ODM/OEM Piezo Atomizer Disc Manufacturers

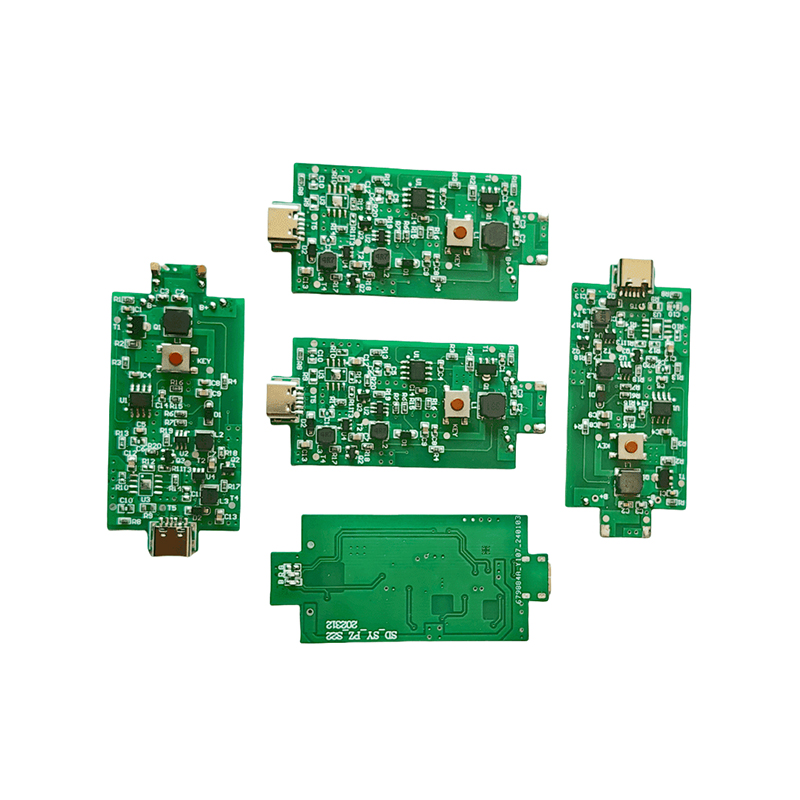

Saida Piezoelectric is a globally renowned technology-based enterprise specializing in the production and manufacturing of medical atomization related products, we are China ODM/OEM Piezo Atomizer Disc Manufacturers and Custom ODM/OEM Piezo Atomizer Disc Company, We have been committed to the innovation, research and development, and promotion of ultrasonic piezoelectric ceramics, lead-free atomization products, electronic components, and related PCBA design solutions. Our goal is to improve people's quality of life through technology, and achieve a more efficient, green, and sustainable future for society.

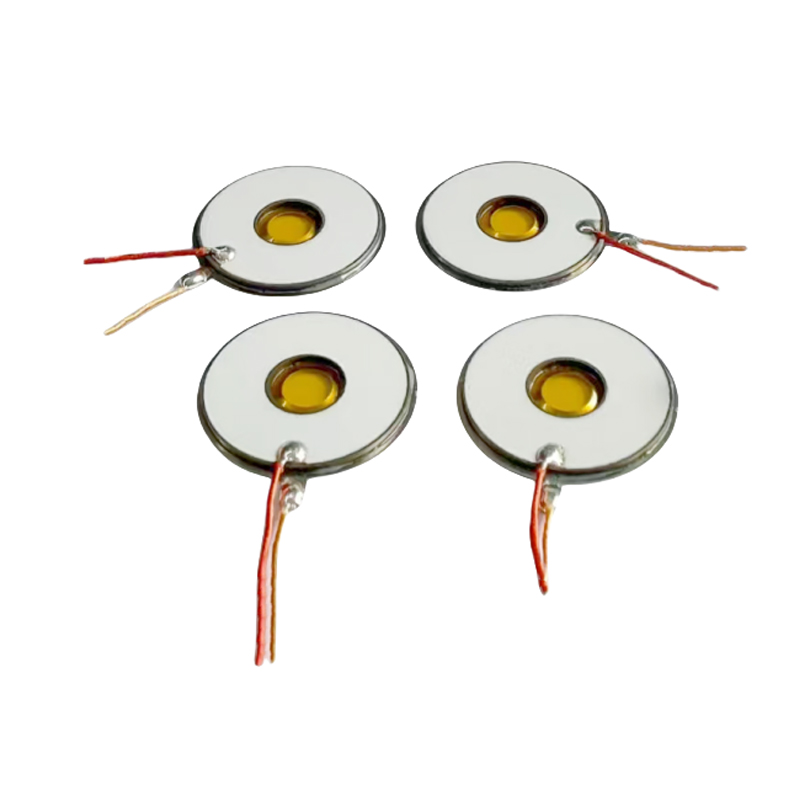

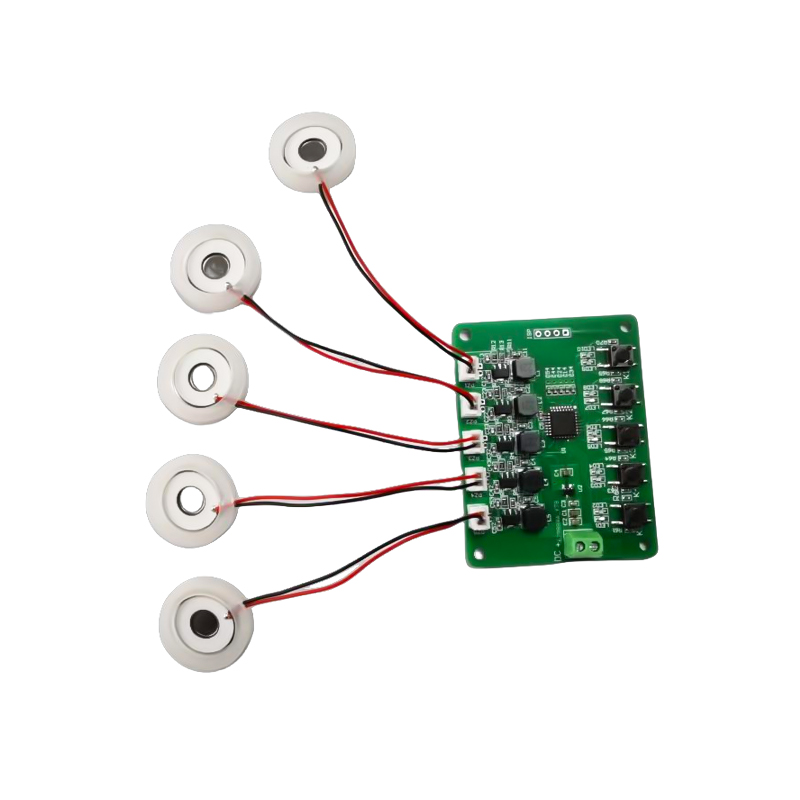

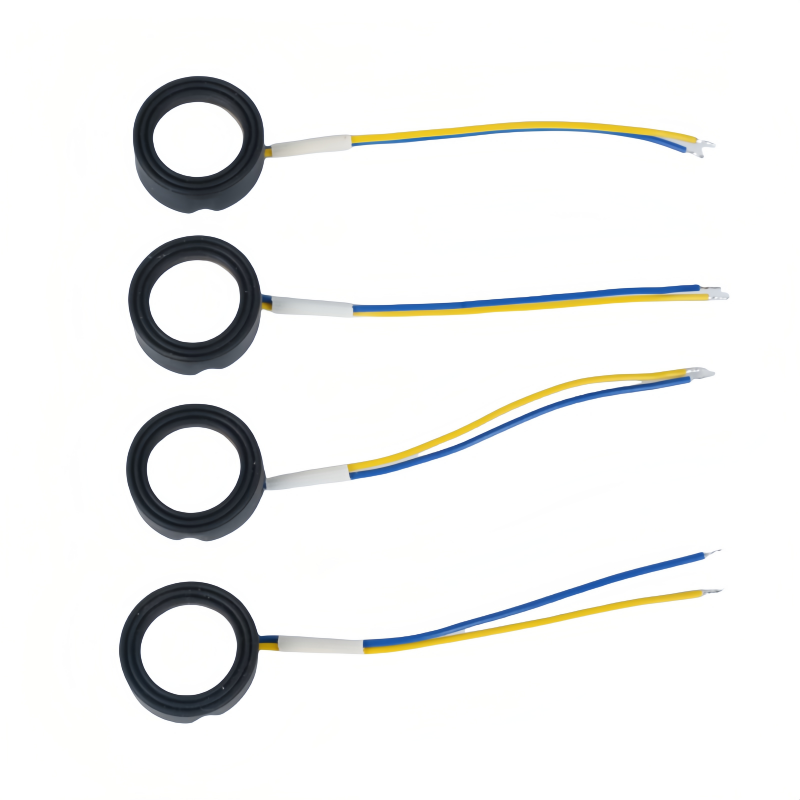

Since its establishment in April 2011, the company has been at the forefront of technological development, with an outstanding research and development team, advanced production and manufacturing equipment, and precision testing equipment. We cover a wide range of ultrasonic atomization products in our professional field, including lead based and lead-free medical inhalable atomization tablets, humidifier atomization tablets, essential oil atomization tablets, industrial atomization tablets, as well as sensing products related to ultrasonic piezoelectric and PCBA driving solutions. We not only focus on in-depth technological research and development, but also actively apply technological achievements to practical life, so that technological products can truly serve and benefit society, making the world more exciting and beautiful.

Certification

Our company's medical inhalable piezoelectric atomization series products have all passed the certifications required for export standards. They include ROHS certification, ISO9001 quality system certification, health system certification GB/T45001-2020/ISO 45001:2018, GB/T28001-2001 idt OHSAS18001:1999 Occupational Health and Safety Certification, environmental system certification GB/T24001-2016/ISO 14001:2015, California Proposition 65, REACH, and the medical atomization products have also been certified by the U.S. FDA.

news

-

Industry news

Material Selection and Manufacturing Processes for Medical...

As global medical technologies progress toward higher precision, miniaturization, and intelligent diagnostics, the medical piezoelectric ceramic disc has become a critical functional component across ultrasonic imaging s...

-

Industry news

How Does a Piezo Ceramic Atomizer Disc Improve Fine Mist D...

With the continuous growth in global demand for precise medical nebulization therapy, the core component of medical nebulizers—the medical mesh piezo atomizer disc—has become a focal point in the industry. As a key eleme...

-

Industry news

How Medical Piezoelectric Ceramic Discs Work: Principles, ...

The rapid advancement of medical electronics, diagnostic imaging, and minimally invasive treatment technologies has brought renewed attention to piezoelectric materials. Among them, the medical piezoelectric ceramic disc...

Piezo Atomizer Disc Industry Knowledge Extension

What are the key factors to consider in the design and manufacturing process of Piezo Atomizer Disc?

In the process of designing and manufacturing Piezo Atomizer Disc, Haining Saida Piezoelectric Ceramics Co., Ltd., as a world-renowned Piezo Atomizer Disc product manufacturer and customized ODM/OEM solution provider, will consider the following key factors:

1. Material selection and quality control

Piezoelectric ceramic material: The core of the Piezo Atomizer Disc is the piezoelectric ceramic material, and its performance directly affects the atomization effect and product life. Saida Piezoelectric focuses on the research and development and innovation of ultrasonic piezoelectric ceramics, and will give priority to high-performance and high-stability piezoelectric ceramic materials, such as PZT (lead zirconate titanate) or lead-free piezoelectric ceramics, to meet the environmental protection and performance requirements of different customers.

Material consistency: In large-scale production, ensuring the consistency of material batches is the key. The company uses a strict quality control system to ensure that the performance of each batch of piezoelectric ceramic materials is stable, thereby ensuring the reliability and consistency of the product.

2. Structural design and optimization

Atomization efficiency: When designing, we will focus on how to optimize the structure of the Piezo Atomizer Disc to improve the atomization efficiency. For example, by adjusting the size, shape and electrode distribution of piezoelectric ceramics, we can achieve finer atomized particles and higher atomization flow.

Frequency matching: The operating frequency of the Piezo Atomizer Disc is crucial to its performance. Saida Piezoelectric uses precise structural design to ensure that the operating frequency of the atomizer matches the drive circuit to achieve the best atomization effect.

Durability and reliability: Considering the long-term use needs of the product, the design will strengthen the structural strength of the atomizer, reduce the impact of mechanical stress on piezoelectric ceramics, and extend the service life of the product.

3. Environmental protection and sustainability

Lead-free trend: With the improvement of environmental protection requirements, Saida Piezoelectric actively develops and promotes lead-free atomization products. Lead-free piezoelectric ceramics not only meet environmental protection standards, but also meet the needs of high-end markets such as medical and beauty for green products.

Green production: During the manufacturing process, the company focuses on energy conservation and emission reduction and resource recycling, and achieves sustainable development by optimizing production processes, reducing energy consumption and waste emissions.

4. Customization and compatibility

ODM/OEM solutions: As a professional ODM/OEM manufacturer, Saida Piezoelectric is able to provide customized Piezo Atomizer Disc designs based on the specific needs of customers. This includes different sizes, shapes, atomization flow rates and particle sizes to meet the requirements of different application scenarios.

System compatibility: The compatibility of the atomizer with the customer's existing system will be fully considered during the design to ensure that it can be seamlessly integrated into end products such as medical devices, humidifiers, and industrial spraying equipment.

5. Quality control and testing

Strict quality inspection: During the production process, Saida Piezoelectric uses advanced testing equipment and technology to conduct a full range of quality inspections on Piezo Atomizer Disc. This includes material performance testing, atomization effect testing, durability testing, etc., to ensure that each atomizer meets high quality standards.

Continuous improvement: The company is committed to continuously improving the performance and quality of its products through technological innovation and process improvement. Through close cooperation with customers, feedback information is collected and product design and manufacturing processes are continuously optimized.

English

English 中文简体

中文简体