Ultrasonic Atomizing Transducer Manufacturers

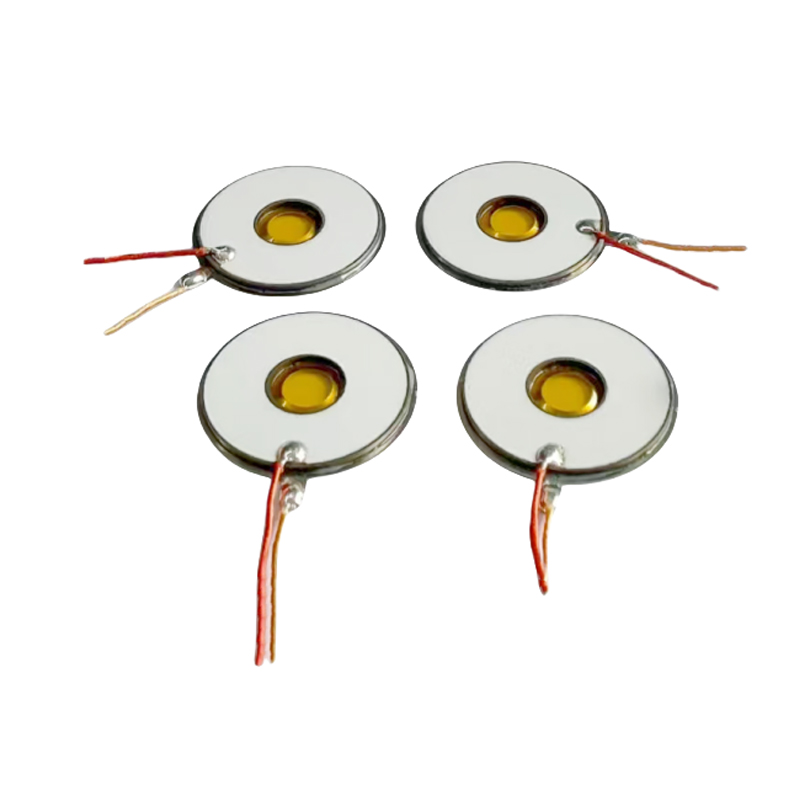

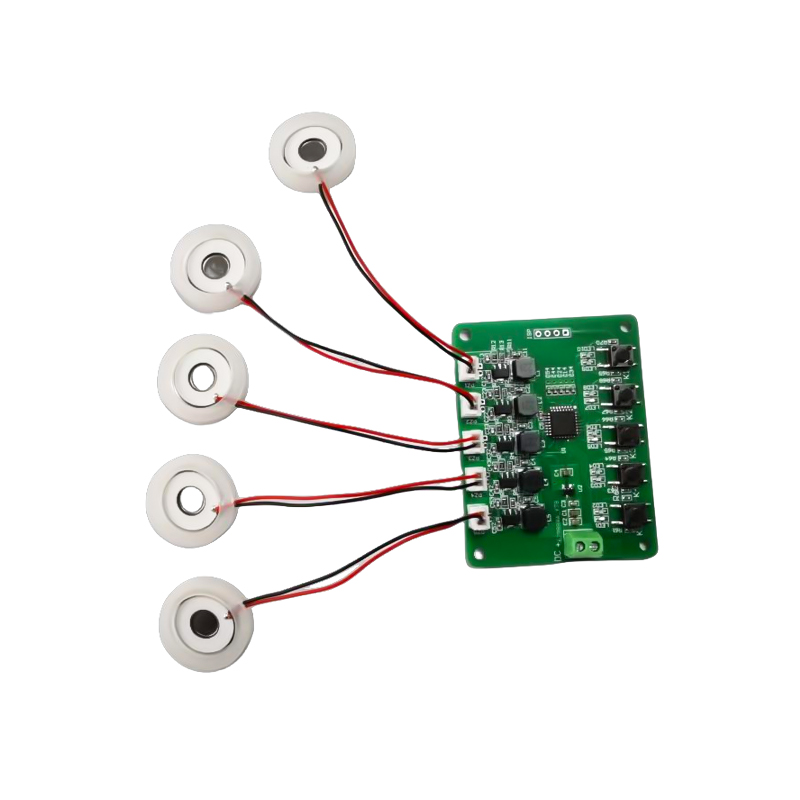

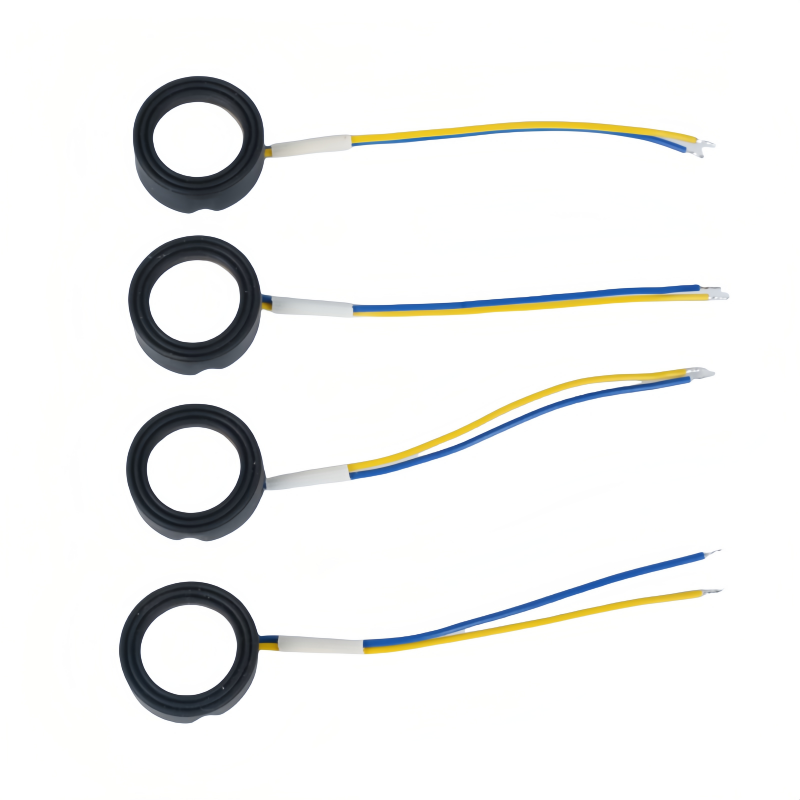

Ultrasonic cosmetic wafers and transducers are made of piezoelectric ceramics. Their operation principle is based on the piezoelectric effect, whereby ultrasonic waves are generated by applying a voltage that causes the material to vibrate. Ultrasonic transducers are designed with precision and materials are carefully selected to ensure that they are capable of emitting ultrasonic waves of specific frequencies and intensities to meet the needs of different applications. In addition, ultrasonic transducers have good durability and reliability, and can maintain stable performance over a long period of time. With high sensitivity and stability, it can respond quickly to acoustic signals in different media. It is made of high-quality materials with good abrasion and corrosion resistance, ensuring stable work for a long time. In addition, the ultrasonic transducer wafer has a compact design and is easy to install and maintain. It can be widely used in ultrasonic cleaning, ultrasonic welding, ultrasonic ranging, etc., providing efficient and reliable acoustic wave conversion solutions for various industrial applications.

Piezoelectric ceramics are functional materials that can convert mechanical and electrical energy into each other. When subjected to mechanical pressure, they generate an electric charge, a phenomenon known as the positive piezoelectric effect; conversely, when an electric field is applied, they deform, a phenomenon known as the inverse piezoelectric effect.

Piezoelectric ceramics are widely used in sensors, actuators, ultrasonic generators, energy harvesters and other fields. For example, sensors, can detect small pressure changes and convert them into electrical signals; actuators can convert electrical signals into precise mechanical movements. Due to their unique physical properties, piezoelectric ceramics play an important role in precision control and high-accuracy measurement equipment. Ultrasonic piezoelectric ceramics have high sensitivity and stability, and can efficiently convert electrical energy into acoustic and kinetic energy, which is widely used in medical imaging, non-destructive testing, distance measurement, and other fields.

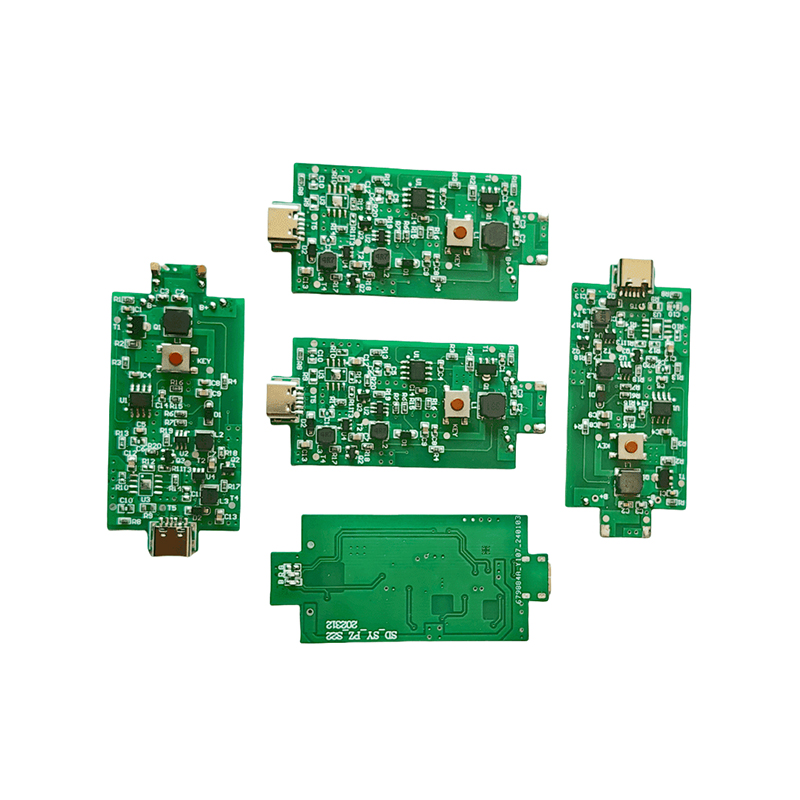

Saida Piezoelectric is a globally renowned technology-based enterprise specializing in the production and manufacturing of medical atomization related products, we are China Ultrasonic Atomizing Transducer Manufacturers and Custom OEM/ODM Ultrasonic Atomizing Transducer Company, We have been committed to the innovation, research and development, and promotion of ultrasonic piezoelectric ceramics, lead-free atomization products, electronic components, and related PCBA design solutions. Our goal is to improve people's quality of life through technology, and achieve a more efficient, green, and sustainable future for society.

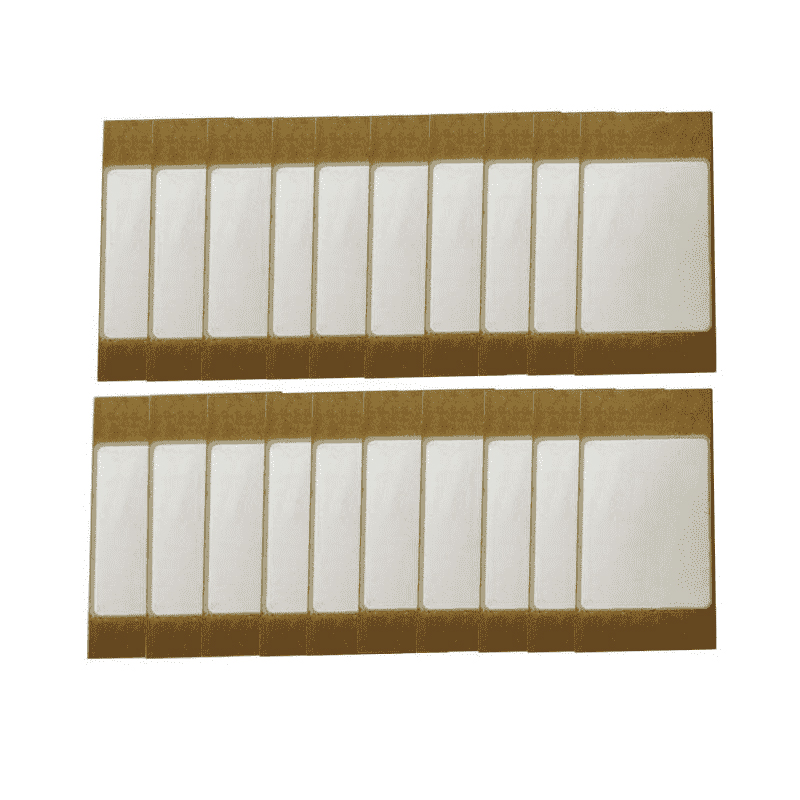

Since its establishment in April 2011, the company has been at the forefront of technological development, with an outstanding research and development team, advanced production and manufacturing equipment, and precision testing equipment. We cover a wide range of ultrasonic atomization products in our professional field, including lead based and lead-free medical inhalable atomization tablets, humidifier atomization tablets, essential oil atomization tablets, industrial atomization tablets, as well as sensing products related to ultrasonic piezoelectric and PCBA driving solutions. We not only focus on in-depth technological research and development, but also actively apply technological achievements to practical life, so that technological products can truly serve and benefit society, making the world more exciting and beautiful.

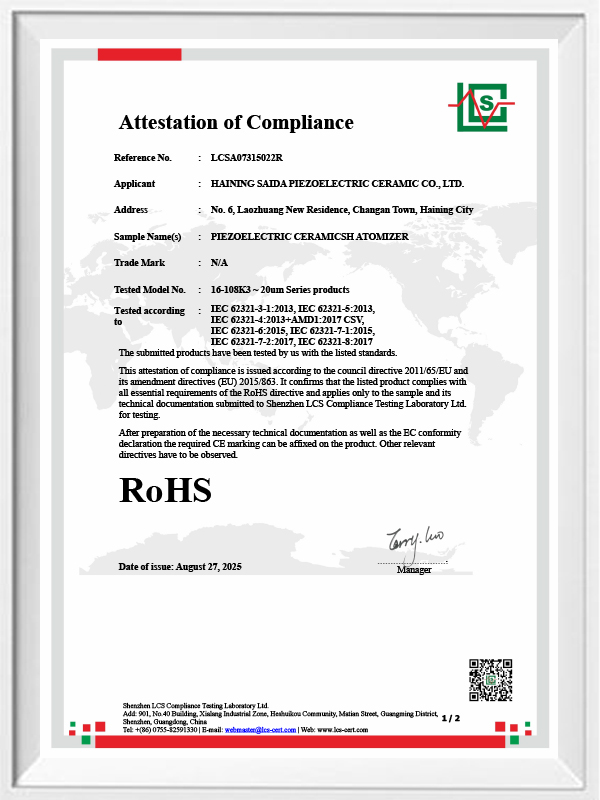

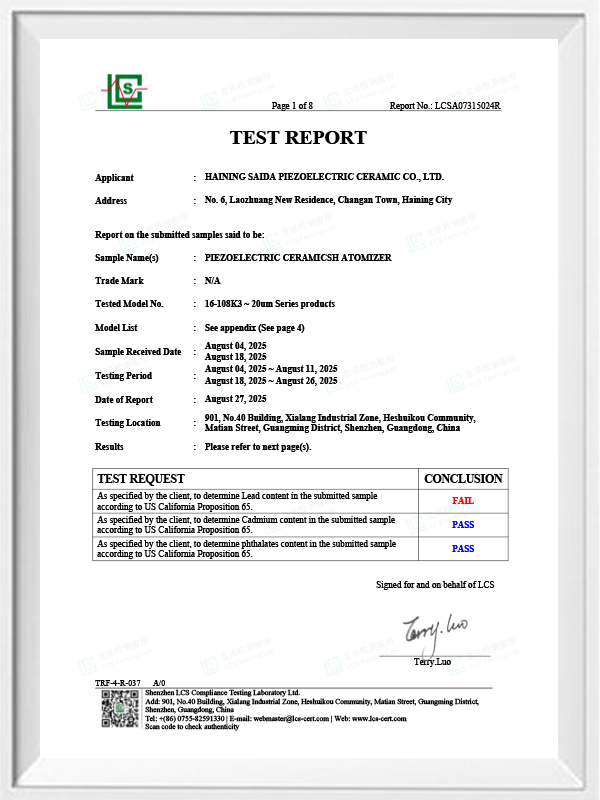

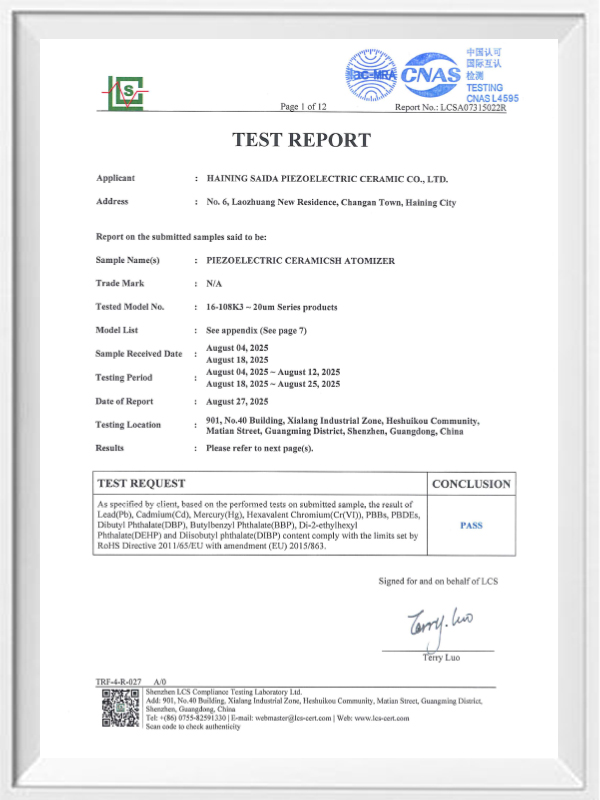

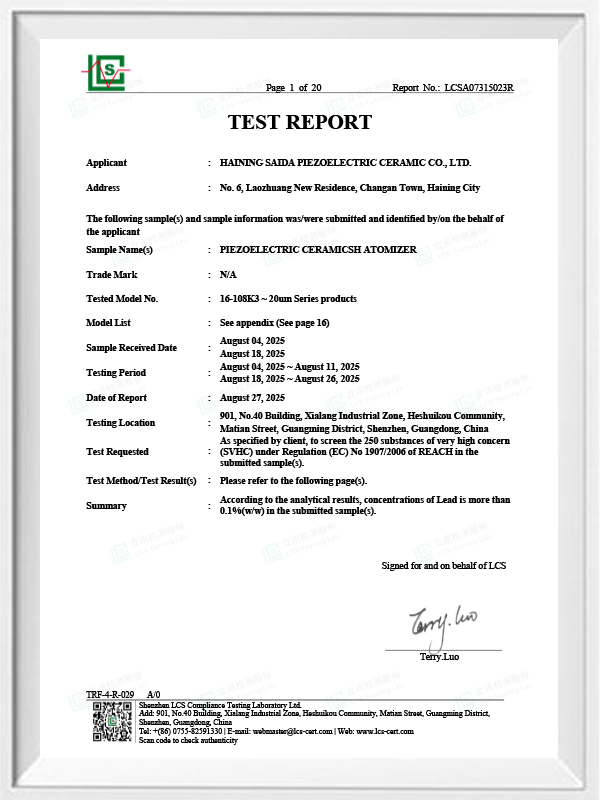

Certification

Our company's medical inhalable piezoelectric atomization series products have all passed the certifications required for export standards. They include ROHS certification, ISO9001 quality system certification, health system certification GB/T45001-2020/ISO 45001:2018, GB/T28001-2001 idt OHSAS18001:1999 Occupational Health and Safety Certification, environmental system certification GB/T24001-2016/ISO 14001:2015, California Proposition 65, REACH, and the medical atomization products have also been certified by the U.S. FDA.

news

-

Industry news

What Are the Key Benefits of Using Piezo Atomization Chips...

Introduction In the medical device industry, innovations in technology continually enhance treatment effectiveness, safety, and comfort for patients. One such breakthrough is the integration of piezo atomization chips, w...

-

Industry news

How Do Humidifier Discs Work to Maintain Optimal Humidity ...

Humidity plays a vital role in creating a comfortable living environment, particularly in regions where dry air can lead to health problems such as dry skin, respiratory issues, and discomfort. Humidifiers are essential ...

-

Industry news

How Do Medical Piezoelectric Ceramic Discs Benefit Patient...

Introduction to Medical Piezoelectric Ceramic Discs In recent years, advancements in non-invasive medical treatments have led to the introduction of innovative technologies that offer patients effective and minimally dis...

Ultrasonic Atomizing Transducer Industry Knowledge Extension

How to ensure that ultrasonic atomization transducers emit ultrasound waves of a specific frequency and intensity

Ultrasonic atomization transducers play a vital role in the field of modern science and technology, especially in beauty, medical treatment, industrial cleaning and environmental protection. The core component of this type of transducer is piezoelectric ceramics, a material with special physical properties that can convert electrical energy into mechanical vibration energy through the piezoelectric effect, thereby generating ultrasound waves. However, ensuring that ultrasonic atomization transducers can emit ultrasound waves of a specific frequency and intensity requires precise design and high-quality material selection.

Piezoelectric ceramics: the cornerstone of ultrasound

The heart of the ultrasonic atomization transducer is the piezoelectric ceramic chip. Piezoelectric ceramics are materials that can deform under the action of an electric field or generate electric charges under mechanical stress. This unique property makes piezoelectric ceramics an ideal choice for manufacturing ultrasonic transducers. When voltage is applied to a piezoelectric ceramic, it begins to vibrate, and the frequency and intensity of the vibration depend on the frequency and amplitude of the applied voltage. By precisely controlling the voltage signal, it can be ensured that the piezoelectric ceramic emits ultrasound waves of a specific frequency and intensity.

Precision Design and Material Selection

In order to manufacture transducers that can emit ultrasound waves of specific frequencies and intensities, precision design and high-quality material selection are essential. The design team will comprehensively consider the geometry, size, thickness, and electrode layout of the piezoelectric ceramics to optimize the performance of the transducer. In addition, the propagation and absorption characteristics of different materials for ultrasound waves will also affect the efficiency of the transducer. Therefore, choosing the right piezoelectric ceramic formula, as well as the right electrode material and coating, is also a key factor in ensuring the stability of the transducer performance.

In the design of ultrasonic atomization transducers, it is also necessary to consider the propagation characteristics of sound waves in different media. For example, in beauty equipment, ultrasound waves need to be able to penetrate the skin and act on the target layer, while in industrial cleaning, ultrasound waves need to be able to generate enough impact force to remove stains. These different application scenarios require transducers with different frequency and intensity characteristics. Therefore, designers need to meet the needs of specific applications by adjusting the vibration mode and frequency response of piezoelectric ceramics and optimizing the overall structure of the transducer.

Stability and Durability

In addition to precise control of frequency and intensity, ultrasonic atomization transducers also need to have stability and durability. During long-term operation, piezoelectric ceramics may be affected by thermal effects, mechanical fatigue and environmental factors such as humidity and temperature, causing their performance to deteriorate. In order to ensure that the transducer can work continuously and stably, manufacturers use high-quality piezoelectric ceramic materials and improve their durability through special process treatment. In addition, through strict testing and quality control, it can be ensured that each transducer meets the specified performance standards before leaving the factory.

As a leader in ultrasonic piezoelectric ceramics and related technologies, Haining Saida Piezoelectric Ceramics Co., Ltd. has been committed to the innovation, research and development and promotion of ultrasonic piezoelectric ceramics, lead-free atomization products, electronic components and related PCBA design solutions. Our goal is to improve people's quality of life through technology and achieve a more efficient, green and sustainable future for society. To achieve this goal, we continue to invest in R&D resources, optimize product performance, improve production efficiency, and ensure that our ultrasonic atomization transducers can emit ultrasonic waves with precisely controlled frequency and intensity to meet the needs of various application scenarios.

Our ultrasonic atomization transducers use precision-designed piezoelectric ceramic chips, combined with high-quality materials and advanced manufacturing processes, to ensure their stability and durability during long-term use. At the same time, we also provide customized solutions to meet customers' specific needs for ultrasonic waves of different frequencies and intensities. Through cooperation with us, customers can obtain efficient, reliable and environmentally friendly ultrasonic atomization technology to bring excellent performance and competitiveness to their products.

English

English 中文简体

中文简体