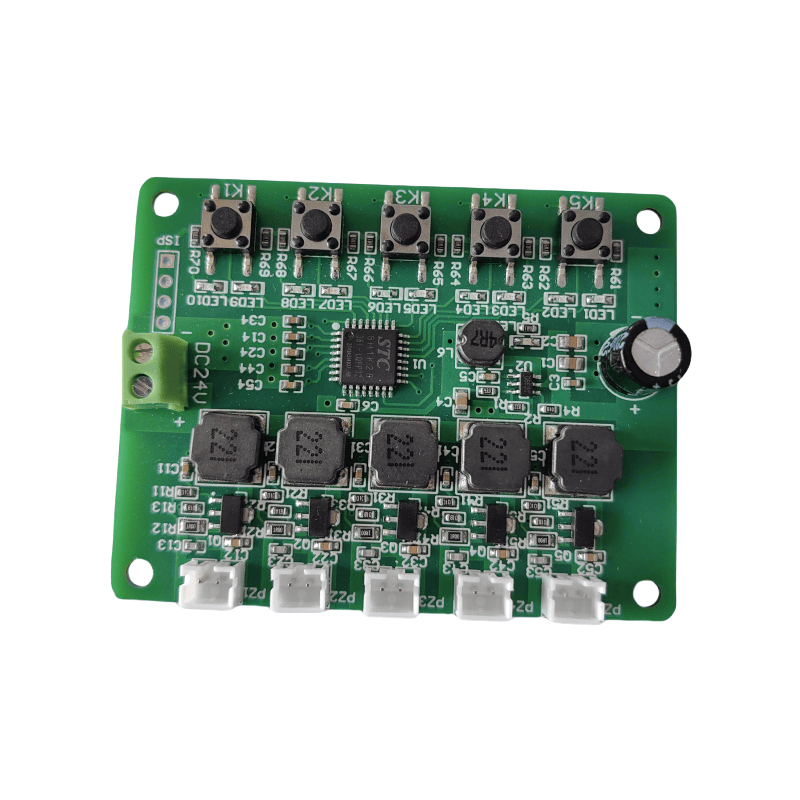

The technology behind mesh atomizer discs leverages the piezoelectric effect, which converts electrical energy into ultrasonic vibrations. These vibrations pass through the mesh, creating a high-frequency oscillation that atomizes liquid efficiently. As a result, the produced mist is not only fine but also consistent, making it ideal for both consumer and industrial applications.

Core Principle of Mesh Atomizer Discs

At the heart of every mesh atomizer disc lies the ultrasonic piezoelectric transducer. When activated, the transducer generates vibrations that resonate across the mesh surface. The perforations in the disc allow liquid to be pushed through by these ultrasonic waves, producing micro droplets. The diameter of these droplets typically ranges from 1 to 5 microns, depending on mesh size and operational frequency.

The key features of mesh atomizer discs include:

| Feature | Description | Application Benefit |

|---|---|---|

| High-frequency ultrasonic vibration | Converts electrical signals into precise oscillations | Ensures uniform droplet size |

| Perforated mesh surface | Multiple micro-holes with specific diameter | Produces ultra-fine mist efficiently |

| Piezoelectric transducer | Sensitive to electrical signals, durable | Enables silent operation and energy efficiency |

| Material coating | Ceramic or stainless steel | Extends service life and chemical resistance |

These features collectively enhance atomization efficiency and droplet consistency, which are critical in applications like portable nebulizers, aroma diffusers, and skincare devices.

Advantages of Fine Mist Generation

The primary advantage of mesh atomizer discs is their ability to generate a fine and uniform mist, which offers several benefits across different industries:

Medical Applications:

In nebulization therapy, mesh atomizer discs ensure that medication is delivered as micro droplets, allowing deeper penetration into the lungs. This fine mist improves absorption and therapeutic efficacy, making treatments more effective for respiratory conditions.

Consumer Devices:

Ultrasonic humidifiers and aroma diffusers benefit from mesh atomizer discs by producing consistent mist without wetting surfaces. The silent operation of piezoelectric mesh atomizers also enhances user comfort.

Industrial Applications:

High-efficiency mesh atomization can be applied in cooling systems, surface coating, and precision spraying, where uniform droplet size is essential for optimal performance.

The advantages can be summarized in the following table:

| Application | Benefit of Fine Mist | Example Device |

|---|---|---|

| Medical nebulizer | Deep lung penetration | Portable inhalers |

| Humidifier | Consistent moisture distribution | Home ultrasonic humidifiers |

| Aroma diffuser | Uniform scent dispersion | Essential oil diffusers |

| Industrial spraying | Efficient coverage and minimal waste | Surface coating systems |

Factors Affecting Atomization Performance

The performance of mesh atomizer discs depends on several key factors:

Mesh Size and Perforation Diameter:

Smaller perforations produce finer mist but may require higher power to maintain atomization rate. Selecting the right mesh size balances droplet size and energy consumption.

Operating Frequency:

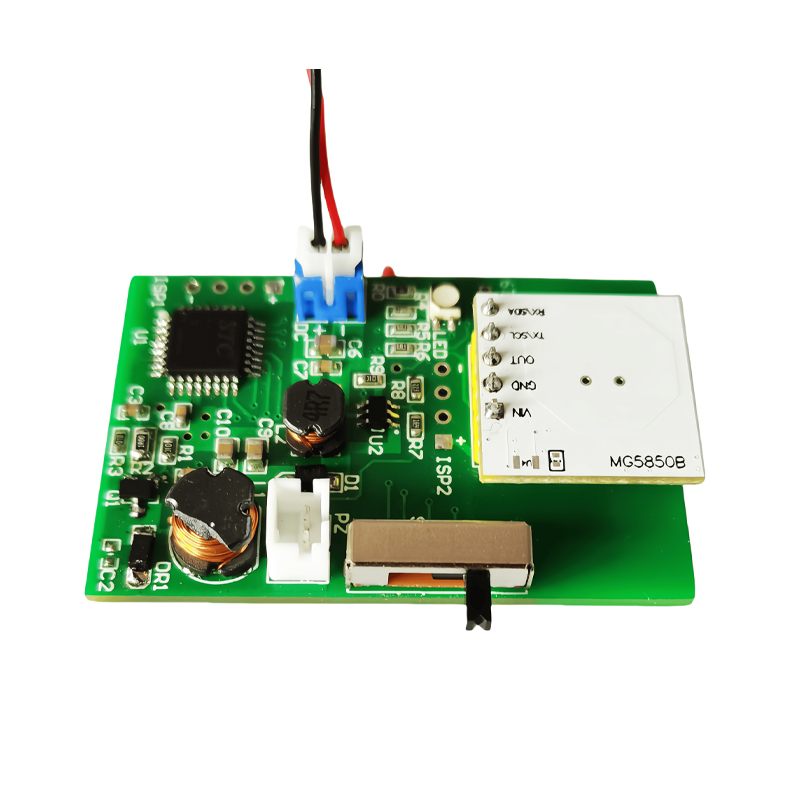

Ultrasonic frequency directly influences droplet size. High-frequency operation generates micro droplets suitable for sensitive applications, whereas lower frequencies produce slightly larger droplets for general humidification.

Material Properties:

Material selection affects durability and chemical resistance. Ceramic-coated mesh discs offer superior wear resistance and long-term stability, while stainless steel meshes are suitable for corrosive liquids.

Maintenance and Cleaning:

Accumulation of residues can reduce atomization efficiency. Regular cleaning extends the lifespan and maintains consistent mist output.

These factors are summarized in the table below:

| Factor | Impact on Performance | Recommendation |

|---|---|---|

| Mesh size | Determines droplet diameter | Choose based on desired mist fineness |

| Frequency | Affects droplet uniformity | High frequency for micro mist, low frequency for general mist |

| Material | Influences durability | Ceramic or stainless steel for long service life |

| Cleaning | Maintains efficiency | Clean regularly to prevent clogging |

Emerging Applications

Beyond traditional uses, mesh atomizer discs are expanding into new areas:

Skincare Devices: Mesh atomization technology allows the generation of nano mist for facial hydration and treatment, improving absorption of active ingredients.

Disinfection Systems: Fine mist generation ensures uniform distribution of disinfectants, improving coverage while minimizing chemical waste.

Cooling and Humidification in Smart Homes: High-frequency mesh atomizer discs enable silent, energy-efficient operation while maintaining precise humidity levels.

The adaptability of mesh atomizer discs demonstrates their technological versatility and growing relevance in diverse sectors.

Conclusion

Mesh atomizer discs represent a significant advancement in atomization technology. Their combination of piezoelectric ultrasonic vibration, precise perforated mesh, and material resilience results in ultra-fine mist with high uniformity and efficiency. By focusing on micro droplet generation, mesh atomizer discs have become indispensable in medical, consumer, and industrial applications.

English

English 中文简体

中文简体