In the evolving landscape of electronic manufacturing and healthcare technology, the printed circuit board is moving beyond its traditional applications, taking on a central role in medical devices. One of the most notable highlights is the PCB medical piezo atomizer disc, which uses advanced circuit design to drive piezoelectric components and deliver efficient and stable atomization. Discussions across the industry increasingly emphasize not only PCB manufacturing and fabrication, but also safety, customization, and performance in medical use.

Core Features of Printed Circuit Board in Medical Atomizers

Unlike consumer electronics or industrial equipment, medical devices impose stricter requirements on printed circuit board performance. Reliability and low power consumption are critical for ensuring long-term operation without failure. In the case of the PCB medical piezo atomizer disc, stability of the circuit directly determines atomization quality, particle consistency, and ultimately the therapeutic effect.

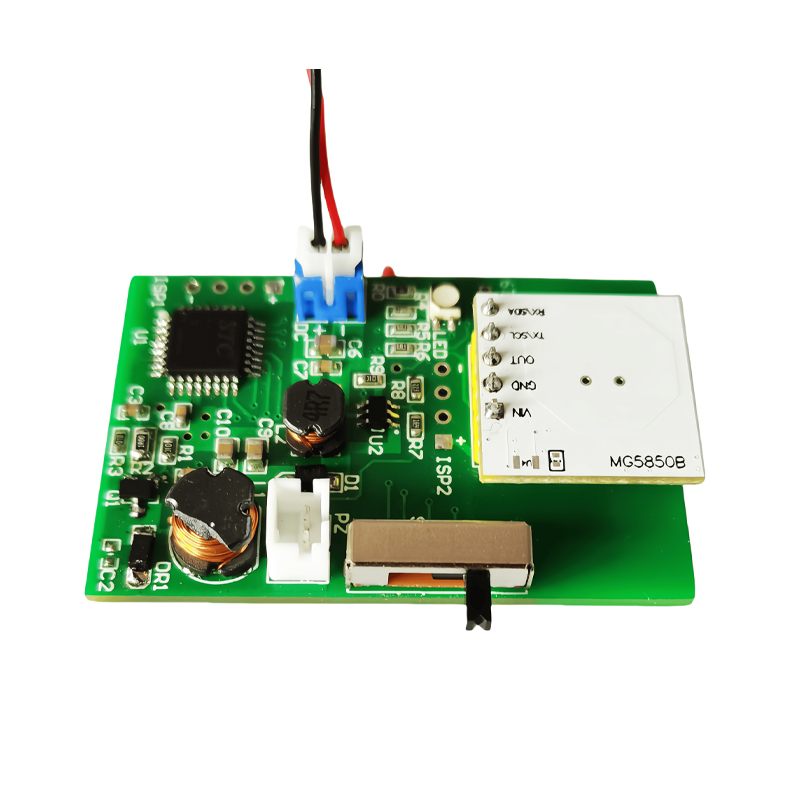

Here, the printed circuit board is not simply a substrate for electronic components. It serves as the control hub for energy conversion and delivery. This new role has driven ongoing improvements in PCB fabrication and PCB assembly tailored for healthcare applications.

The Rise of Custom Printed Circuit Board

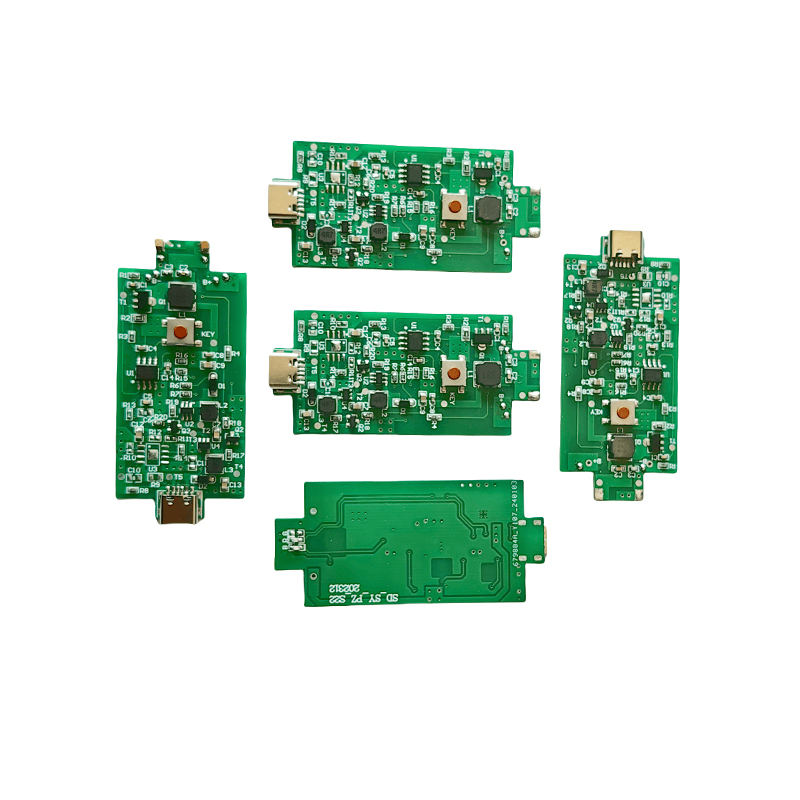

The growing diversity of medical scenarios is fueling demand for the custom printed circuit board. Different drug formulations and atomization methods require adjustments in board thickness, material selection, and layout design. For example, flexible PCB is increasingly used in miniaturized devices, while rigid PCB remains essential for high-power driver modules.

Key features of custom printed circuit board include:

Adaptability – Circuits are optimized to match atomizer disc specifications.

Material options – Flexible PCB and rigid PCB can be integrated for durability.

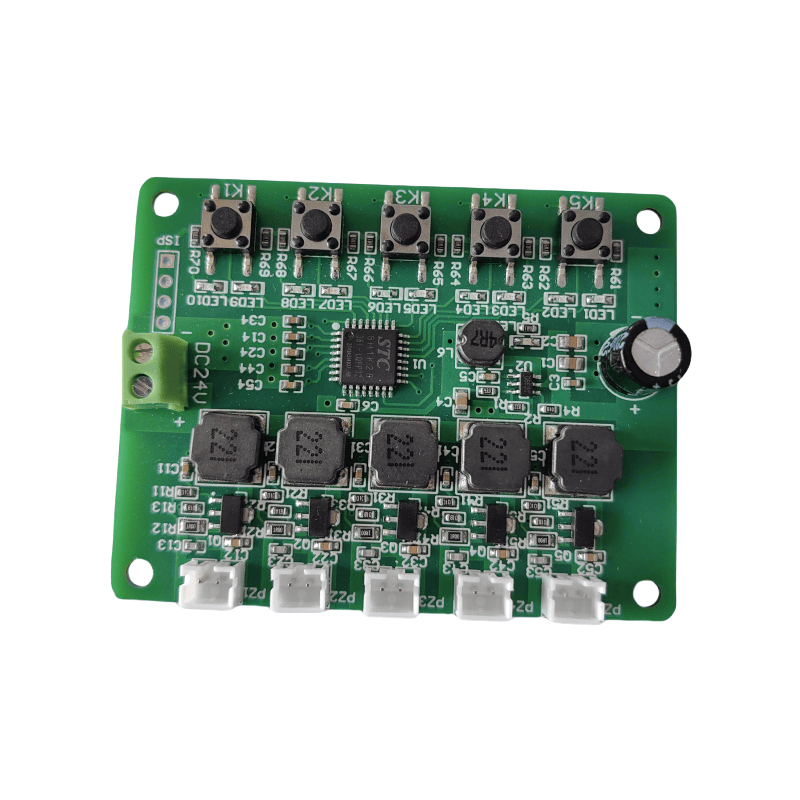

Functional expansion – Multilayer PCB design allows precise voltage and frequency control.

Role of PCB Medical Piezo Atomizer Disc

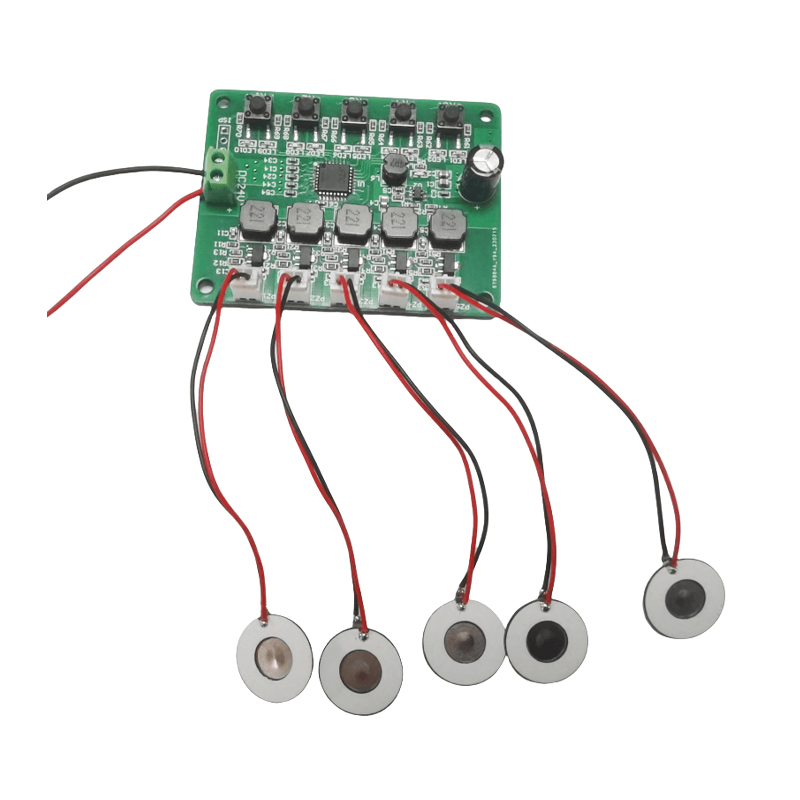

The PCB medical piezo atomizer disc has become a central topic in industry updates. The disc operates by converting electrical energy into ultrasonic vibrations via piezoelectric components, turning liquid medication into fine aerosol particles for patient inhalation.

In this process, multilayer PCB and high frequency PCB design are critical. Multiple conductive layers provide stable signal transmission, while high frequency circuits support the oscillation required for effective atomization. As a result, fine-tuned PCB design is directly linked to medical efficiency and patient outcomes.

Key Features of Printed Circuit Board in Atomizer Applications

| Feature Category | Core Performance Description | Industry Relevance |

|---|---|---|

| Circuit Stability | Efficient energy conduction, low signal distortion | Ensures consistent particle size and reliable medication delivery |

| Material Selection | Use of flexible PCB, rigid PCB, and multilayer PCB | Supports miniaturization and high-reliability devices |

| Customization | Tailored custom printed circuit board for diverse atomization needs | Enables personalized medical solutions |

| High Frequency Drive | Implementation of high frequency PCB design | Powers piezo discs for rapid, precise atomization |

| Assembly & Testing | Precision PCB assembly and strict PCB testing and inspection | Meets medical standards for safety and long-term reliability |

Industry Trends and Technical Evolution

The industry is experiencing significant progress as PCB prototype production cycles shorten and small batch manufacturing services become more accessible. This enables rapid testing of custom printed circuit board designs for atomizer discs, accelerating medical product development. Low cost PCB prototype service also plays a role in bringing new atomization technologies into clinical testing faster, supporting innovation.

Advances in multilayer PCB fabrication and high frequency PCB materials further enhance energy efficiency and signal stability in medical atomizers. At the same time, greater emphasis on PCB components and PCB testing and inspection reflects the industry’s priority on reliability and compliance with medical standards.

Outlook for Printed Circuit Board in Medical Applications

Industry perspectives consistently highlight the printed circuit board as a cornerstone of innovation in medical atomizers. Whether through diverse applications of the custom printed circuit board or precise control of the PCB medical piezo atomizer disc, advancements in PCB design and manufacturing are reshaping healthcare devices.

The integration of high-performance materials and digital PCB design tools will expand the role of the printed circuit board far beyond its traditional scope. It will serve not only as an electronic foundation but also as a driver of smart, efficient, and personalized medical technology.

English

English 中文简体

中文简体