Precision Laser Micro-hole Processing Technology Manufacturers

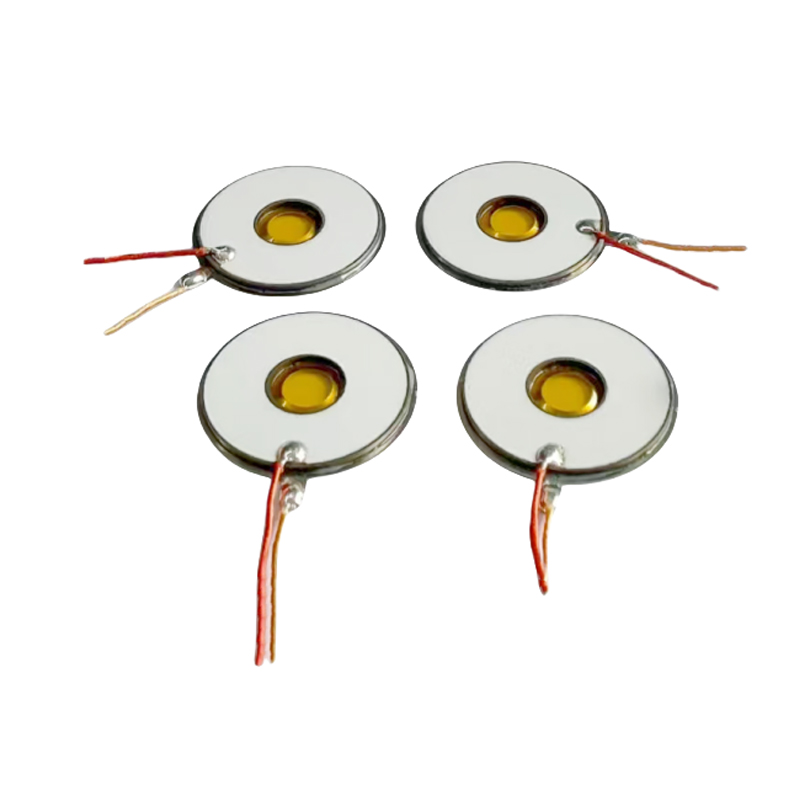

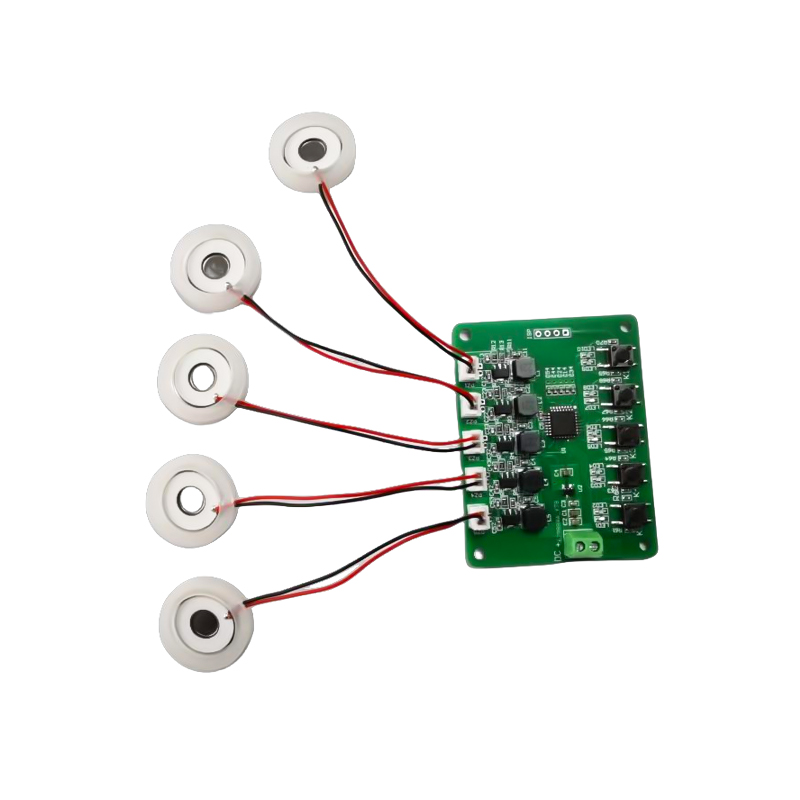

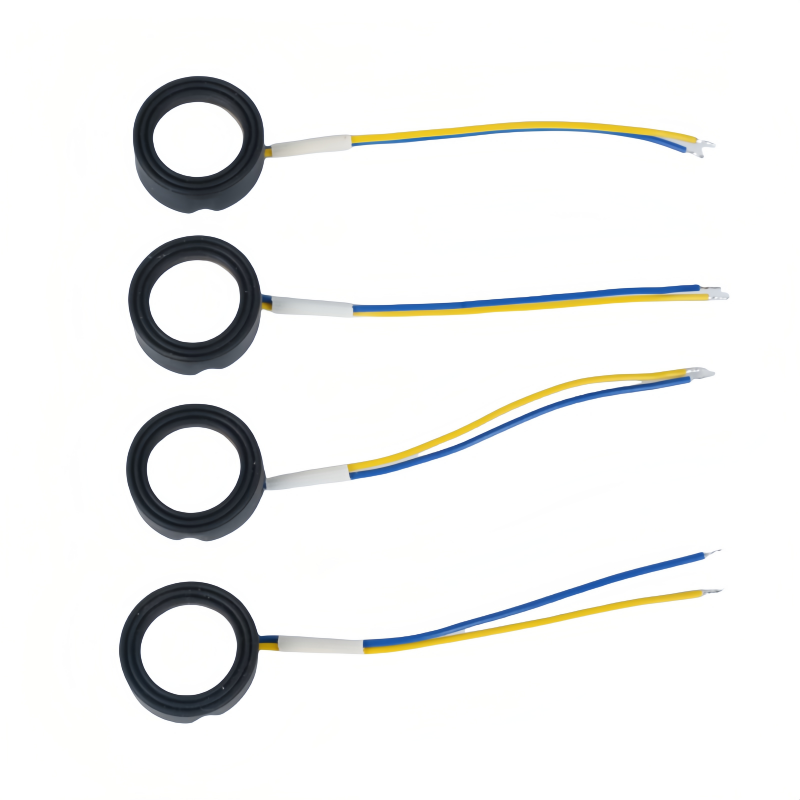

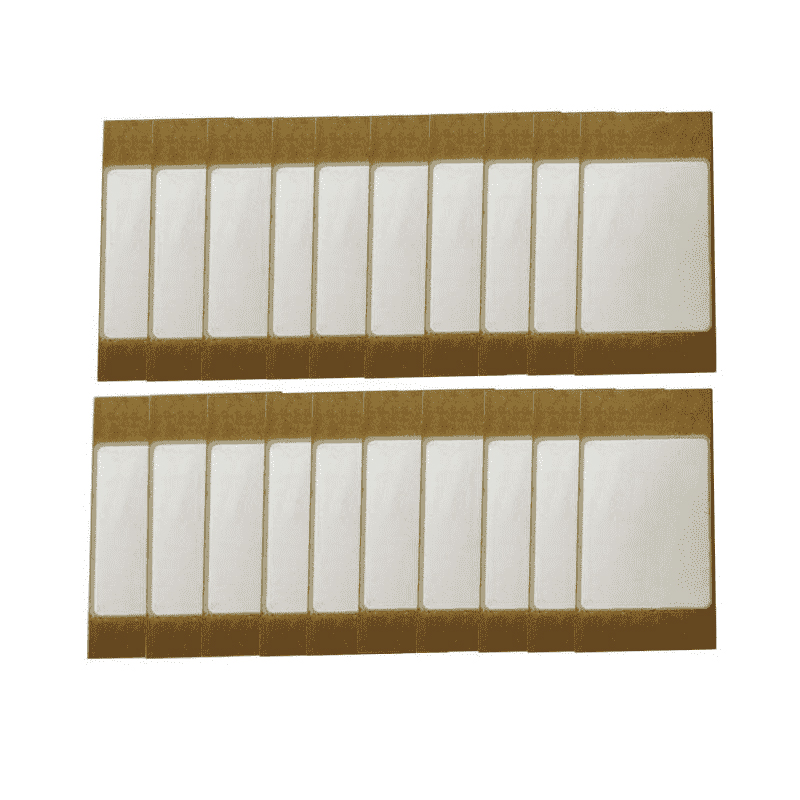

Laser microporous processing can be customized for customers with different requirements of precision microporous, our smallest microporous φ2μm maximum microporous φ30um has a very high processing accuracy, applicable to stainless steel materials, and titanium alloy materials. We can realize complex microporous shapes and array layouts to meet the strict requirements of microporous processing for high-end electronic filters, water purifier filters, medical devices, precision instruments, and other industries.

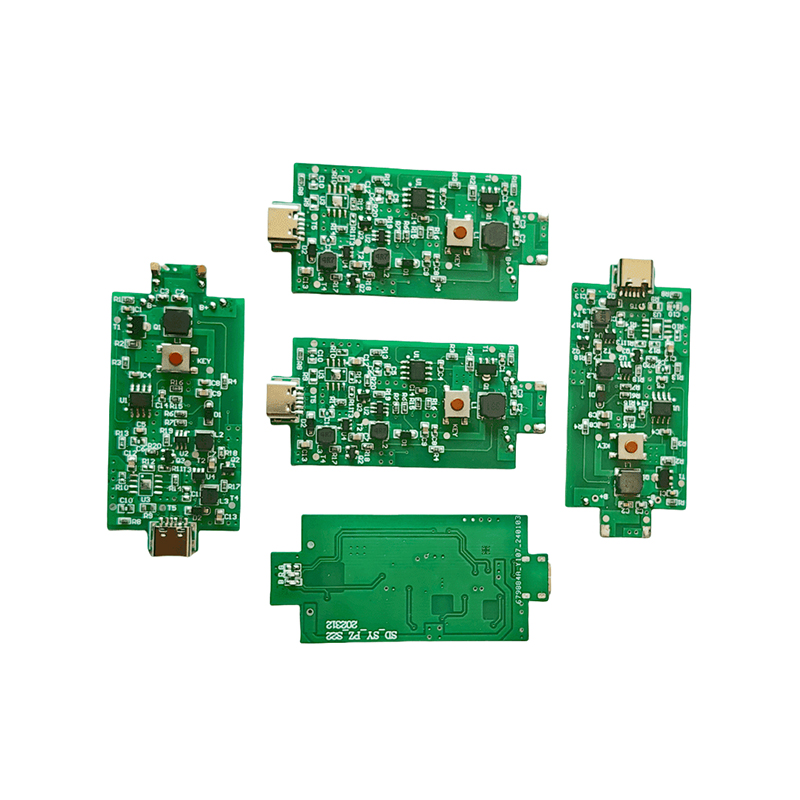

Saida Piezoelectric is a globally renowned technology-based enterprise specializing in the production and manufacturing of medical atomization related products, we are China Precision Laser Micro-hole Processing Technology Manufacturers and Custom OEM/ODM Precision Laser Micro-hole Processing Technology Company, We have been committed to the innovation, research and development, and promotion of ultrasonic piezoelectric ceramics, lead-free atomization products, electronic components, and related PCBA design solutions. Our goal is to improve people's quality of life through technology, and achieve a more efficient, green, and sustainable future for society.

Since its establishment in April 2011, the company has been at the forefront of technological development, with an outstanding research and development team, advanced production and manufacturing equipment, and precision testing equipment. We cover a wide range of ultrasonic atomization products in our professional field, including lead based and lead-free medical inhalable atomization tablets, humidifier atomization tablets, essential oil atomization tablets, industrial atomization tablets, as well as sensing products related to ultrasonic piezoelectric and PCBA driving solutions. We not only focus on in-depth technological research and development, but also actively apply technological achievements to practical life, so that technological products can truly serve and benefit society, making the world more exciting and beautiful.

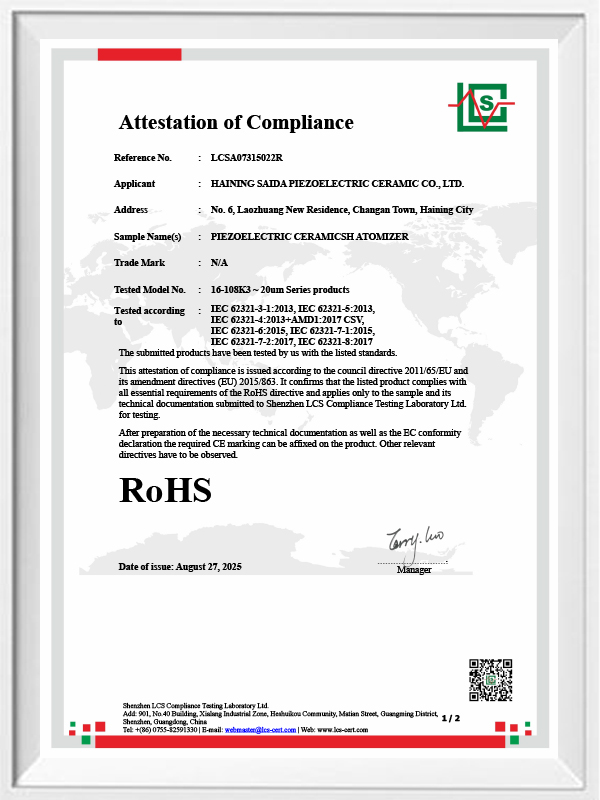

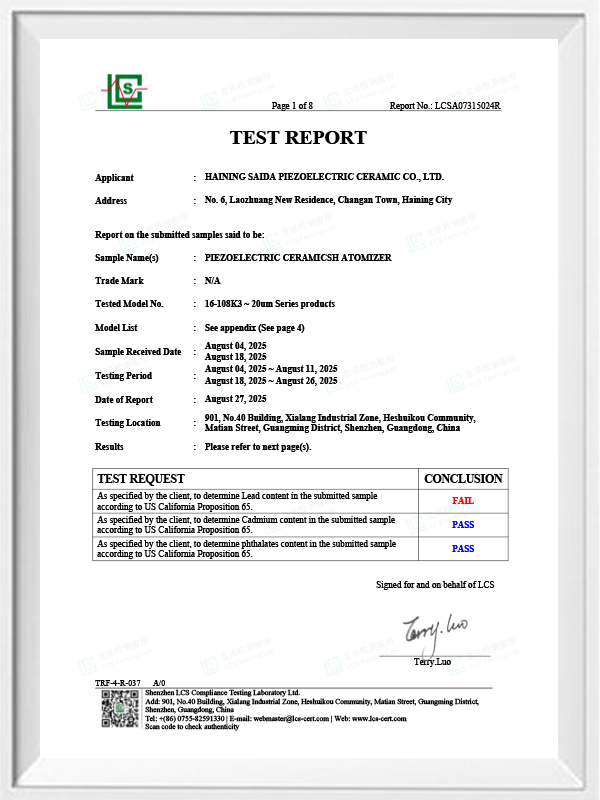

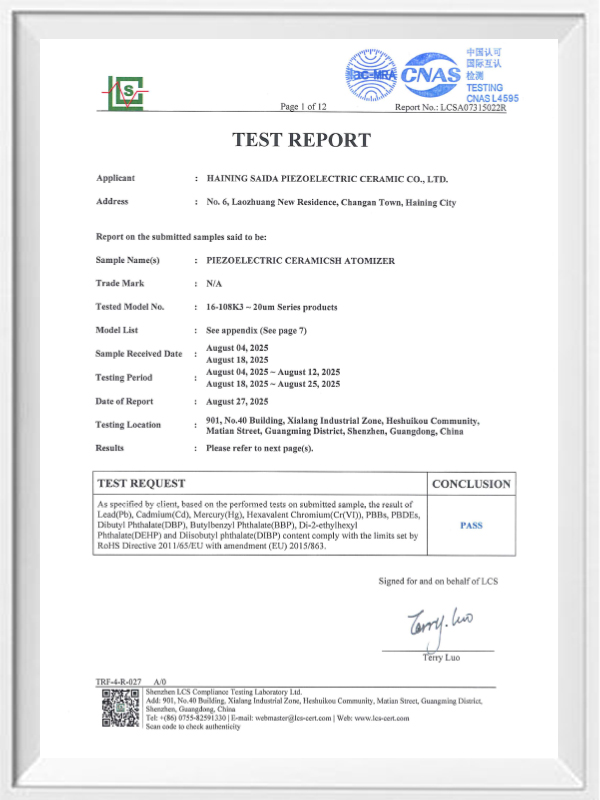

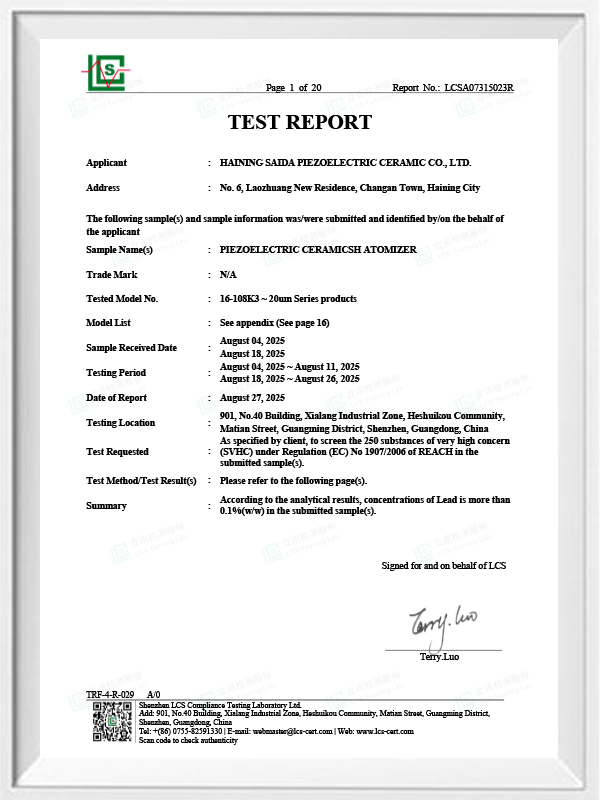

Certification

Our company's medical inhalable piezoelectric atomization series products have all passed the certifications required for export standards. They include ROHS certification, ISO9001 quality system certification, health system certification GB/T45001-2020/ISO 45001:2018, GB/T28001-2001 idt OHSAS18001:1999 Occupational Health and Safety Certification, environmental system certification GB/T24001-2016/ISO 14001:2015, California Proposition 65, REACH, and the medical atomization products have also been certified by the U.S. FDA.

news

-

Industry news

What Are the Key Benefits of Using Piezo Atomization Chips...

Introduction In the medical device industry, innovations in technology continually enhance treatment effectiveness, safety, and comfort for patients. One such breakthrough is the integration of piezo atomization chips, w...

-

Industry news

How Do Humidifier Discs Work to Maintain Optimal Humidity ...

Humidity plays a vital role in creating a comfortable living environment, particularly in regions where dry air can lead to health problems such as dry skin, respiratory issues, and discomfort. Humidifiers are essential ...

-

Industry news

How Do Medical Piezoelectric Ceramic Discs Benefit Patient...

Introduction to Medical Piezoelectric Ceramic Discs In recent years, advancements in non-invasive medical treatments have led to the introduction of innovative technologies that offer patients effective and minimally dis...

Precision Laser Micro-hole Processing Technology Industry Knowledge Extension

How do parameters such as laser power, pulse frequency, and scanning speed affect the quality of Precision Precision Laser Micro-hole Processing Technology Technology?

Influence of laser power

Laser power is one of the core parameters that determine the processing effect. It directly determines the energy density of the laser beam when it acts on the material. Too high power may cause excessive melting or even vaporization of the material, resulting in irregular hole walls or expansion of the heat-affected zone (HAZ); while too low power may not effectively penetrate the material, resulting in processing failure. Accurate control of laser power is the key to achieving high-quality micro-hole processing.

In our Precision Precision Laser Micro-hole Processing Technology Technology, we use advanced laser equipment and precision control systems to ensure high-precision micro-hole processing on materials such as stainless steel and titanium alloys. For example, our Precision Precision Laser Micro-hole Processing Technology Technology technology can achieve micro-holes with a minimum of φ2μm and a maximum of φ30μm, meeting the strict requirements of medical devices and precision instruments for micro-hole size. This high-precision processing capability has been widely used in products such as medical atomizers and water purifier filters.

The selection of laser power also needs to consider the characteristics of the material. For example, for high reflectivity materials (such as copper and aluminum), we adjust the laser power and wavelength to reduce reflection loss and ensure processing efficiency and quality. For heat-sensitive materials, we reduce the heat-affected zone and avoid material deformation or damage by reducing power and optimizing processing parameters.

The role of pulse frequency

The pulse frequency determines the number of times the laser energy acts on the material per unit time. High pulse frequency can improve processing efficiency, but may cause heat accumulation and affect the quality of the hole wall; low pulse frequency helps to reduce the heat-affected zone, but will reduce the processing speed. The choice of pulse frequency requires finding a balance between efficiency and quality.

In our processing, we rely on advanced automatic laser drilling machines and precision testing equipment to flexibly adjust the pulse frequency according to customer needs. For example, in the manufacture of medical atomizers, we ensure the consistency of micropore shape and array layout by accurately controlling the pulse frequency, thereby improving the performance and reliability of the product. For micropore processing of complex shapes, we achieve high-precision processing effects by adjusting the pulse frequency and laser energy distribution.

The pulse frequency is closely related to the thickness and hardness of the material. For thicker or harder materials, we usually use higher pulse frequencies to improve processing efficiency; for thinner or softer materials, we use lower pulse frequencies to reduce the heat-affected zone.

Optimization of scanning speed

The scanning speed directly affects the residence time of the laser beam on the material surface. Too fast speed may lead to insufficient processing and incomplete micropores; too slow speed may cause overheating of the material, resulting in rough or deformed hole walls. Optimization of scanning speed is an important part of achieving high-quality micropore processing.

In our process flow, we optimize the scanning speed and combine testing equipment such as particle analyzers and metallographic microscopes to ensure that each process meets the highest standards. For example, in the micropore processing of water purifier filter elements, we achieve high-precision processing of complex micropore shapes by accurately controlling the scanning speed to meet customers' requirements for material physical and chemical properties and high-precision geometric dimensions.

The selection of scanning speed also needs to consider the synergistic effect of laser power and pulse frequency. Through experiments and data analysis, we have established a complete set of parameter optimization models that can quickly determine the optimal scanning speed according to different materials and processing requirements.

Application of Precision Laser Micropore Processing

Precision laser micropore processing technology is widely used in many fields. In the field of medical devices, we use high-precision micropore processing technology to manufacture excellent medical atomizer sheets for atomization treatment of inhalable drugs. In the field of electronic components, we provide high-precision micropore processing services for high-end electronic filter elements and precision instruments to ensure product performance and reliability.

In the field of environmental protection, our laser micropore processing technology is widely used in the manufacture of water purifier filter elements. By precisely controlling the size and distribution of micropores, we can significantly improve the filtration efficiency and life of the filter element. Our technology is also used in the aerospace field to provide high-quality micropore processing services for precision sensors and engine components.

English

English 中文简体

中文简体