The piezo atomization chip has emerged as a vital component in modern atomization devices, from humidifiers and aroma diffusers to medical nebulizers and industrial spray systems. Its ability to convert electrical energy into high-frequency mechanical vibrations allows it to generate a fine mist or aerosol without the need for heat. This technology, known as piezoelectric atomization, represents a significant advancement over traditional mechanical atomizers and ultrasonic atomizers, offering both efficiency and precision in liquid dispersion.

Understanding Piezo Atomization Technology

Piezo atomization chips operate on the piezoelectric effect, where certain ceramic materials generate mechanical deformation when an electric field is applied. This deformation creates rapid vibrations at frequencies often exceeding 100 kHz, leading to the formation of microscopic droplets from a liquid surface. Unlike conventional ultrasonic atomization, which relies primarily on acoustic waves, piezoelectric atomization allows for more controlled and uniform mist production.

The following table illustrates the basic differences between various atomization technologies:

| Technology | Principle of Operation | Typical Applications | Efficiency Characteristics |

|---|---|---|---|

| Piezoelectric Atomization | Electrical voltage induces vibration in chip | Humidifiers, essential oil diffusers, medical nebulizers | High precision, uniform droplet size, low energy consumption |

| Ultrasonic Atomization | Acoustic waves generate liquid surface vibration | Industrial spray, cooling systems | Moderate precision, energy-efficient, noisier than piezo |

| Mechanical Atomization | Moving parts mechanically disperse liquid | Agricultural sprayers, manual spray bottles | Low precision, higher maintenance, larger droplets |

This comparison highlights why piezo atomization chips have gained significant attention among piezo atomization chip manufacturers and end-users alike.

Key Features of Piezo Atomization Chips

Among the many advantages of piezo atomization chips, high-frequency vibration and fine droplet production are considered their most crucial features. These characteristics make them suitable for applications requiring precise aerosol delivery.

High-Frequency Operation: Piezo atomization chips can operate at frequencies ranging from 100 kHz to 1 MHz, enabling the generation of droplets often smaller than 5 microns. This high-frequency operation ensures that the atomized particles remain suspended longer, providing more uniform distribution in applications like humidification or aroma diffusion.

Energy Efficiency: Piezoelectric atomization requires significantly less energy compared to traditional heating atomizers. The minimal energy input not only reduces operational costs but also prevents liquid degradation, making it ideal for sensitive substances such as essential oils or medical solutions.

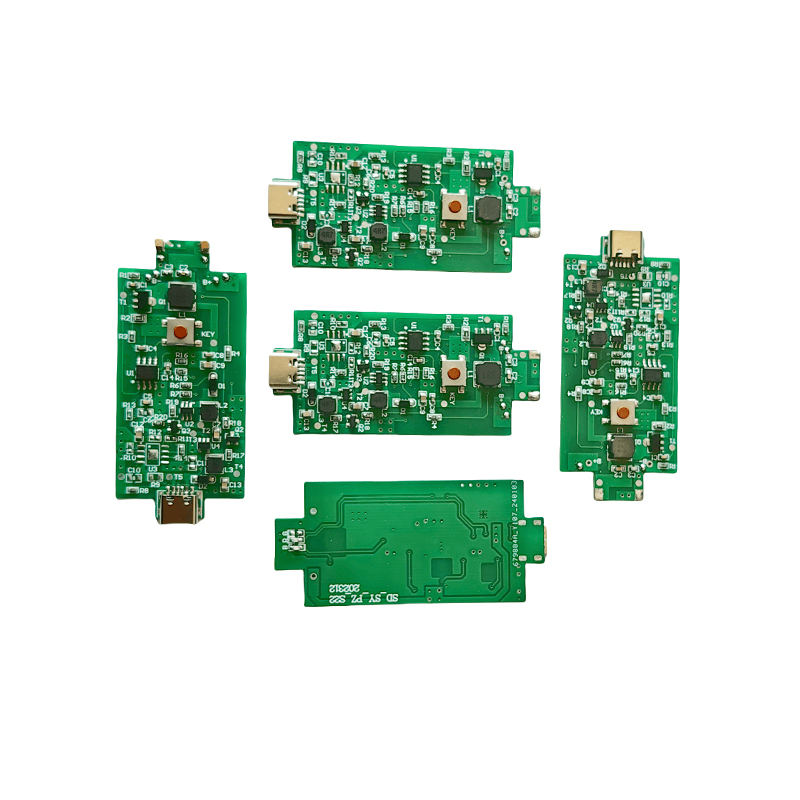

Compact Size and Versatility: Atomization chips are compact, allowing integration into portable devices and compact systems. Piezo atomization chip manufacturers often design modules that are compatible with various device forms, from handheld nebulizers to large industrial misting systems.

Durability and Low Maintenance: With no moving mechanical parts in direct contact with liquids, these chips experience less wear and tear, extending their operational life and reducing maintenance needs.

Applications in Modern Devices

Piezo atomization technology is widely adopted across multiple industries due to its precision and efficiency. Its applications can be broadly categorized as follows:

| Application Area | Description | Benefits from Piezo Atomization |

|---|---|---|

| Humidifiers | Produces fine mist to maintain indoor humidity | Uniform moisture distribution, low energy |

| Aroma Diffusers | Converts essential oils into a fragrant mist | Preserves aroma integrity, adjustable output |

| Medical Nebulizers | Delivers medication in aerosol form to respiratory pathways | Accurate dosage, minimal liquid wastage |

| Industrial Spray Systems | Fine mist for cooling, coating, or cleaning processes | Controlled droplet size, energy-efficient |

| Personal Care Devices | Skincare and facial misting devices | Gentle application, precise particle size |

Piezo atomization chips enhance these applications by providing consistent droplet size, energy efficiency, and quiet operation. This makes them particularly attractive for devices designed for home use, healthcare, and personal care.

Advantages Over Conventional Atomization

The transition from ultrasonic atomization to piezoelectric atomization represents a shift toward higher precision and efficiency. Compared to ultrasonic atomizers, piezo atomization chips offer:

Improved Droplet Control: The vibration frequency can be finely tuned, allowing manufacturers to achieve consistent particle size.

Lower Operational Noise: Piezoelectric chips generate minimal noise, making them suitable for home and medical applications.

Enhanced Compatibility with Sensitive Liquids: The low-temperature operation prevents degradation of volatile compounds or delicate solutions.

The following table highlights comparative benefits:

| Feature | Piezo Atomization Chip | Ultrasonic Atomizer |

|---|---|---|

| Droplet Size Consistency | High | Moderate |

| Energy Consumption | Low | Moderate |

| Noise Level | Low | Moderate to High |

| Liquid Compatibility | Sensitive liquids, essential oils | Mostly water-based solutions |

| Maintenance Requirements | Low | Moderate |

Technical Considerations

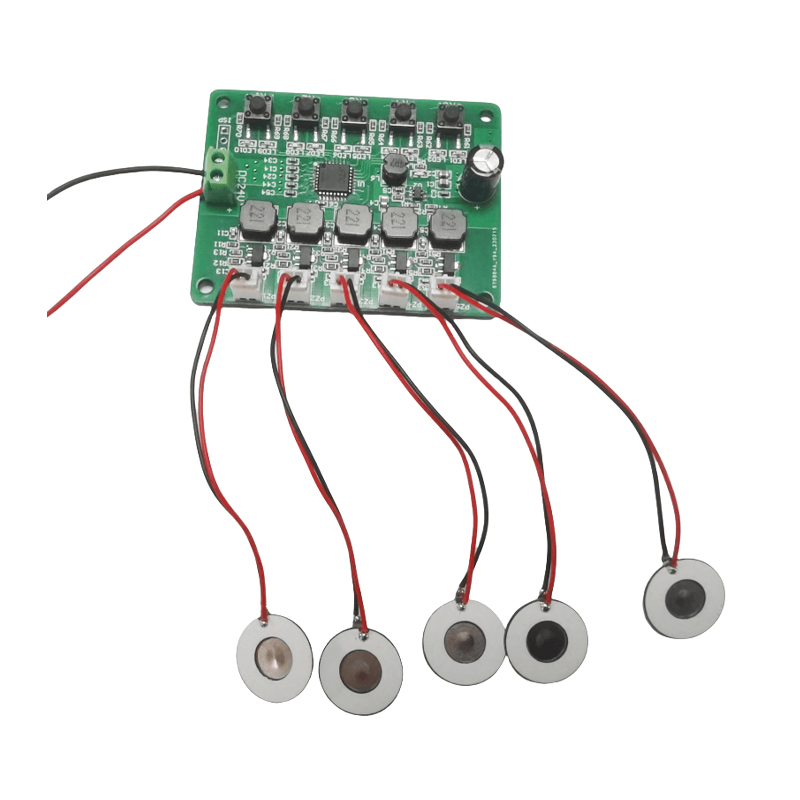

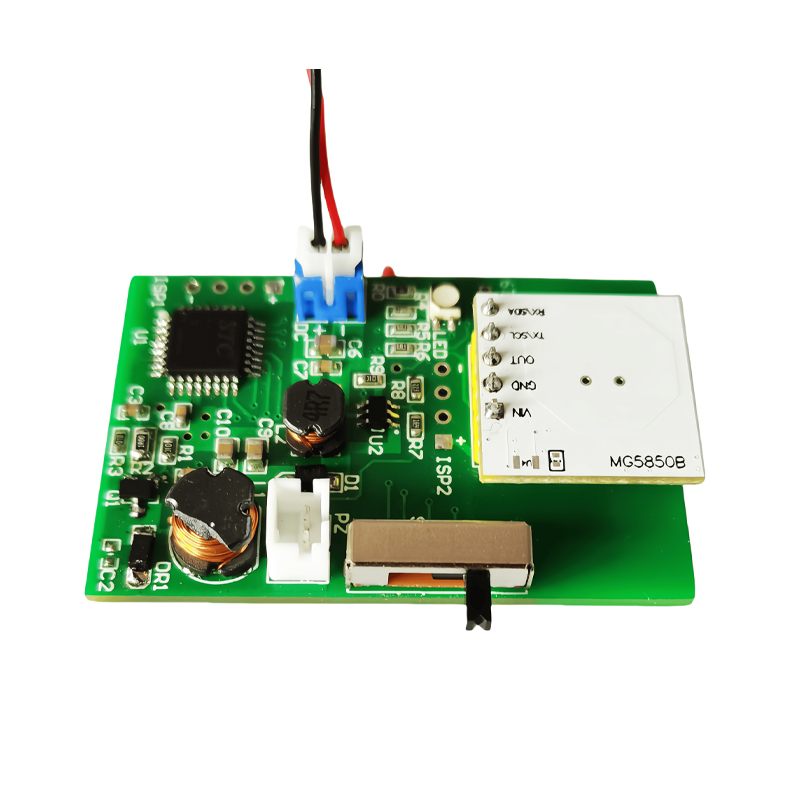

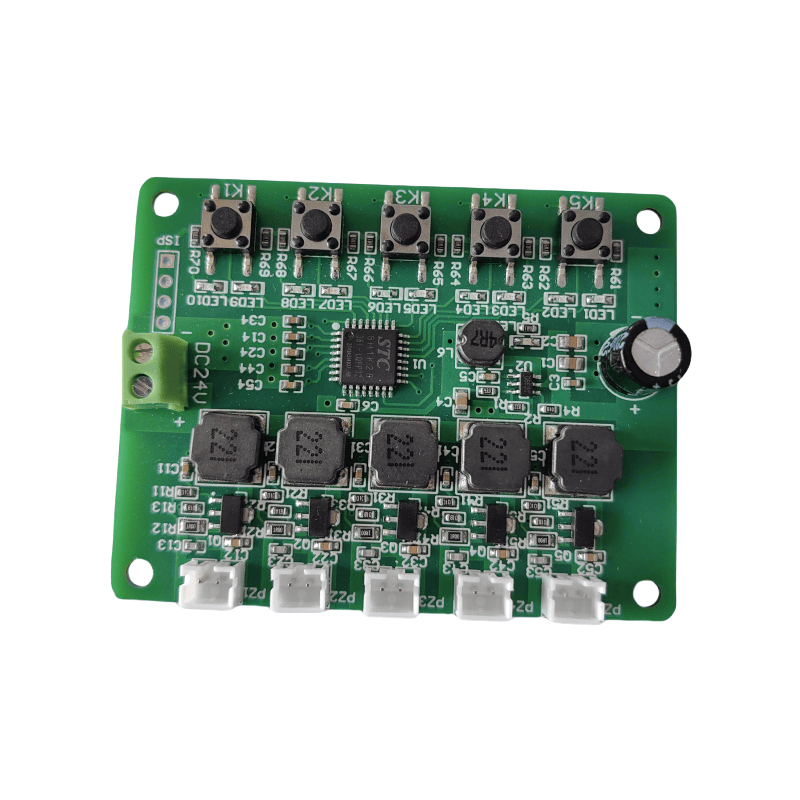

For device designers and piezo atomization chip manufacturers, several technical parameters determine the performance and suitability of a chip for specific applications:

Resonance Frequency: Determines droplet size and mist density. Higher frequencies typically produce finer droplets.

Chip Material: Most chips are made of lead zirconate titanate (PZT) ceramics, which provide optimal piezoelectric properties.

Voltage Requirements: Piezo chips operate efficiently under controlled voltage, and overvoltage can damage the chip.

Module Integration: Chips are often integrated into modules that include liquid reservoirs, control circuits, and vibration amplifiers.

| Parameter | Typical Range / Description |

|---|---|

| Resonance Frequency | 100 kHz – 1 MHz |

| Droplet Size | 1 – 10 microns |

| Voltage Requirement | 3V – 12V DC, depending on chip design |

| Material | PZT ceramic |

| Lifetime | 5,000 – 20,000 hours depending on usage |

Understanding these specifications allows manufacturers and device designers to select suitable chips for humidifiers, diffusers, or nebulizers, ensuring consistent performance and long operational life.

Market Trends and Adoption

The demand for piezo atomization chips continues to rise, driven by consumer preference for quieter, energy-efficient, and precise atomization devices. Piezo atomization chip manufacturers are increasingly focusing on developing miniaturized and high-frequency chips that can be easily integrated into compact consumer electronics as well as industrial misting systems.

Additionally, advancements in ultrasonic atomization technology complement piezoelectric solutions, enabling hybrid devices that leverage the strengths of both methods to deliver superior atomization performance.

Future Outlook

As piezoelectric atomization technology matures, future developments are expected to focus on:

Higher Atomization Efficiency: Achieving finer mist with minimal energy input.

Customizable Droplet Sizes: Allowing devices to adapt to multiple applications.

Integration with Smart Devices: Combining atomization chips with IoT-enabled systems for automated control.

Material Innovations: New piezoelectric ceramics or composites to improve durability and performance.

Piezo atomization chips are likely to remain at the core of high-performance atomization devices due to their compact size, energy efficiency, and versatility.

Conclusion

The piezo atomization chip is a revolutionary component that has transformed atomization technology. Its high-frequency vibration, energy efficiency, and precise droplet control make it indispensable in modern humidifiers, aroma diffusers, medical nebulizers, and industrial spray systems. Piezo atomization chip manufacturers continue to innovate, ensuring that atomization chips meet the evolving needs of both consumer and industrial applications.

With continued research and development, piezoelectric atomization and ultrasonic atomization technologies will further converge, delivering more efficient, precise, and versatile atomization solutions in the coming years.

English

English 中文简体

中文简体