Power Generation/Heating Sensor Piezo Atomizer Manufacturers

The mechanism of piezoelectric ceramic power generation is mainly based on the piezoelectric effect. When the piezoelectric ceramics are by the external force, their internal positive and negative charge center will cause relative displacement, thus generating a potential difference, that is, piezoelectric voltage. This effect makes the piezoelectric ceramic convert mechanical energy into electrical energy. Specifically, when the external force compression piezoelectric ceramics, the crystal structure inside the ceramic will be deformed, resulting in the separation of positive and negative charges, which in turn generates a voltage at both ends of the ceramic. Conversely, when the external force disappears, the crystal structure inside the ceramic restores its original state, the charge is rebalanced, and the voltage disappear. Utilizing this property, piezoelectric ceramics can be widely used in energy harvesting, sensors, and actuators. In energy harvesting, piezoelectric ceramics can effectively convert mechanical vibration and pressure changes in the environment into electrical energy to power small electronic devices, such as wireless sensor network nodes and wearable devices. This type of energy collection has the advantages of being reen and sustainable, which can reduce the dependence on traditional power supply, and reduce energy consumption and environmental pollution.

In the field of sensors, the piezoelectric effect of piezoelectric ceramics enables them to sensitively sense external mechanical stimuli, such as pressure, vibration, acceleration, etc., and convert these physical quantities into electrical signals for output. Therefore, piezoelectric ceramic sensors are characterized by fast response speed, high sensitivity, good stability, etc., and are widely used in measurement, control, monitoring, and other systems.

In addition, piezoelectric ceramics also have an inverse piezoelectric effect, that is, under the action of the electric field can produce deformation. This characteristic makes piezoelectric ceramics in the field of drive also have a wide range of applications. By controlling the size and direction of the electric field, the deformation of piezoelectric ceramics can be precisely controlled, thus realizing precise displacement and force output. This kind of driver has the advantages of simple structure, fast response speed, high control accuracy, etc., and plays an important role in the field of micro-displacement control and precision machining.

In summary, the mechanism of piezoelectric ceramic power generation is based on the piezoelectric effect, and this characteristic makes it have a wide range of application prospects in the field of energy collection, sensors, and actuators. With the continuous development of science and technology, the performance of piezoelectric ceramics will continue to improve, and its application areas will be further expanded!

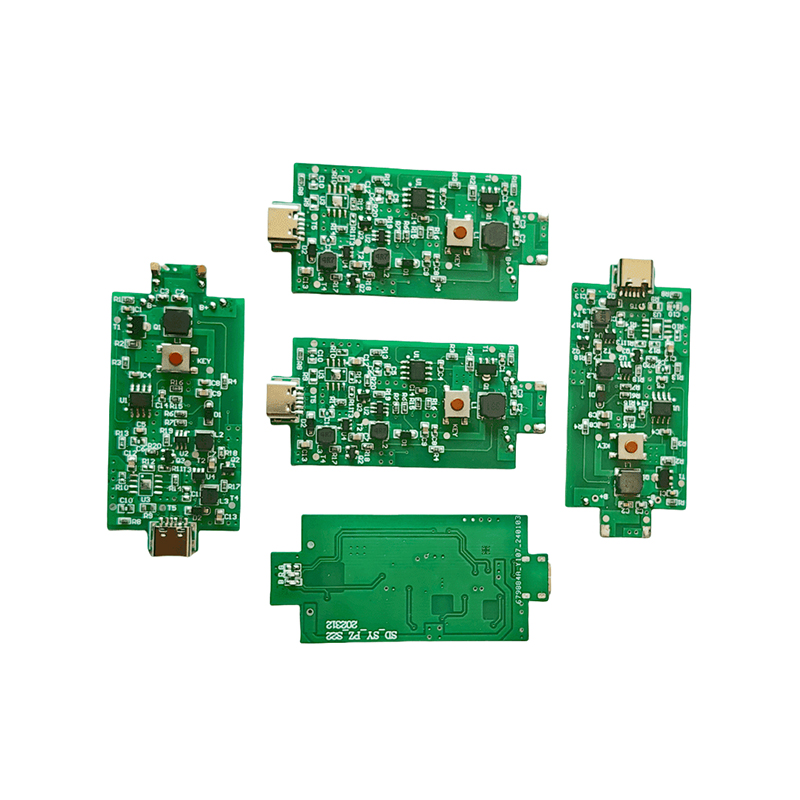

Saida Piezoelectric is a globally renowned technology-based enterprise specializing in the production and manufacturing of medical atomization related products, we are China Power Generation/Heating Sensor Piezo Atomizer Manufacturers and Custom OEM/ODM Power Generation/Heating Sensor Piezo Atomizer Company, We have been committed to the innovation, research and development, and promotion of ultrasonic piezoelectric ceramics, lead-free atomization products, electronic components, and related PCBA design solutions. Our goal is to improve people's quality of life through technology, and achieve a more efficient, green, and sustainable future for society.

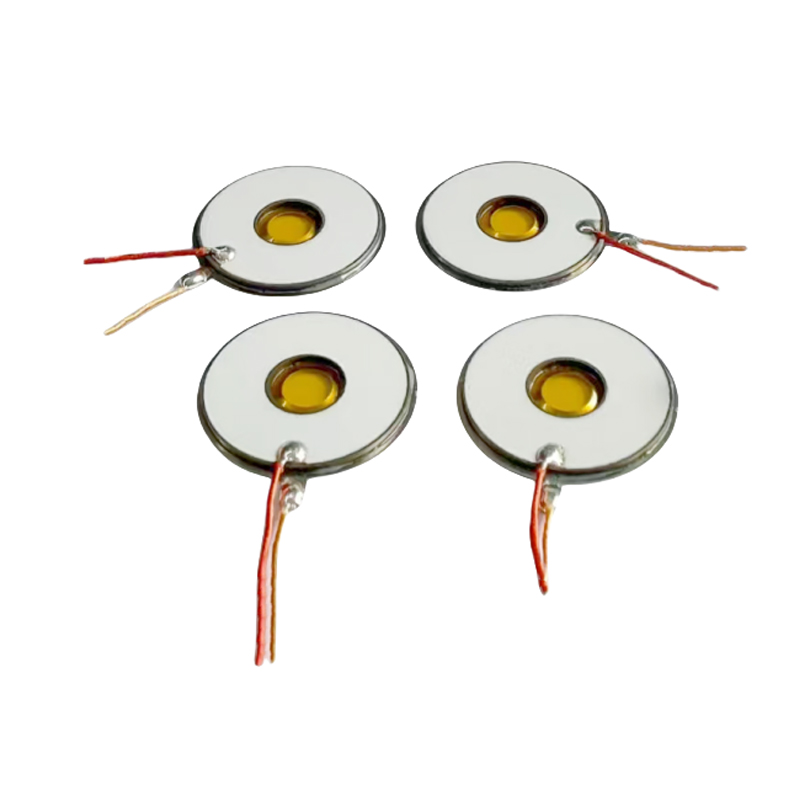

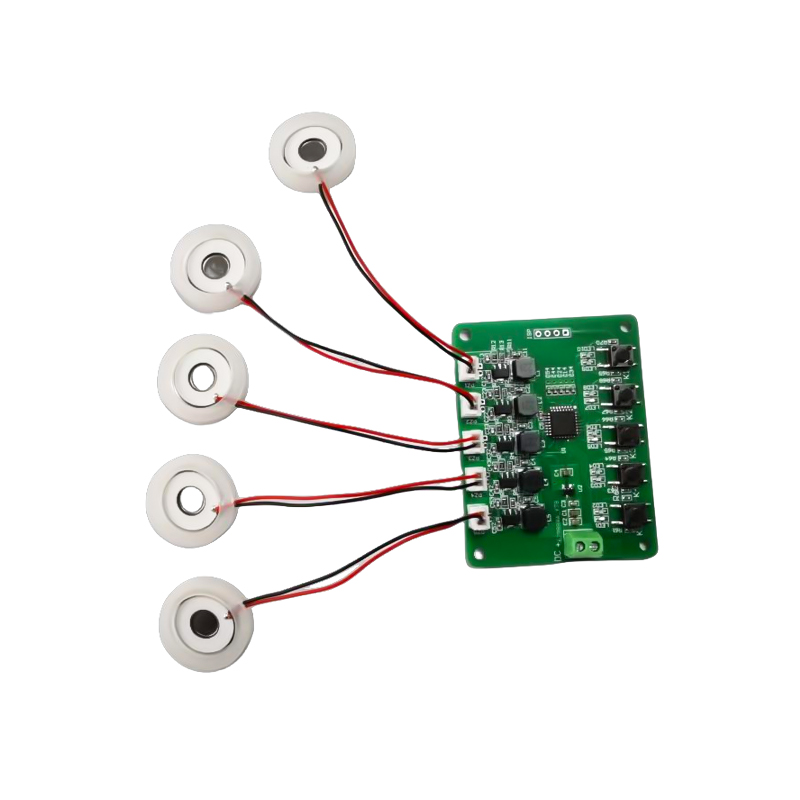

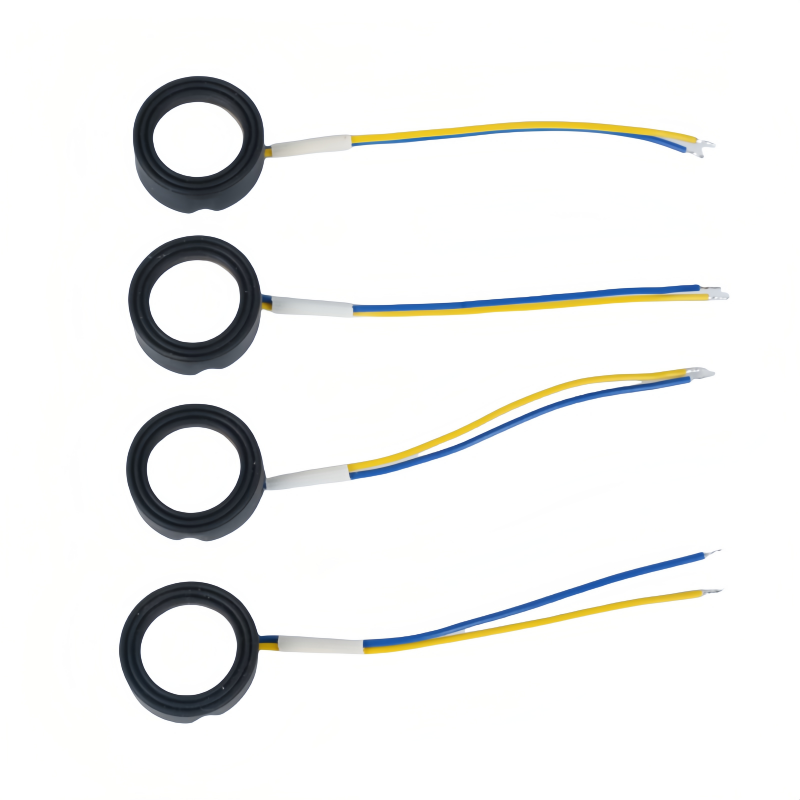

Since its establishment in April 2011, the company has been at the forefront of technological development, with an outstanding research and development team, advanced production and manufacturing equipment, and precision testing equipment. We cover a wide range of ultrasonic atomization products in our professional field, including lead based and lead-free medical inhalable atomization tablets, humidifier atomization tablets, essential oil atomization tablets, industrial atomization tablets, as well as sensing products related to ultrasonic piezoelectric and PCBA driving solutions. We not only focus on in-depth technological research and development, but also actively apply technological achievements to practical life, so that technological products can truly serve and benefit society, making the world more exciting and beautiful.

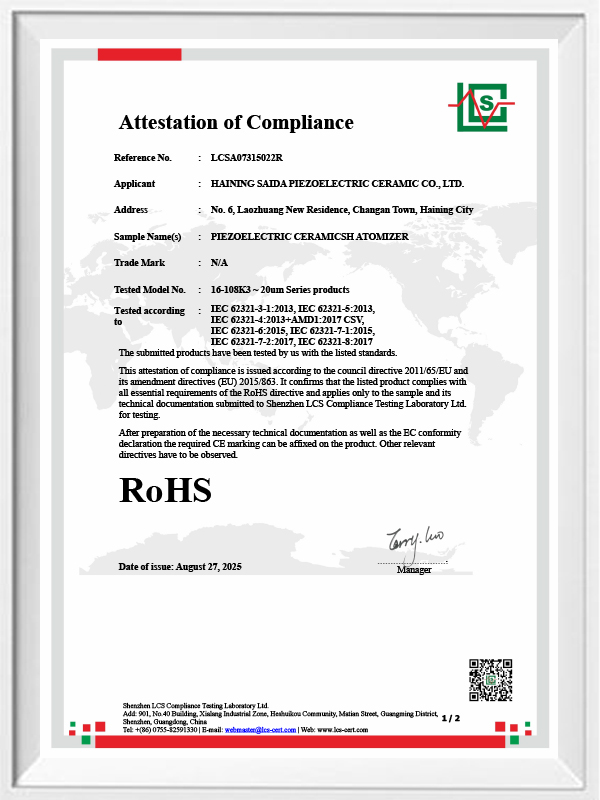

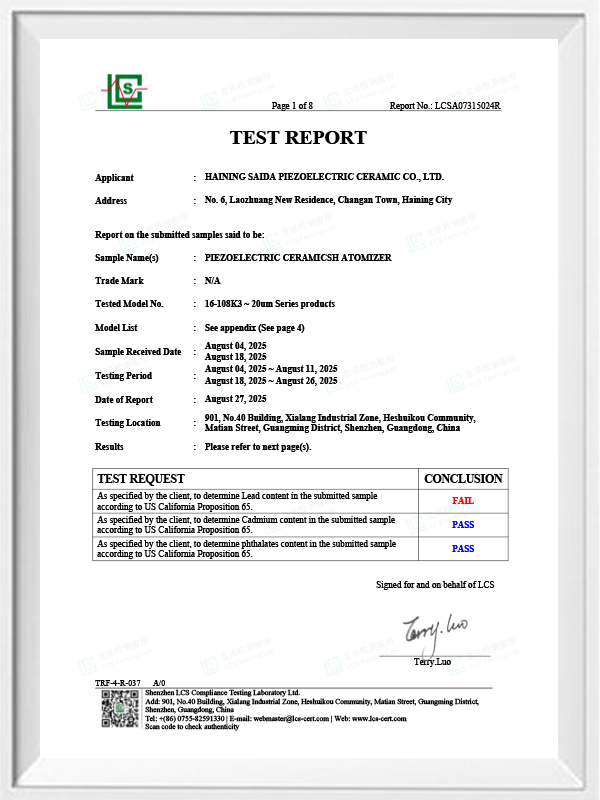

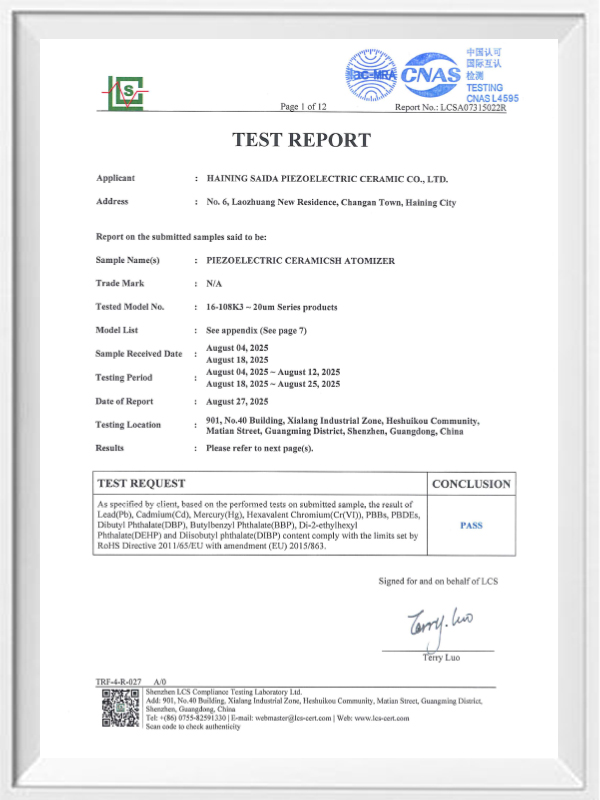

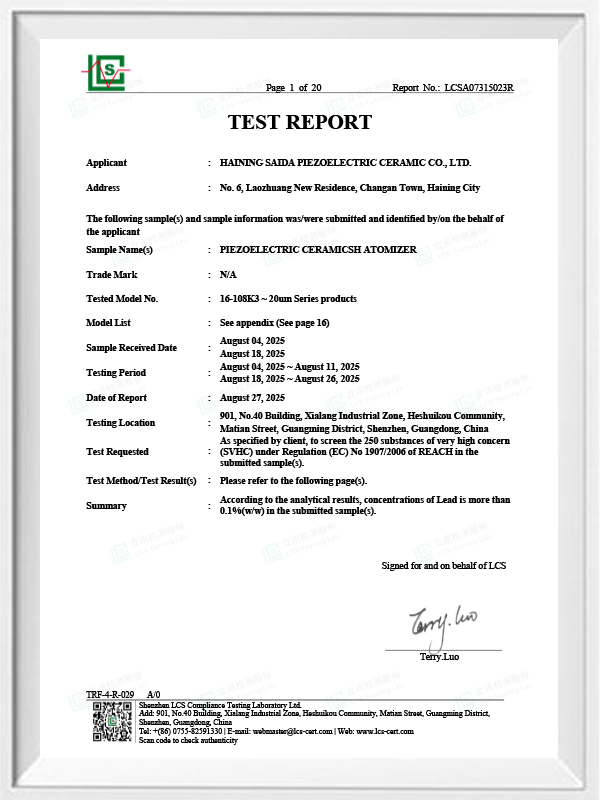

Certification

Our company's medical inhalable piezoelectric atomization series products have all passed the certifications required for export standards. They include ROHS certification, ISO9001 quality system certification, health system certification GB/T45001-2020/ISO 45001:2018, GB/T28001-2001 idt OHSAS18001:1999 Occupational Health and Safety Certification, environmental system certification GB/T24001-2016/ISO 14001:2015, California Proposition 65, REACH, and the medical atomization products have also been certified by the U.S. FDA.

news

-

Industry news

What Are the Key Benefits of Using PCB Medical Piezo Atomi...

Introduction In recent years, advancements in medical technology have led to innovations that promise improved treatment options, faster recovery times, and better overall patient outcomes. One such innovation is the PCB...

-

Industry news

How Do PCB Medical Piezo Atomizer Discs Contribute to the ...

Introduction The rapid advancements in non-invasive medical treatments have significantly reshaped healthcare practices, enabling more efficient and patient-friendly approaches to diagnostics and therapies. Among these i...

-

Industry news

How Do Piezo Atomization Chips Improve the Efficiency of S...

Introduction In the modern industrial landscape, spraying systems are crucial components across a wide array of applications, including manufacturing, agriculture, and healthcare. Efficient atomization in these systems i...

Power Generation/Heating Sensor Piezo Atomizer Industry Knowledge Extension

What special processes are used to optimize the piezoelectric properties and mechanical strength of the material during the processing of the piezo atomizer disc of the power generation/heating sensor?

1. Material selection and pretreatment

Before the processing begins, it is the basis to select the appropriate piezoelectric ceramic material. High-quality piezoelectric ceramic materials should have high piezoelectric constants, low dielectric losses and good mechanical properties.

In the material pretreatment stage, the piezoelectric ceramics may need to be sintered, polarized and other treatments. The sintering process can optimize the microstructure of the ceramics, improve their density and mechanical strength; while the polarization process is the key step to enable the piezoelectric ceramics to obtain piezoelectric properties. By precisely controlling the conditions of sintering and polarization, the performance of piezoelectric ceramics can be significantly improved.

2. Special processes to optimize piezoelectric performance

In the processing of piezoelectric ceramic discs, precision molding and cutting are the key to ensuring product accuracy. The use of advanced molding technology and high-precision cutting equipment, such as automatic laser drilling machines and pneumatic embossing machines, ensures that each disc can achieve extremely high dimensional accuracy and shape accuracy. This not only helps to improve the piezoelectric performance of the product, but also reduces the accumulation of errors in subsequent processing.

After initial forming and cutting, the piezoelectric ceramic discs are also finely ground and polished. This process can further remove surface defects and improve surface finish, thereby improving piezoelectric performance.

For some complex application scenarios, such as power generation sensors and piezo atomizers, piezoelectric ceramics with multilayer structures may be required. This design can achieve specific performance requirements by superimposing piezoelectric ceramic layers with different performances. Haining Saida Piezoelectric Ceramics Co., Ltd. has accumulated rich experience in multilayer structure design and can customize the optimal number of layers and interlayer connection methods according to customer requirements, thereby maximizing piezoelectric performance while ensuring mechanical strength.

High-temperature annealing and heat treatment are important means to optimize the performance of piezoelectric ceramics. By precisely controlling the annealing temperature and holding time, the residual stress inside the ceramic can be further eliminated, the crystal structure can be optimized, and the piezoelectric constant and mechanical strength can be improved.

3. Special process to optimize mechanical strength

In the design of piezoelectric ceramic discs, their mechanical strength can be enhanced through reasonable structural design. For example, adding reinforcing ribs to the edge of the disc or using other forms of reinforcement structures can effectively improve the bending strength and impact resistance of the disc.

Surface coating can not only improve the corrosion resistance of piezoelectric ceramics, but also enhance their mechanical strength to a certain extent. Using advanced coating technology, a uniform and dense protective layer is coated on the surface of piezoelectric ceramics, which effectively prevents the external environment from eroding the ceramics. The coating can also play a role in lubrication and friction reduction, which helps to extend the service life of the product.

In some high-end applications, piezoelectric ceramics may need to be compounded with other materials (such as metals, polymer materials, etc.) to enhance their mechanical properties. Haining Saida Piezoelectric Ceramics Co., Ltd. has in-depth research and exploration in composite reinforcement technology and can provide customized solutions according to customer requirements. Through reasonable material selection and structural design, the perfect combination of piezoelectric ceramics and composite materials can be achieved, thereby significantly improving mechanical strength while ensuring piezoelectric performance.

4. Quality Control and Inspection

During the processing process, quality control and inspection are key links to ensure product performance. Haining Saida Piezoelectric Ceramics Co., Ltd. is well aware of this, so it will conduct corresponding inspections after each process. For the final product, the company will conduct 99.99% full inspection according to customer requirements and international standards to ensure that each product can achieve the best performance state. In addition, the company also has sophisticated production equipment and complete testing equipment, such as tensile testing machines, ultrasonic impedance analyzers and image measuring instruments, which can monitor and evaluate the performance parameters and mechanical strength of products in real time.

English

English 中文简体

中文简体