PCB Medical Piezo Atomizer Disc Manufacturers

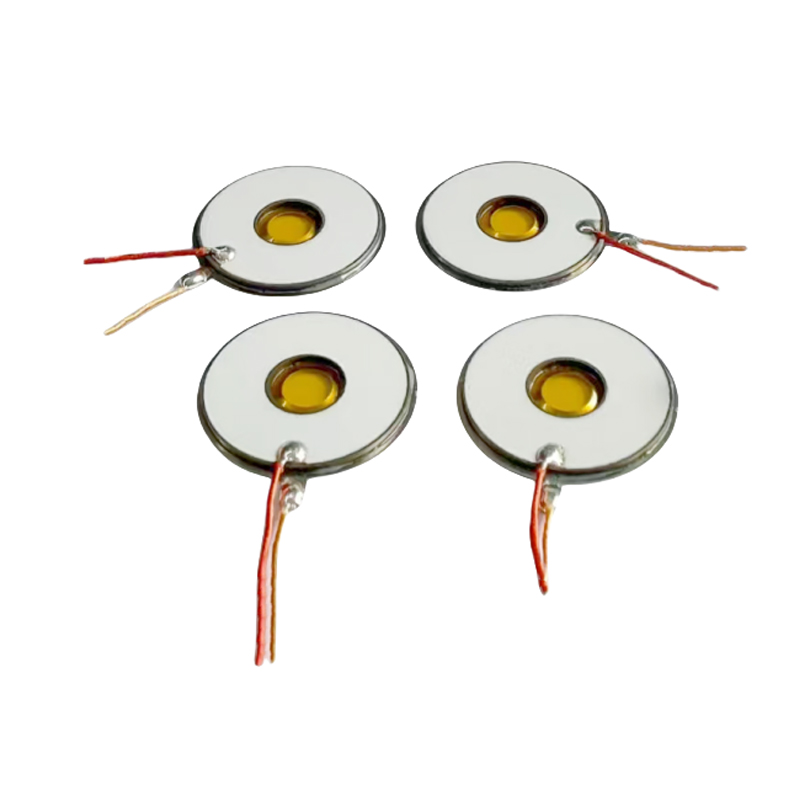

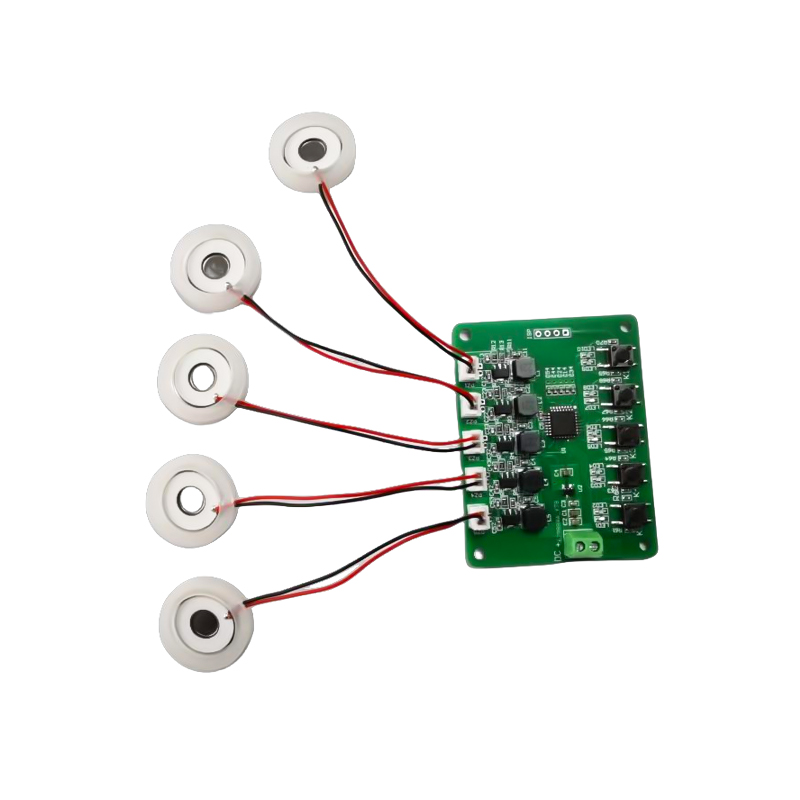

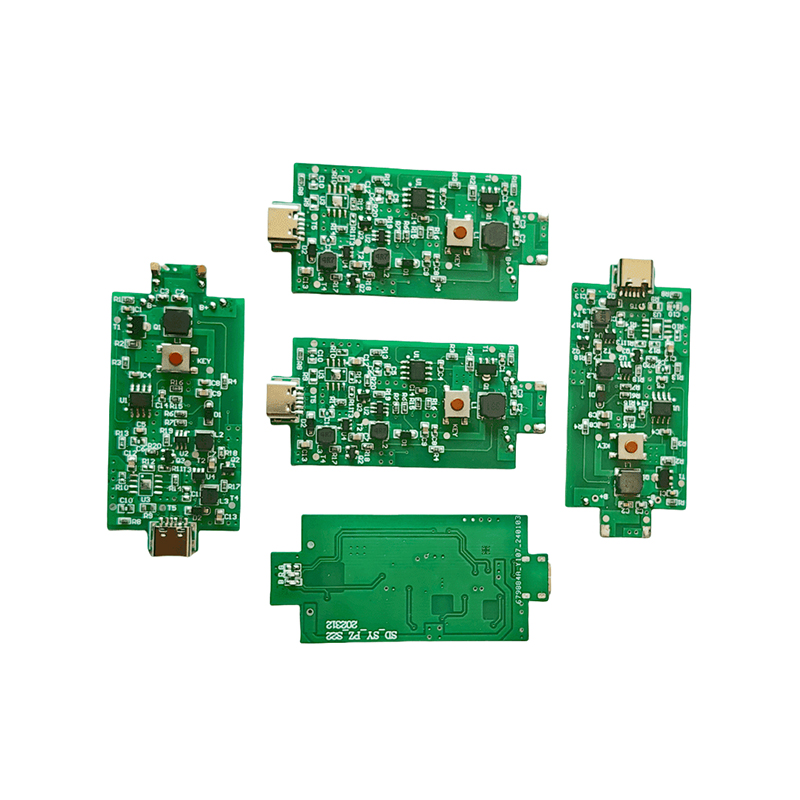

The atomization start of the nebulizer tablets needs the cooperation of PCB to be able to atomize, to achieve a good atomization effect. PCB (Printed Circuit Board) is the basis of electronic equipment, its quality directly affects the performance and reliability of medical nebulizer tablets. Therefore, manufacturers will pay special attention to the selection of PCB materials, the design accuracy of hardware and software, and the manufacturing process in the design and production process.

The selection of high-performance materials can ensure that the circuit board can work stably in various environments, while the precision design and strict manufacturing process can ensure the high precision and low failure rate of the circuit board. In addition, with technological advances, PCBs are developing in the direction of thinner, lighter, and more highly integrated, which not only helps to improve the portability of medical nebulizer tablets but also further enhances their level of intelligence. Therefore, high-quality PCB is an important guarantee for medical nebulizer tablets to achieve the goals of high efficiency, intelligence, and safety. We design preferred environmentally friendly, using lead-free solder to minimize the impact on the environment.

At the same time, in order to adapt to the use of medical nebulizer tablets in different environments, PCBs need to have good temperature resistance and EMC immunity, which contributes to a significant improvement in the performance of medical nebulizer tablets and provides patients with safer and more effective treatment options.

In addition, to further enhance the reliability of PCBs, manufacturers conduct a series of environmental adaptability tests, such as high temperature, low temperature, humidity cycling, and mechanical shock tests. These tests ensure that PCBs can still maintain stable performance under extreme conditions, thus guaranteeing the stable operation of medical nebulizer tablets in various medical environments. At the same time, with the trend of medical equipment toward intellectualization and networking, PCB design is also constantly incorporating more intelligent sensing and wireless communication functions to meet the needs of remote medical treatment and real-time monitoring. These innovations not only enhance the ease of use of medical nebulizer tablets but also bring new development opportunities to the healthcare industry.

Saida Piezoelectric is a globally renowned technology-based enterprise specializing in the production and manufacturing of medical atomization related products, we are China PCB Medical Piezo Atomizer Disc Manufacturers and Custom PCB Medical Piezo Atomizer Disc Company, We have been committed to the innovation, research and development, and promotion of ultrasonic piezoelectric ceramics, lead-free atomization products, electronic components, and related PCBA design solutions. Our goal is to improve people's quality of life through technology, and achieve a more efficient, green, and sustainable future for society.

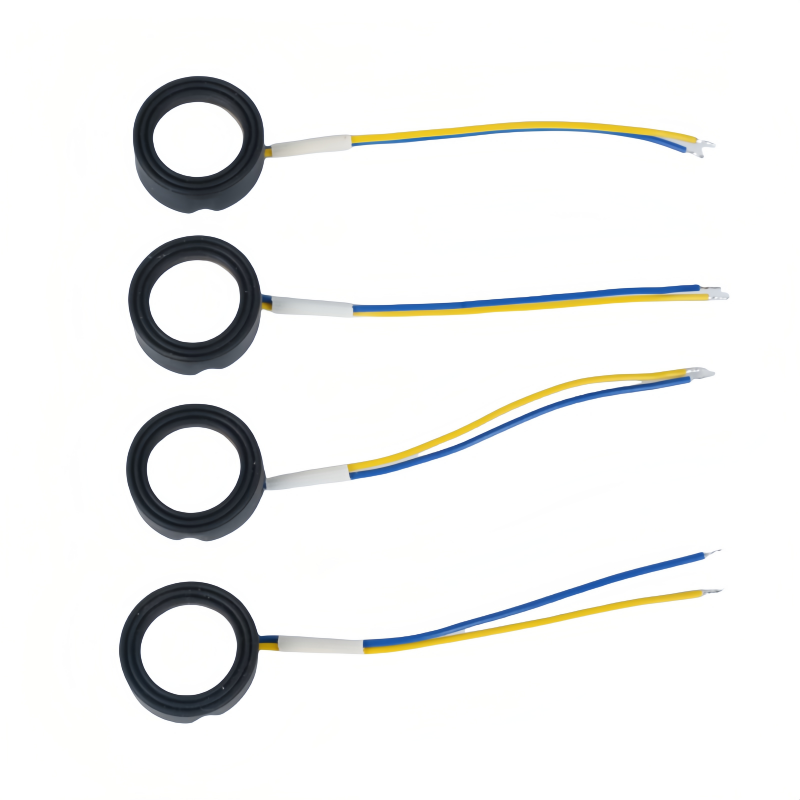

Since its establishment in April 2011, the company has been at the forefront of technological development, with an outstanding research and development team, advanced production and manufacturing equipment, and precision testing equipment. We cover a wide range of ultrasonic atomization products in our professional field, including lead based and lead-free medical inhalable atomization tablets, humidifier atomization tablets, essential oil atomization tablets, industrial atomization tablets, as well as sensing products related to ultrasonic piezoelectric and PCBA driving solutions. We not only focus on in-depth technological research and development, but also actively apply technological achievements to practical life, so that technological products can truly serve and benefit society, making the world more exciting and beautiful.

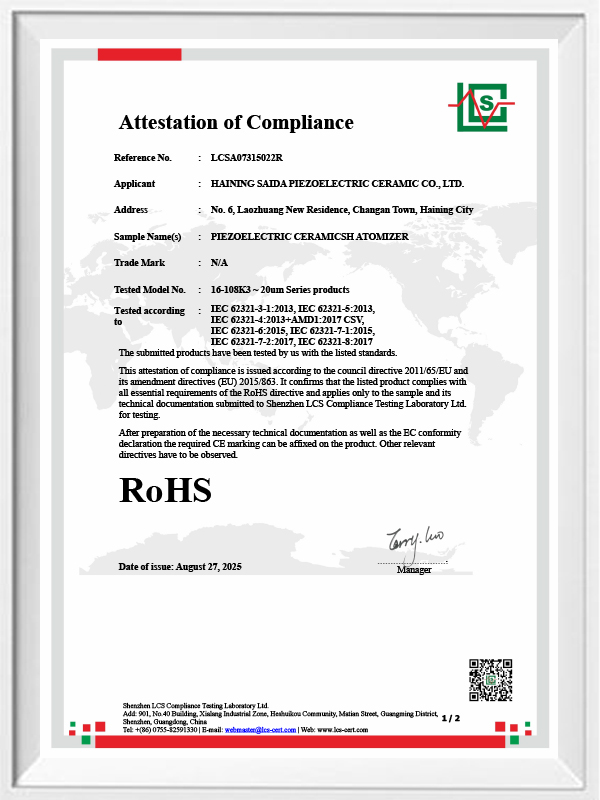

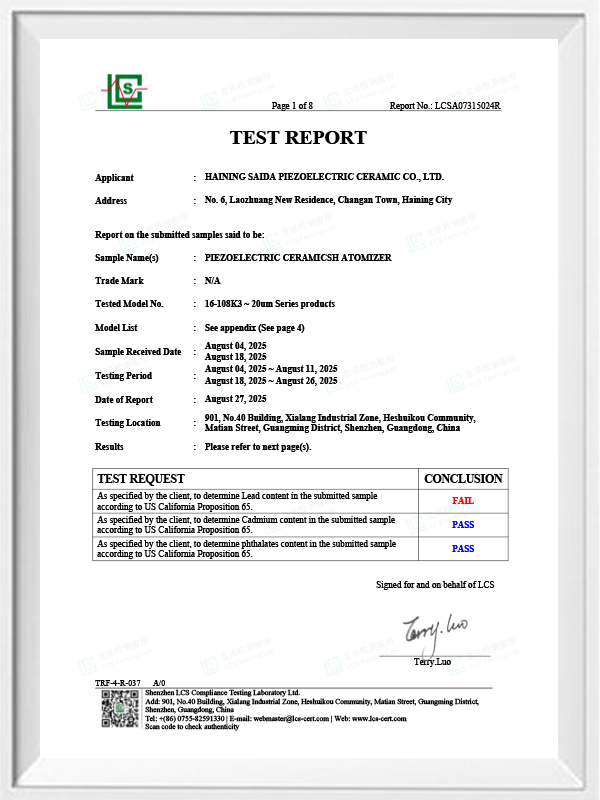

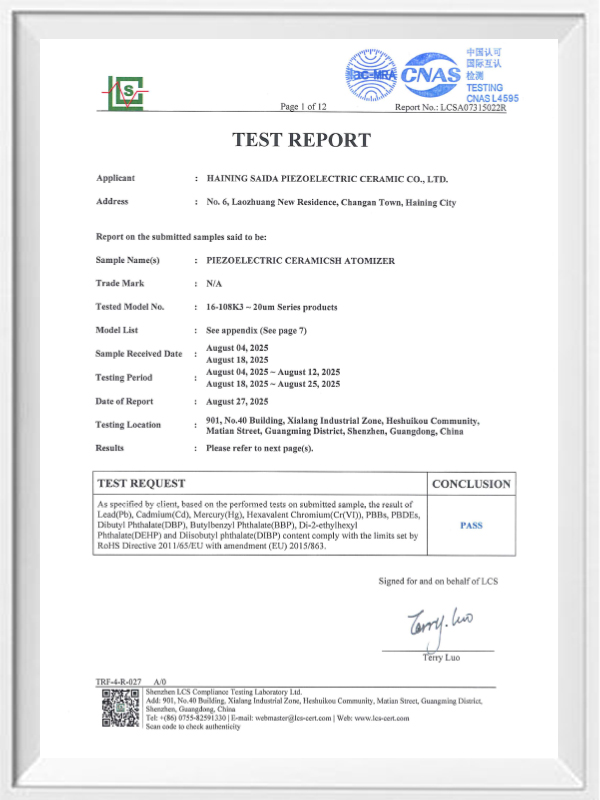

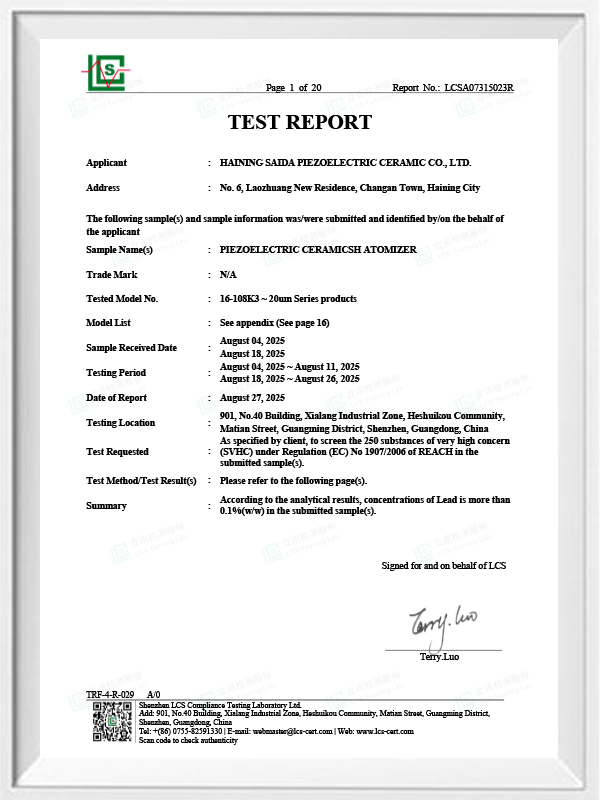

Certification

Our company's medical inhalable piezoelectric atomization series products have all passed the certifications required for export standards. They include ROHS certification, ISO9001 quality system certification, health system certification GB/T45001-2020/ISO 45001:2018, GB/T28001-2001 idt OHSAS18001:1999 Occupational Health and Safety Certification, environmental system certification GB/T24001-2016/ISO 14001:2015, California Proposition 65, REACH, and the medical atomization products have also been certified by the U.S. FDA.

news

-

Industry news

What Are the Key Benefits of Using Piezo Atomization Chips...

Introduction In the medical device industry, innovations in technology continually enhance treatment effectiveness, safety, and comfort for patients. One such breakthrough is the integration of piezo atomization chips, w...

-

Industry news

How Do Humidifier Discs Work to Maintain Optimal Humidity ...

Humidity plays a vital role in creating a comfortable living environment, particularly in regions where dry air can lead to health problems such as dry skin, respiratory issues, and discomfort. Humidifiers are essential ...

-

Industry news

How Do Medical Piezoelectric Ceramic Discs Benefit Patient...

Introduction to Medical Piezoelectric Ceramic Discs In recent years, advancements in non-invasive medical treatments have led to the introduction of innovative technologies that offer patients effective and minimally dis...

Medical Piezo Atomizer PCB Design Industry Knowledge Extension

How do piezoelectric ceramics play a role in generating high-frequency vibrations in PCB medical piezoelectric atomizer discs?

Piezoelectric ceramics, as a special material with piezoelectric effect, have unique physical properties that cause it to generate charges on its surface when subjected to external forces. Conversely, when voltage is applied to its two ends, it will deform. It is this characteristic that makes piezoelectric ceramics the core component of PCB medical piezoelectric atomizer discs, providing a continuous source of power for the atomization process.

In PCB medical piezoelectric atomizer discs, piezoelectric ceramics are carefully designed into specific shapes and sizes to ensure that they can generate stable and efficient high-frequency vibrations. When the control circuit applies an alternating electric field to the piezoelectric ceramics, the piezoelectric ceramics respond quickly and produce periodic deformations. This deformation is transmitted to the surface of the disc in the form of ultrasonic waves, which in turn excites the liquid on the disc to produce tiny droplets to achieve the atomization effect. These tiny droplets have extremely high specific surface area and can be absorbed by the human body more quickly, thereby improving the utilization efficiency and therapeutic effect of the drug.

As a well-known manufacturer of medical atomization-related products, Saida Piezoelectric has in-depth research and understanding of the application of piezoelectric ceramics in medical atomizers. Since its establishment, the company has been committed to the innovation, research and development and promotion of ultrasonic piezoelectric ceramics, lead-free atomization products and related PCBA design solutions. With an excellent R&D team, advanced production and manufacturing equipment and precision testing equipment, Saida Piezoelectric has made remarkable achievements in the field of medical atomization.

In the design and production process of PCB, Saida Piezoelectric pays special attention to the selection of materials, the design accuracy of software and hardware, and the control of manufacturing processes. The selection of high-performance materials ensures that the circuit board can work stably in various environments, while the precise design and strict manufacturing process ensure the high precision and low failure rate of the circuit board. These efforts provide a strong guarantee for the best performance of piezoelectric ceramics in PCB medical piezoelectric atomizer discs.

In addition to continuous innovation and optimization in design, Saida Piezoelectric also has a complete production equipment and testing system. The company has introduced a series of advanced equipment such as particle analyzers, metallographic microscopes, tensile testing machines, ultrasonic impedance analyzers, etc. to ensure that each PCB can meet high-precision requirements. At the same time, the company also strictly conducts full inspections in accordance with international standards and customer requirements to ensure product quality and reliability.

Saida Piezoelectric is actively exploring new directions in PCB design. The company continues to incorporate more intelligent sensing and wireless communication functions into PCB design to meet the needs of telemedicine, real-time monitoring, etc. These innovations not only improve the ease of use and convenience of medical atomizers, but also bring new development opportunities and challenges to the medical industry.

English

English 中文简体

中文简体