Ultrasonic High-frequency Piezo Atomizer Disc Manufacturers

Ultrasonic atomizer is a device that uses the principle of ultrasonic vibration (energy conversion) to convert liquid into tiny droplets. The working principle is the piezoelectric ceramics' unique piezoelectric properties of the decision, the atomization piece in the receipt of matching electric field signal excitation, will produce the corresponding oscillation frequency, through the role of high-frequency vibration of the liquid cavitation thrown away from the surface of the water to produce a kind of water mist particles, atomized with a large number of negative ions and small particles of molecules, can achieve an increase in ambient humidity, the role of fresh air.

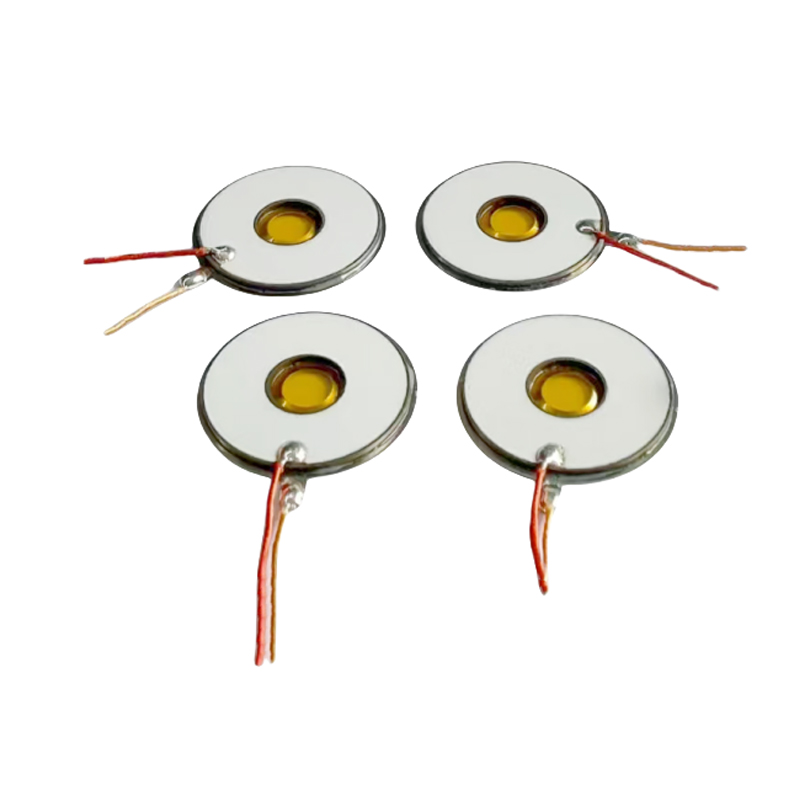

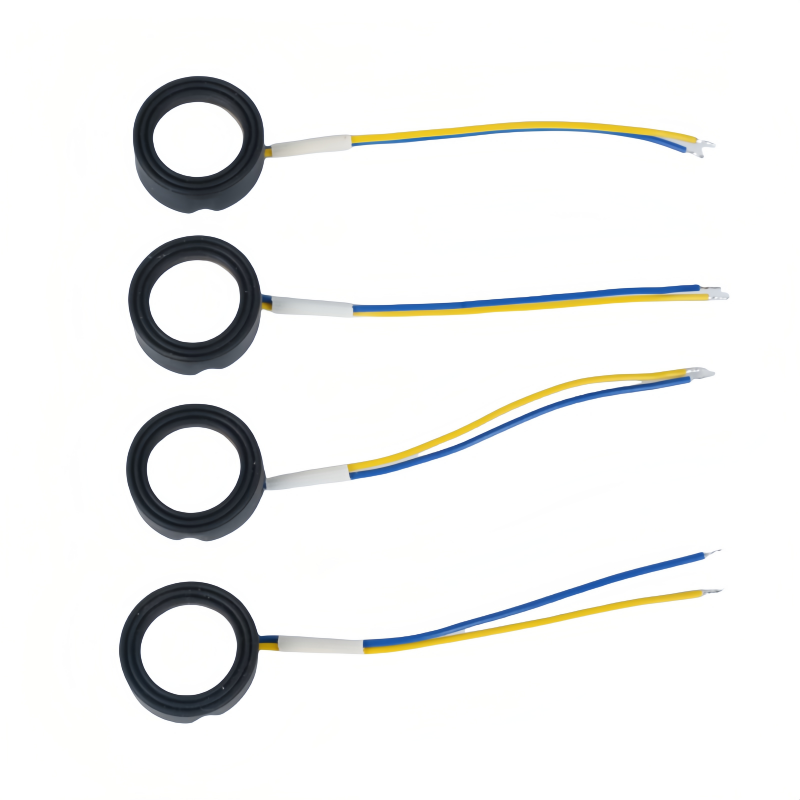

The surface of the atomizer is coated with vitreous enamel at a high temperature of 800 degrees to protect the silver electrodes of the piezoelectric sheet, increase the acid and alkali resistance and oxidation resistance of the atomizer, and increase the service life of the atomizer. Widely used in indoor humidifiers, air purifiers, medical nebulizer treatment, and beauty cars,e and other fields, but also suitable for warehouses, factories, humidification, disinfection, to create the atmosphere of humidification equipment. Fogging tablets are mainly used in industrial humidification, medical fogging, aromatherapy fogging, environmental humidification, garden fogging and other scenes.

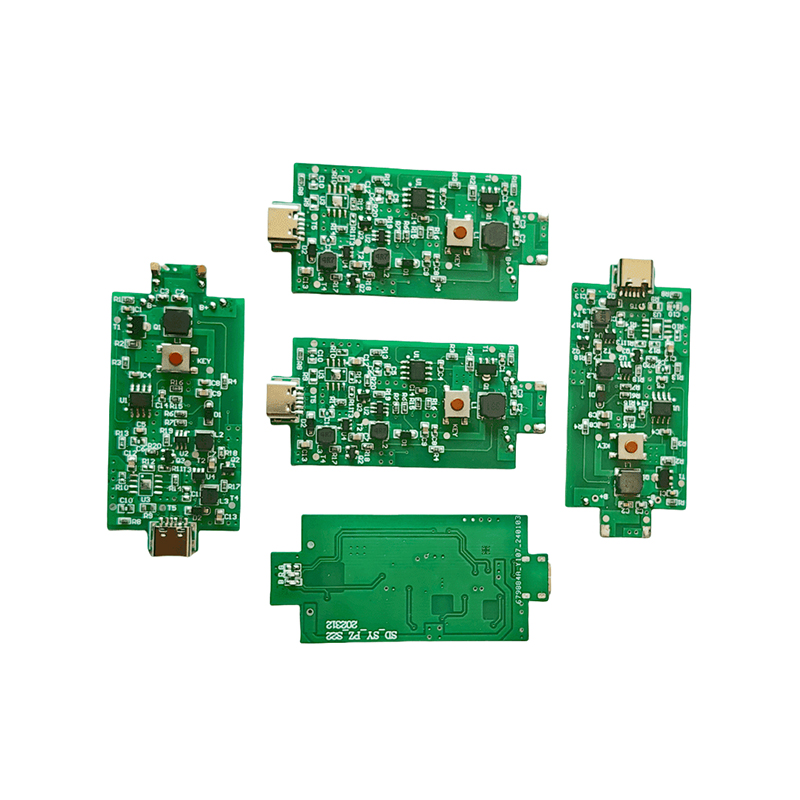

Saida Piezoelectric is a globally renowned technology-based enterprise specializing in the production and manufacturing of medical atomization related products, we are China Ultrasonic High-frequency Piezo Atomizer Disc Manufacturers and Custom Ultrasonic High-frequency Piezo Atomizer Disc Company, We have been committed to the innovation, research and development, and promotion of ultrasonic piezoelectric ceramics, lead-free atomization products, electronic components, and related PCBA design solutions. Our goal is to improve people's quality of life through technology, and achieve a more efficient, green, and sustainable future for society.

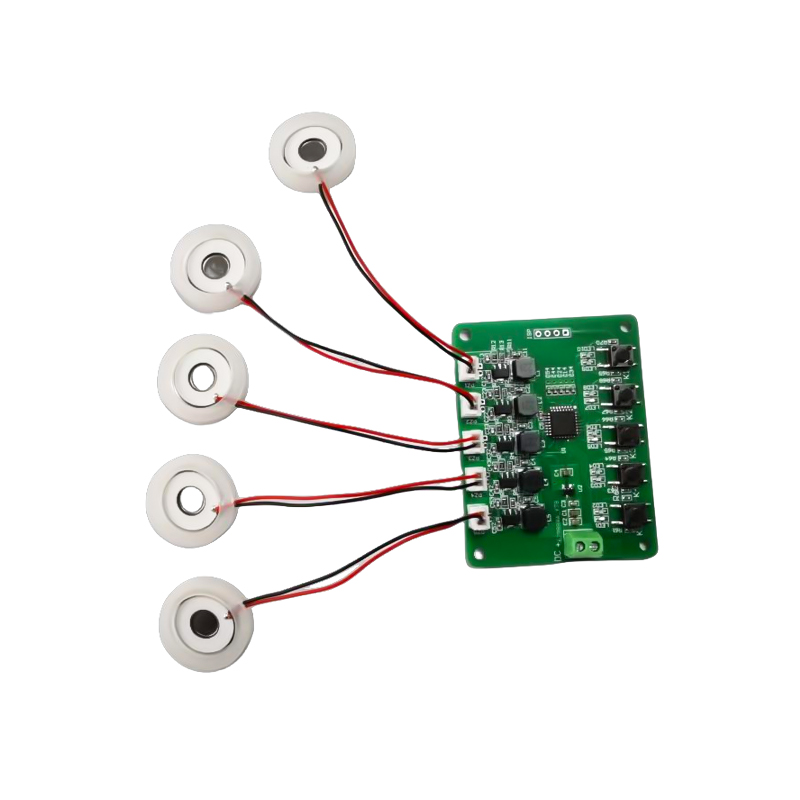

Since its establishment in April 2011, the company has been at the forefront of technological development, with an outstanding research and development team, advanced production and manufacturing equipment, and precision testing equipment. We cover a wide range of ultrasonic atomization products in our professional field, including lead based and lead-free medical inhalable atomization tablets, humidifier atomization tablets, essential oil atomization tablets, industrial atomization tablets, as well as sensing products related to ultrasonic piezoelectric and PCBA driving solutions. We not only focus on in-depth technological research and development, but also actively apply technological achievements to practical life, so that technological products can truly serve and benefit society, making the world more exciting and beautiful.

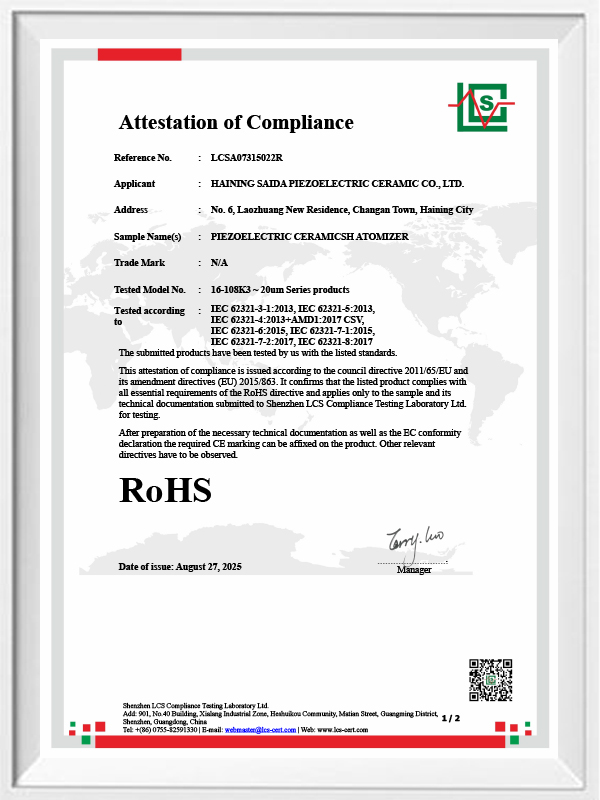

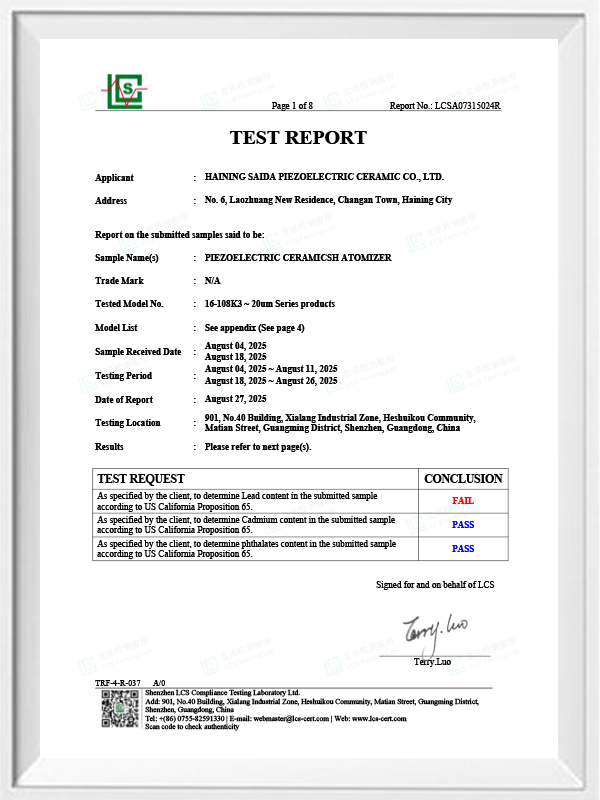

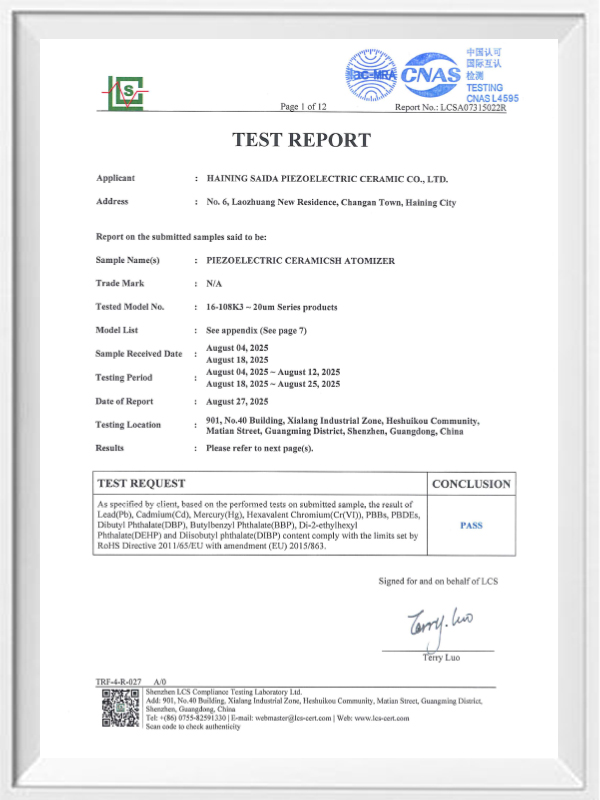

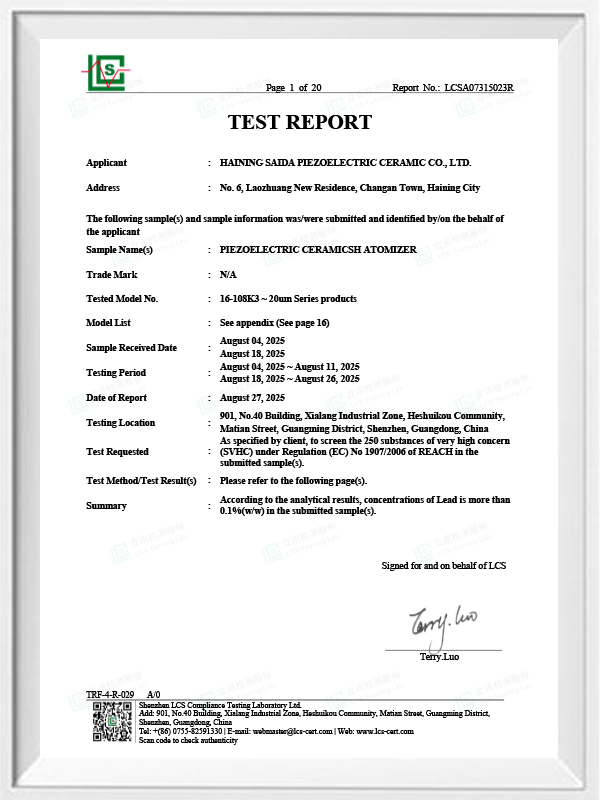

Certification

Our company's medical inhalable piezoelectric atomization series products have all passed the certifications required for export standards. They include ROHS certification, ISO9001 quality system certification, health system certification GB/T45001-2020/ISO 45001:2018, GB/T28001-2001 idt OHSAS18001:1999 Occupational Health and Safety Certification, environmental system certification GB/T24001-2016/ISO 14001:2015, California Proposition 65, REACH, and the medical atomization products have also been certified by the U.S. FDA.

news

-

Industry news

What Are the Key Benefits of Using Piezo Atomization Chips...

Introduction In the medical device industry, innovations in technology continually enhance treatment effectiveness, safety, and comfort for patients. One such breakthrough is the integration of piezo atomization chips, w...

-

Industry news

How Do Humidifier Discs Work to Maintain Optimal Humidity ...

Humidity plays a vital role in creating a comfortable living environment, particularly in regions where dry air can lead to health problems such as dry skin, respiratory issues, and discomfort. Humidifiers are essential ...

-

Industry news

How Do Medical Piezoelectric Ceramic Discs Benefit Patient...

Introduction to Medical Piezoelectric Ceramic Discs In recent years, advancements in non-invasive medical treatments have led to the introduction of innovative technologies that offer patients effective and minimally dis...

Ultrasonic High-frequency Piezo Atomizer Industry Knowledge Extension

How to ensure the alignment and precise placement of FPC flexible circuit boards, piezoelectric ceramics and conductive films during the assembly of ultrasonic high-frequency piezoelectric atomizers disc?

The assembly of ultrasonic high-frequency piezoelectric atomizers is a complex and delicate process, in which the alignment and precise placement of FPC (flexible printed circuit board) flexible circuit boards, piezoelectric ceramics and conductive films are key steps to ensure the performance of atomizers. The precise assembly of these components not only affects the working efficiency of the atomizer, but is also directly related to its service life and reliability. The following will discuss in detail how to ensure the alignment and precise placement of these key components during the assembly process.

1. Understanding of component characteristics and functions

Before starting assembly, it is crucial to have a deep understanding of the characteristics and functions of each component.

FPC flexible circuit board: FPC flexible circuit board has the characteristics of light weight, thin thickness and bendability, and can provide complex circuit connections in a limited space. In the atomizer, FPC is responsible for transmitting electrical signals to piezoelectric ceramics and is a bridge for electrical signal transmission.

Piezoelectric ceramics: Piezoelectric ceramics are the core components of ultrasonic atomizers and have piezoelectric effect, that is, they can generate mechanical vibrations under the action of an external electric field. This vibration is the power source of the atomization process, and its frequency and amplitude directly affect the atomization effect.

Conductive film: Conductive film is a conductive film used to establish an electrical connection between FPC and piezoelectric ceramics. It must have good conductivity, adhesion and environmental resistance to ensure stable transmission of electrical signals.

2. The importance of precise alignment

During the assembly process, the alignment of FPC, piezoelectric ceramics and conductive film is crucial. Any slight deviation may lead to poor transmission of electrical signals, which in turn affects the performance of the atomizer. For example, if the alignment of FPC and piezoelectric ceramics is inaccurate, it may cause delay or loss of electrical signal transmission; if the conductive film is not placed correctly, it may cause poor electrical connection and even cause a short circuit.

3. Alignment and placement methods

In order to ensure the alignment and precise placement of FPC flexible circuit boards, piezoelectric ceramics and conductive films, the following measures can be taken:

Use precision positioning tools: During the assembly process, use precision positioning tools (such as positioning pins, positioning fixtures, etc.) to ensure the accurate alignment of each component. These tools can fix the position of the components to prevent them from moving during the assembly process.

Use visual assistance system: Use visual assistance systems such as microscopes or high-precision cameras to monitor the alignment of components in real time. This can not only improve the accuracy of assembly, but also detect and correct alignment deviations in a timely manner.

Optimize the assembly process: Develop a detailed assembly process and clarify the operating requirements and precautions for each step. Through process optimization, reduce alignment deviations caused by human factors and improve assembly efficiency and accuracy.

Train operators: Provide professional training for operators to familiarize them with the characteristics, assembly processes and operating requirements of components. Ensure the accuracy and stability of the assembly process by improving the skill level of operators.

4. Application and curing of conductive adhesive film

The application and curing of conductive adhesive film are also key links to ensure component alignment and precise placement.

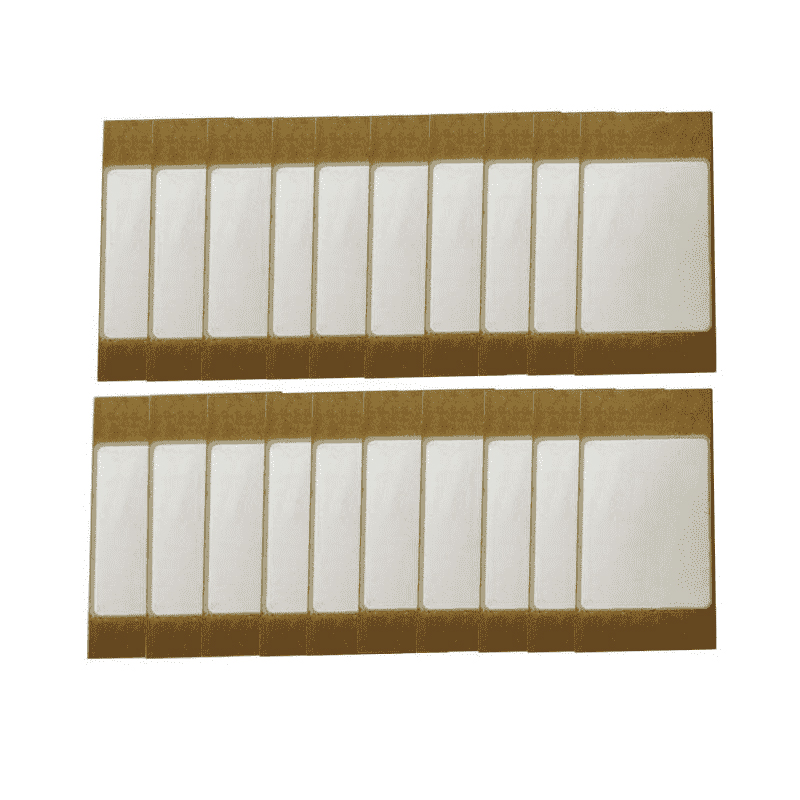

Film selection: Select a suitable conductive adhesive film based on the working environment and performance requirements of the atomizer. Consider the conductivity, adhesion, temperature resistance, humidity resistance and other factors of the film to ensure that it can meet long-term use requirements.

Film cutting and placement: Use precision cutting tools to cut the conductive film into the required shape and size, and then accurately place it between the FPC and the piezoelectric ceramic. During the placement process, ensure that the film fits tightly to the surface of the component without bubbles or wrinkles.

Film curing: The conductive film needs to go through a curing process after placement to exert its conductive properties. According to the curing conditions of the film (such as temperature, time, etc.), a reasonable curing process is formulated. During the curing process, the temperature and time must be strictly controlled to ensure that the film can be fully cured and achieve optimal performance.

English

English 中文简体

中文简体