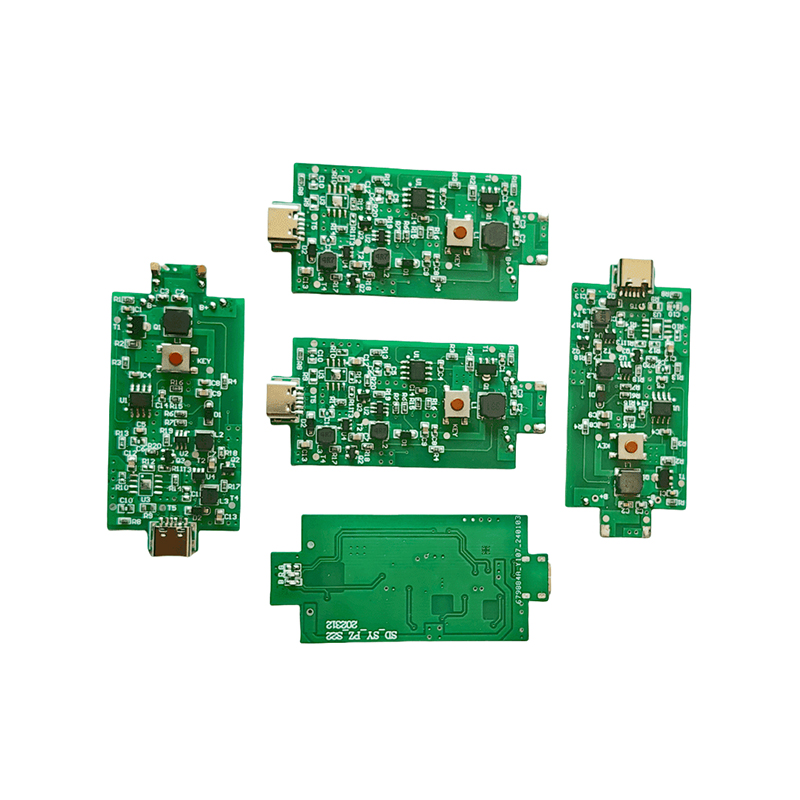

PI Lead Free Mesh Zeroing Chip Manufacturers

Saida Piezoelectric is a globally renowned technology-based enterprise specializing in the production and manufacturing of medical atomization related products, we are China PI Lead Free Mesh Zeroing Chip Manufacturers and Custom OEM/ODM PI Lead Free Mesh Zeroing Chip Company, We have been committed to the innovation, research and development, and promotion of ultrasonic piezoelectric ceramics, lead-free atomization products, electronic components, and related PCBA design solutions. Our goal is to improve people's quality of life through technology, and achieve a more efficient, green, and sustainable future for society.

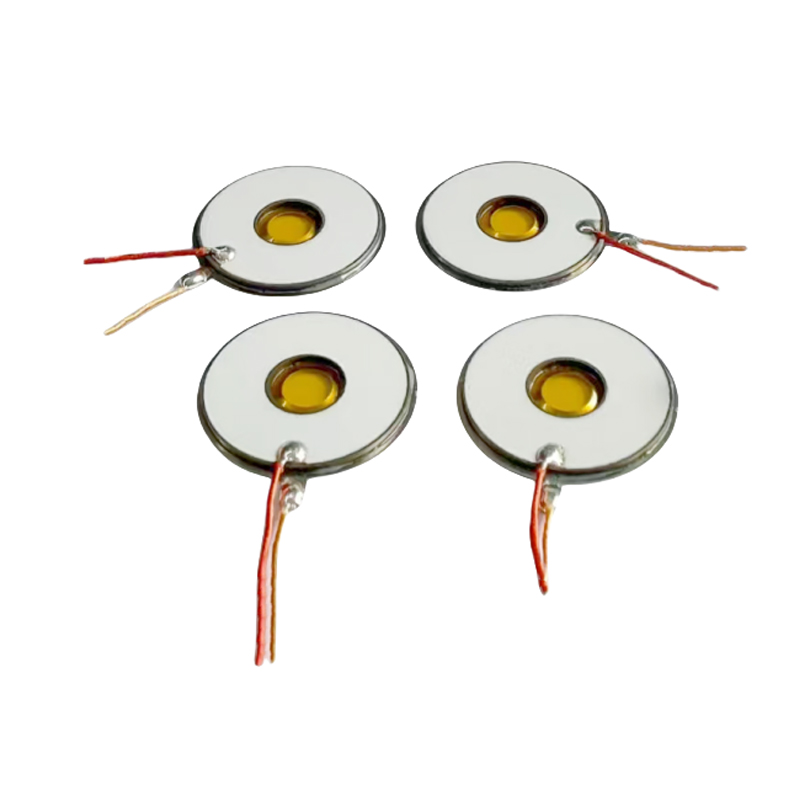

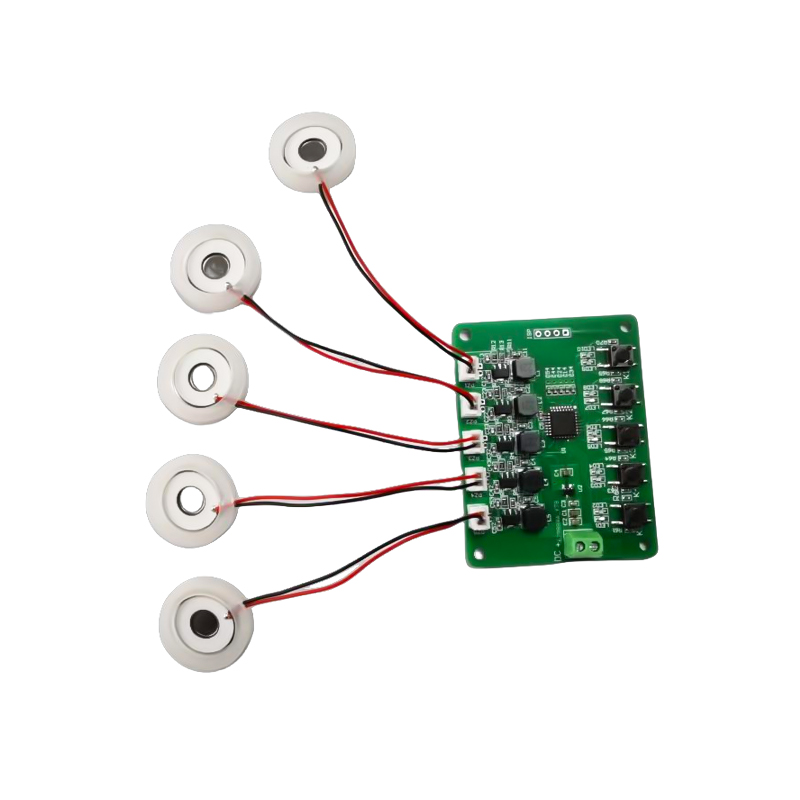

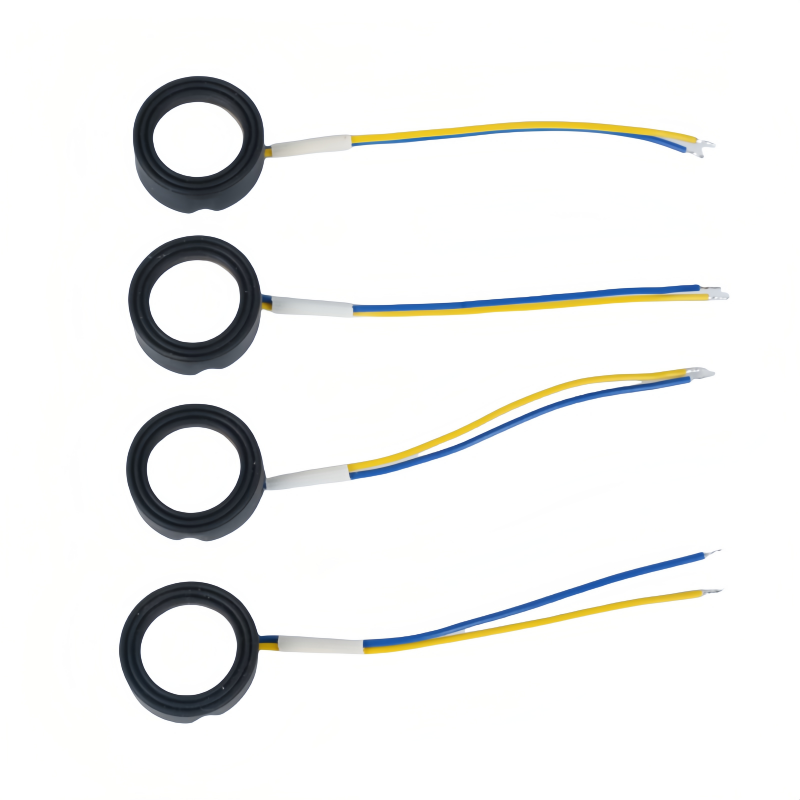

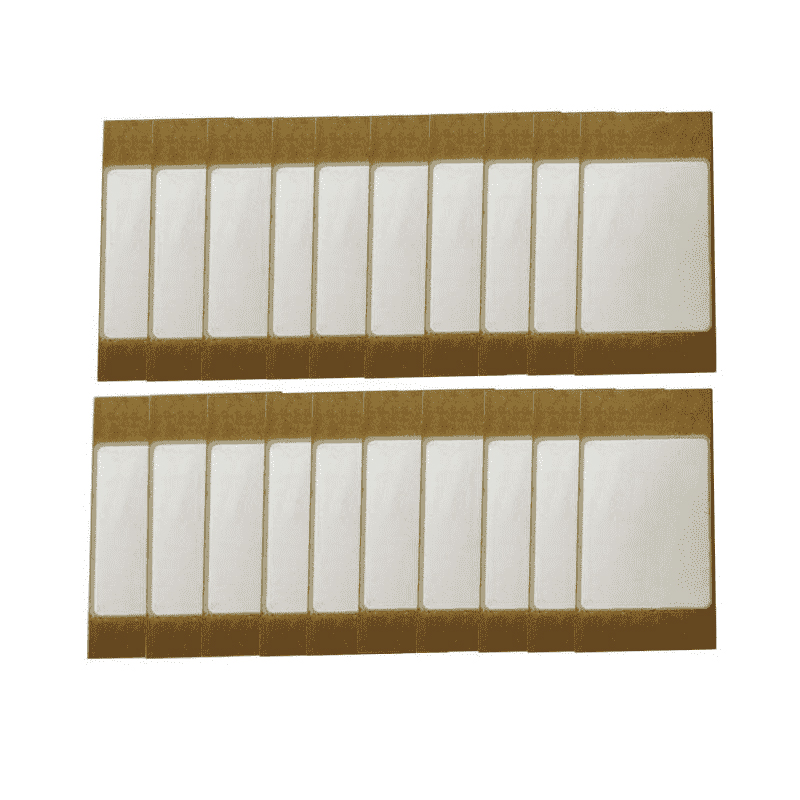

Since its establishment in April 2011, the company has been at the forefront of technological development, with an outstanding research and development team, advanced production and manufacturing equipment, and precision testing equipment. We cover a wide range of ultrasonic atomization products in our professional field, including lead based and lead-free medical inhalable atomization tablets, humidifier atomization tablets, essential oil atomization tablets, industrial atomization tablets, as well as sensing products related to ultrasonic piezoelectric and PCBA driving solutions. We not only focus on in-depth technological research and development, but also actively apply technological achievements to practical life, so that technological products can truly serve and benefit society, making the world more exciting and beautiful.

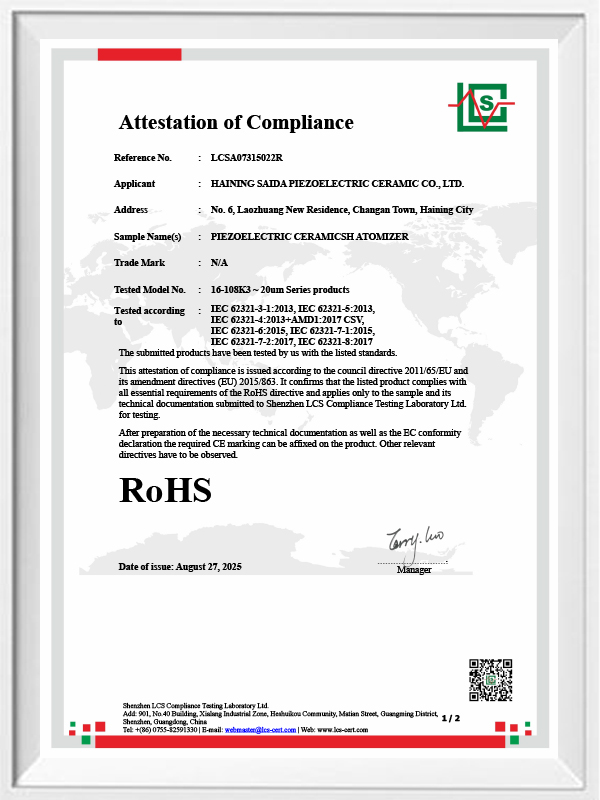

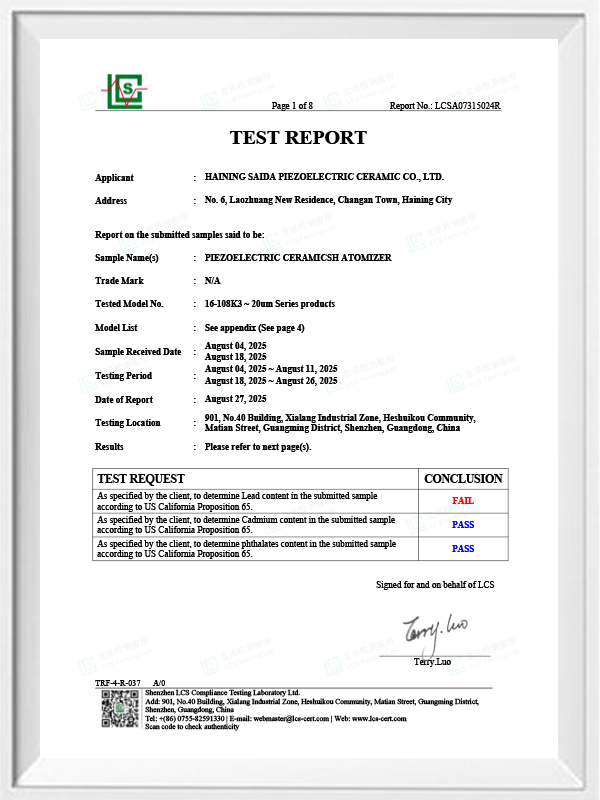

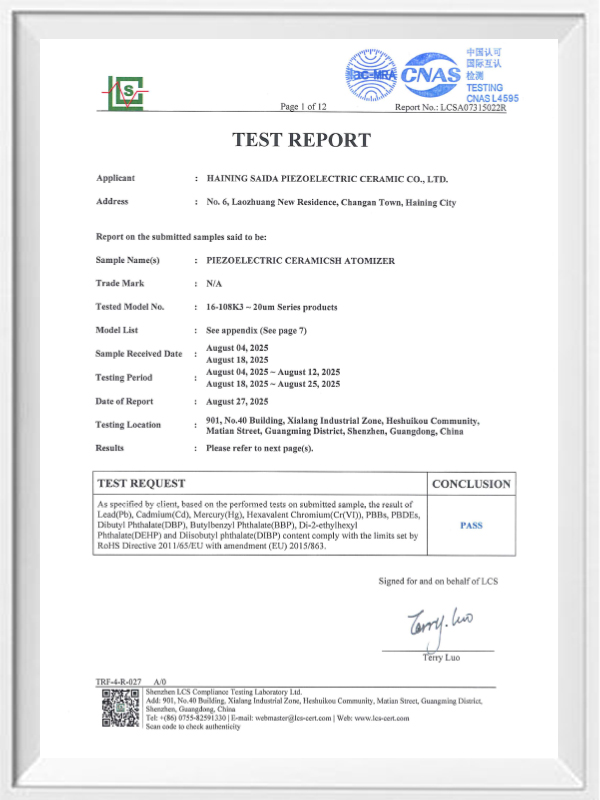

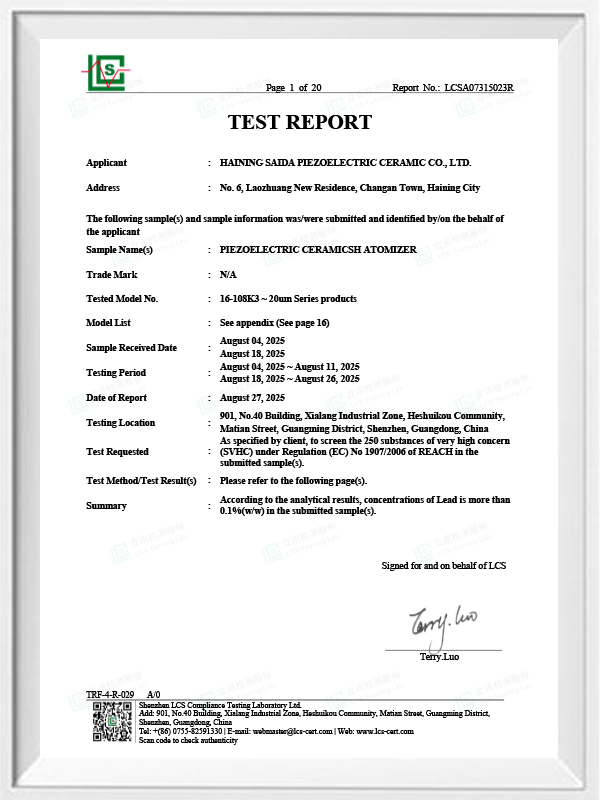

Certification

Our company's medical inhalable piezoelectric atomization series products have all passed the certifications required for export standards. They include ROHS certification, ISO9001 quality system certification, health system certification GB/T45001-2020/ISO 45001:2018, GB/T28001-2001 idt OHSAS18001:1999 Occupational Health and Safety Certification, environmental system certification GB/T24001-2016/ISO 14001:2015, California Proposition 65, REACH, and the medical atomization products have also been certified by the U.S. FDA.

news

-

Industry news

What Are the Key Benefits of Using Piezo Atomization Chips...

Introduction In the medical device industry, innovations in technology continually enhance treatment effectiveness, safety, and comfort for patients. One such breakthrough is the integration of piezo atomization chips, w...

-

Industry news

How Do Humidifier Discs Work to Maintain Optimal Humidity ...

Humidity plays a vital role in creating a comfortable living environment, particularly in regions where dry air can lead to health problems such as dry skin, respiratory issues, and discomfort. Humidifiers are essential ...

-

Industry news

How Do Medical Piezoelectric Ceramic Discs Benefit Patient...

Introduction to Medical Piezoelectric Ceramic Discs In recent years, advancements in non-invasive medical treatments have led to the introduction of innovative technologies that offer patients effective and minimally dis...

PI Lead Free Mesh Zeroing Chip Industry Knowledge Extension

How does the lead-free design of PI Lead Free Mesh Zeroing Chip in medical nebulizers improve safety and environmental protection?

In the field of medical nebulizers, technological innovation has always revolved around safety, environmental protection and efficiency. As a breakthrough technology, PI Lead Free Mesh Zeroing Chip is redefining the performance standards of medical nebulizers with its lead-free design and micro-mesh structure.

The lead-containing piezoelectric ceramic sheets used in traditional nebulizers may release harmful substances after being discarded, causing pollution to soil and water sources, and even affecting human health through the food chain. The lead-free design of PI Lead Free Mesh Zeroing Chip completely avoids this problem. As a global leading manufacturer of medical nebulizer-related products, Haining Saida Piezoelectric Ceramics Co., Ltd. has been committed to promoting the research and development and application of lead-free nebulization technology. Through innovative lead-free ceramic materials and high-precision manufacturing processes, PI Lead Free Mesh Zeroing Chip ensures that the nebulizer sheet will not cause secondary pollution to the environment while operating efficiently. This environmentally friendly design not only complies with increasingly stringent environmental regulations around the world, but also provides a more sustainable solution for the medical industry.

In terms of safety, the PI Lead Free Mesh Zeroing Chip also performs well. Its micro-grid design can control the median particle size (MMAD) of the atomized particles below 3.5μm, ensuring that the drug can accurately reach the deep lungs, thereby improving the treatment effect. In addition, the application of PI membrane technology further enhances the uniformity and stability of the atomized particles, making drug release more controllable and reducing drug waste or side effects caused by uneven particles. This high-precision atomization technology is particularly suitable for the treatment of respiratory diseases such as asthma, and can significantly improve patients' medication experience and treatment effects.

It is worth mentioning that the research and development and production of PI Lead Free Mesh Zeroing Chip are inseparable from advanced technical support. Since its establishment in 2011, Haining Saida Piezoelectric Ceramics Co., Ltd. has always been at the forefront of technological development, relying on a strong R&D team and advanced production equipment to continuously promote the innovation of ultrasonic piezoelectric ceramic technology. Its product line covers a variety of application scenarios from medical inhalation atomizers to industrial atomizers, and provides customers with a full range of technical support through PCBA drive solutions. The launch of PI Lead Free Mesh Zeroing Chip is the embodiment of this technological accumulation. It not only meets the medical industry's demand for efficient and precise atomization, but also implements the concept of environmental protection through lead-free design.

The lead-free design of PI Lead Free Mesh Zeroing Chip not only improves the safety and environmental protection of medical atomizers, but also provides a more efficient and precise solution for the treatment of respiratory diseases. As the world's attention to environmental protection and health continues to increase, this technology is expected to be more widely used in the medical field, bringing more value to patients and medical institutions. The companies behind the development of this technology have also set a benchmark for efficient, green and sustainable development for the industry through continuous technological innovation.

English

English 中文简体

中文简体